N-Octyl Bromide: A Deep Dive into Its Journey, Science, and Applications

Historical Development

The roots of N-Octyl Bromide tie back to the era when organic halides started transforming both academic laboratories and fine chemical industries. Chemists first encountered this compound after the widespread adoption of Grignard reactions, which opened the door for synthesizing various alkyl halides. Over the decades, curiosity grew—not just out of a desire for new molecules, but from a need for reagents that could drive advancements in drug development and materials science. Chemical catalogs began featuring N-Octyl Bromide more frequently in the late twentieth century, largely due to interest from organic synthesis and industrial surfactant creation.

Product Overview

N-Octyl Bromide, also known as 1-Bromooctane, has earned a stable spot in research labs and manufacturing facilities. This alkyl bromide does not grab headlines, but it’s a familiar sight for chemists working on alkylation or seeking to build more complex carbon skeletons. As a straight-chain bromide with eight carbon atoms, its value comes from its predictable reactivity and compatibility with a range of organic transformations. Whether you are preparing new active pharmaceutical ingredients or seeking building blocks for specialty polymers, N-Octyl Bromide keeps showing up as a steady choice.

Physical & Chemical Properties

On the bench, N-Octyl Bromide flows as a colorless to pale yellow liquid with a gentle, fruit-like odor that’s not hard to spot among halogenated solvents. The boiling point hovers around 201 to 203°C, which means you need proper ventilation and temperature control if you’re distilling or handling large quantities. At room temperature, it won’t evaporate like diethyl ether, but it still creeps up on you if left unattended. Reactivity centers on the bromine atom; it leaves as a classic nucleofuge in substitution reactions. The eight-carbon backbone offers enough bulk for hydrophobicity without complicating solubility in organic media. Its molecular weight clocks in at about 193 g/mol, and it sinks in water, forming an oily layer beneath the surface.

Technical Specifications & Labeling

Bottles of N-Octyl Bromide arrive clearly marked: chemical name, CAS number (111-83-1), hazard pictograms, and concentration or purity, usually higher than 98%. Labels feature precaution statements about flammability and environmental hazards. As a regulated hazardous substance, shipping containers come reinforced, often with secondary containment, and include safety data sheets with recommendations about storage, shelf life, and incompatibles. You’ll often see lot numbers and manufacturing dates—essential for traceability, especially if using the product for regulated pharmaceutical or agrochemical processes.

Preparation Method

Synthesis of N-Octyl Bromide usually starts from 1-octanol or n-octane. Classic methods call for reacting 1-octanol with hydrobromic acid (sometimes aided by strong dehydrating agents like sulfuric acid), generating the bromide in straightforward substitution. Some manufacturers prefer using phosphorus tribromide, which streamlines the process and lowers the formation of byproducts. Scale-up for industrial batches sticks to tried-and-true protocols, as alterations in stoichiometry or temperature often push up the risk of over-bromination or side reactions. Recovery and purification often include phase separation, distillation under reduced pressure, and activated carbon to remove color bodies.

Chemical Reactions & Modifications

Chemists reach for N-Octyl Bromide during alkylation steps, with the bromine acting as a classic leaving group. In nucleophilic substitution reactions, it hands off the octyl chain to various nucleophiles—amines, alcohols, thiols. Many surfactants or phase transfer catalysts start life from N-Octyl Bromide, which couples smoothly with nitrogen or oxygen centers. The reactivity opens pathways for Grignard formation, Wurtz couplings, and halogen exchange reactions. Modifications using N-Octyl Bromide allow the introduction of a long, flexible alkyl chain into more compact molecules, shifting solubility from hydrophilic to hydrophobic.

Synonyms & Product Names

You’ll see N-Octyl Bromide go by several other names in the literature, which can get confusing unless you keep track. Common synonyms include 1-Bromooctane, Octyl Bromide, and Bromon-octane. Catalogs sometimes reference the IUPAC name or abbreviate the compound as C8H17Br. Researchers and suppliers handle the term interchangeably, and a quick scan of safety data sheets or reagent catalogs brings up these alternates side by side.

Safety & Operational Standards

Working with N-Octyl Bromide takes more than basic precaution. This chemical irritates the skin, eyes, and respiratory tract; prolonged exposure can cause headaches or dizziness. Safety goggles, gloves, and lab coats never feel like overkill, especially with the potential for splashes or vapor inhalation. Laboratories enforce strict containment practices, with chemical fume hoods and well-marked spill kits. Regulatory compliance draws on the Globally Harmonized System, and waste streams go into designated halogenated-organic solvent bins to protect both staff and the environment. Training isn’t optional; anyone handling N-Octyl Bromide needs to know emergency procedures, from eyewash station use to evacuation plans.

Application Area

Most who handle N-Octyl Bromide are not strangers to organic synthesis, particularly in the context of pharmaceutical screening or materials science. Researchers use it to build custom surfactants, detergents, and emulsifiers, designing molecules with nuanced amphiphilic behavior. It turns up in synthesis protocols for active pharmaceutical ingredients, lubricants, and even as an intermediate in the modular development of catalysts or ligands. Electronics manufacturers sometimes employ modified octyl bromide derivatives as part of specialty cleaning fluids or in the preparation of antistatic coatings.

Research & Development

Recent years have pushed N-Octyl Bromide beyond classic uses. Scientists explore the compound’s potential for late-stage functionalization in drug discovery programs. It serves as an essential reference point in developing new protocols for carbon-chain elongation or branching. Process chemists develop greener, waste-minimizing routes for its preparation, seeking alternatives to heavy metals or corrosive acids. In preparation of advanced materials, octyl-modified fragments derived from this molecule boost compatibility with polymers, adjusting melting temperatures or mechanical flexibility.

Toxicity Research

Environmental and occupational health researchers continue testing the effects of N-Octyl Bromide. In acute toxicity studies, the major concern focuses on irritation to the mucous membranes and temporary impacts on nervous system function after inhalation. Chronic exposure, while not common in well-regulated settings, can raise the risk of liver and kidney stress. In aquatic toxicity screens, it shows moderate persistence, with breakdown times that extend into weeks under natural conditions. Disposal methods aimed at neutralization lessen the risk of groundwater contamination. As more industries turn toward sustainable chemicals, fresh toxicity screens assess the compound’s longer-term environmental profile.

Future Prospects

People often ask where chemicals like N-Octyl Bromide will fit in a future less dependent on fossil resources. Research already points toward bio-based feedstocks derived from plant oils, aiming to swap petroleum-derived octanols for renewable sources. Automation in chemical manufacturing stands to increase safety margins, reducing human exposure and improving quality. As computational chemistry grows, predictive models help screen new derivatives for both performance and reduced toxicity, potentially guiding the development of next-generation surfactants or pharmaceutical intermediates. Industry and academia both watch regulatory landscapes closely, balancing innovation and public safety. The versatility and reliability of N-Octyl Bromide place it in a position to evolve with shifting priorities, staying useful as science and technology push forward.

Understanding N-Octyl Bromide’s Place in Chemistry

A lot of folks don’t hear about N-Octyl Bromide outside of a lab or an industrial setting. This clear liquid, carrying a faint odor, shows up in a world built on chemical reactions. If you step foot into any decent organic chemistry lab, you’ll spot pure bottles of this stuff tucked on the shelves. The main draw for chemists? It’s a simple way to introduce an eight-carbon chain, or octyl group, into another molecule during a process called alkylation.

How Labs Use N-Octyl Bromide

Chemists like me have counted on N-Octyl Bromide for decades. The core of its use lies in synthesis—creating larger, more complex molecules by piecing together basic building blocks. This compound often reacts with other chemicals that contain an active hydrogen, such as amines or alcohols. These types of processes matter a lot when you’re producing specialty chemicals or prepping ingredients for pharmaceuticals or plastics. Even if you’re not thinking about every shampoo bottle or plastic part, chances are this molecule helped somewhere along the line.

For those outside the lab, hearing about N-Octyl Bromide usually happens only during environmental spill reports or industrial news. Keeping the public safe means handling it with secure protocols. Direct skin or lung exposure doesn’t feel good, and repeated exposure could be harmful according to safety data sheets from the European Chemicals Agency. It’s tightly regulated, and workers wear gloves and masks when moving it around. Mistakes can be costly—not just in financial terms, but also for worker safety.

Industrial Applications Beyond the Lab

Factories use N-Octyl Bromide to build surfactants. These make products like cleaning agents and detergents work better, helping water grab onto oil or grime and wash it away. The world relies on surfactant chemistry to keep everything from clothes to industrial equipment clean. The process to make these surfactants starts with compounds like N-Octyl Bromide, which introduce the correct tail to the surfactant molecule for tackling tough messes.

Pharmaceutical firms turn to this chemical for synthesizing intermediates—key stages on the route to a finished drug. Without reagents like this, making advanced medicines would slow down. Research teams also test new molecules using the octyl group, searching for fresh drug candidates for neurological and cardiovascular conditions. My own graduate work occasionally required this liquid for making custom compounds to probe biological systems.

Environmental and Health Considerations

Using chemicals like N-Octyl Bromide means keeping a close eye on waste disposal. Responsible companies work hard to prevent leaks into water or soil. Many follow programs such as the Responsible Care Initiative, which stresses continuous improvement in chemical handling and spills. The toxicology research suggests that, given careful use, the risk drops sharply. Better monitoring equipment and safety training have made a real difference. With growing pressure from communities and regulators, industry has moved to greener chemistry, looking for alternatives or ways to recycle solvents and by-products.

Thinking Forward

The need for a molecule like N-Octyl Bromide reflects bigger trends in science and industry. As demand rises for innovative polymers and tougher surfactants, companies want to either streamline the use of these building blocks or replace them with safer alternatives. Green chemistry studies are chasing these goals, trying to keep chemical processes smart and safe. Cutting waste and improving product safety help both manufacturers and the neighborhoods nearby. The story of N-Octyl Bromide captures the balance between sophisticated science and everyday safety—the kind of balance that shapes the products we rely on every day.

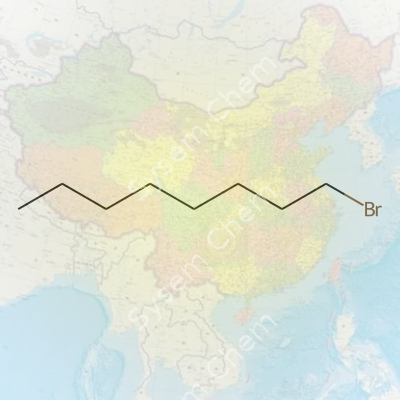

Unlocking the Formula: C8H17Br

N-Octyl Bromide might sound like a tongue-twister, but at its core, this compound follows a pretty straightforward formula: C8H17Br. In chemistry class, I remember drawing lines and counting hydrogens just to make sure nothing got left behind. Eight carbon atoms make up the backbone, seventeen hydrogens wrap around those carbons, and bromine comes in to finish the job. That single bromine atom often means a lot more than its size suggests—especially where reactivity is involved.

Why Care About C8H17Br?

N-Octyl Bromide, with its straight-chain structure, finds its way into labs and manufacturing plants around the globe. Organic synthesis depends on intermediates that can be relied on to react in predictable ways. The carbon-bromine bond has a knack for catching attention because it’s a good leaving group—one of those terms you only appreciate after enough frustrating reactions in a college lab. This reliability pushes chemists to reach for N-Octyl Bromide when trying to build more complex molecules, whether for materials, surfactants, or pharmaceuticals.

Looking back, I remember how much the smallest change to a chain of carbon atoms changed the way molecules connected. Swapping a single chlorine for bromine or extending a carbon chain sometimes made all the difference. N-Octyl Bromide rarely sits alone in a bottle. Instead, it acts as launching pad, helping other molecules take shape. Dialing in the exact formula—C8H17Br—means there’s less room for error, and reactions are less likely to stall or veer off track.

Human Safety and Environmental Considerations

Safety measures must follow whenever dealing with organobromides. I’ve seen firsthand how a lapse can lead to skin or respiratory issues. N-Octyl Bromide, like its cousins, asks for careful handling—gloves, well-ventilated hoods, and proper disposal matter just as much as the purity of reactants. Historically, brominated compounds have left their mark on environmental health. Those used without proper containment sometimes persisted for years, leaching into groundwater or affecting local wildlife. Fortunately, tighter regulations and stricter workplace standards cut back on unnecessary risks. Still, everyone present in a space with N-Octyl Bromide needs up-to-date safety training, not just a label and a hope that nothing spills.

Solutions for Safer and Smarter Use

Practical solutions work best when they come from shared experience. Substituting less hazardous chemicals, when feasible, can make a meaningful difference. Automated systems that limit human exposure and digital logs that track container movement also remove plenty of guesswork. Establishing closed-loop recycling, where excess or waste bromides go back into the supply chain, cuts both costs and impact. Auditing every step in the supply process, from storage through disposal, nudges organizations away from old habits. Bringing research teams, safety officers, and environmental scientists together turns theoretical best practices into daily routines. Lessons I learned from previous missteps push me to suggest clear labeling, written protocols, and easy access to spill kits—small steps save lives and prevent costly contamination events.

Seeing Beyond the Formula

Chemistry often comes down to getting details right. Memorizing the formula C8H17Br is a step, but understanding the impacts, applications, and responsibilities rooted in that compound raises the bar for everyone who works with it. Experience, attention, and a willingness to adapt combine to keep everyone a little safer and every outcome a little more predictable.

Getting to Know N-Octyl Bromide

N-Octyl Bromide has a clear industrial purpose, finding its way into laboratories, chemical manufacturing settings, and sometimes pharmaceutical research. The liquid brings more than just a strong odor; skin or eye contact brings real risks. I remember reading through a batch of safety data sheets as a young lab tech, noticing how alkyl halides like this one ask for respect and extra attention.

Direct Hazards: Eyes, Skin, and Breathing

N-Octyl Bromide irritates eyes and skin fast. Any splash or spill can burn, itch, and leave lasting damage if not washed away in minutes. A friend of mine got a drop on her hand—she shrugged it off, but within an hour, her skin felt raw and looked red. Chemical burns aren’t worth the gamble. Gloves of strong material, usually nitrile, handle most mishaps. Ordinary latex doesn’t cut it for bigger exposures, so double-gloving gets recommended. For eye protection, wraparound safety goggles stand as the surest guard. Adding a face shield protects against splashes headed your way.

The fumes aren’t any friendlier. Even short exposure gives off a powerful chemical smell that tickles the nose and sometimes stings your throat. Any time work moves from a sealed bottle to the open air, it should happen inside a chemical fume hood. The right ventilation cuts risks by moving those fumes away before they hit your lungs.

Storage and Spill Response

This liquid doesn’t enjoy open air for long. Humidity and heat shift its stability, and it reacts stubbornly with metals and strong bases. I always stored it in tightly sealed glass containers, inside well-marked, ventilated cabinets, away from sunlight. Keeping chemicals upright and away from acids helps avoid those surprise reactions that tend to turn simple accidents into bigger problems.

If something spills, it’s tempting to just grab a paper towel and mop it up. For N-Octyl Bromide, dry absorbent pads and a dedicated spill kit work better. All waste goes straight into a labeled hazardous waste container, not into the regular trash. Not caring for small spills quickly enough can turn lab benches into sticky, hazardous zones, with fumes lingering hours afterward.

Fire and Emergency Preparation

N-Octyl Bromide catches fire at much lower temperatures than water boils. Flames start before you know it if hot equipment sits nearby or if a static spark lights up the vapor. I always made sure our lab kept carbon dioxide and dry chemical fire extinguishers within reach, never just water. Knowing how to use that extinguisher, and doing a monthly equipment check, becomes second nature after you hear how fast things can escalate.

Training and Supervision Keep People Safe

Set procedures protect not only the people who handle N-Octyl Bromide every day, but also those working down the hall. Regular safety training sessions help everyone know what to do, and emergency practice—like eye wash drills, spill response, or evacuation plans—raises confidence on nerves’ worst day. The value of a watchful lab supervisor can’t be overstated. I saw how close calls shrink when new team members get patient mentoring, not just a manual left on the counter.

Getting Disposal Right

N-Octyl Bromide doesn’t belong in sinks or landfills. Most places ask labs and factories to tag all hazardous waste and call in certified disposal services. This avoids fires, groundwater contamination, and the sort of surprises that stick around longer than any person working with it. Big organizations often have their own tracking software and safety audits, but even small setups can keep careful logs and follow local rules.

Understanding the Numbers Behind Purity

People working with N-Octyl Bromide want a clear specification: they expect purity levels above 98%. Chemists keep a close eye on that percentage. If the purity drops, test results start to drift, and end products don’t match up batch after batch. Top-grade research chemicals such as N-Octyl Bromide often appear with certificates listing GC or HPLC purity—sometimes as high as 99% or above, usually not less than 98%. Even a small amount of impurity can send synthetic chemistry off track.

Where the Numbers Come From

Let’s talk about measurement. Gas chromatography (GC) and high-performance liquid chromatography (HPLC) aren’t flashy, but they tell the story straight. They pull up peaks for possible contaminants and add confidence for the user. Water content matters too—specialists tend to check with Karl Fischer titration because water hiding in the bottle can trigger unwanted side reactions, especially when working on organometallic syntheses.

Real-Life Impact of Purity

Take an undergraduate organic lab, or a commercial plant that relies on N-Octyl Bromide as an alkylating reagent. If the bottle reads 95% instead of 99%, students or operators might waste hours tweaking their processes to fix low yields or clean up mystery reactions. Last year, I watched someone toss out a whole day's reaction because their supplier let trace impurities slip in. Time, money, and good science get wasted.

For pharmaceuticals or agrochemicals, regulatory bodies—think FDA, EMA, or China’s NMPA—want safety margins. Manufacturers choose higher-purity material to reduce risk, since leftover bromine, octanol, or related by-products raise red flags during audits and toxicological screening.

Common Specification Details

The datasheet for a trusted batch of N-Octyl Bromide usually includes:

- Purity by GC: >98%

- Where applicable, water content: below 0.2%

- Color (APHA or Hazen units): clear and colorless, usually below 10 APHA

- Acidity or bromide ions: not detected

- Physical constants: boiling point, refractive index, density (for identity confirmation)

These details give transparency. Companies ship COAs (Certificates of Analysis) so that buyers know exactly what’s in the drum or vial.

Staying Vigilant: Checking and Improving Purity

Quality starts at the source. If you’re running a lab, always ask for recent analytical certificates—not just product labels. Storage makes a difference. N-Octyl Bromide absorbs moisture and light can slowly trigger decomposition; that explains why chemical storerooms keep it in amber glass and away from heat. If possible, stash a small vial in a desiccator.

Your own checks help too. Anyone with access to basic NMR or GC equipment can spot weird signals or peaks before scaling up a synthesis. Sometimes, distillation under reduced pressure works as a last resort to bump up the purity, though most researchers prefer to buy chemicals that meet spec the first time.

Working Toward Consistency and Trust

Labs and manufacturers prefer a partner who stands by their purity numbers. Reliable suppliers document both their process and their batches. If a run falls below 98%, they don’t ship; if you ever run into an issue, reaching a real chemist at the supplier helps more than an automated email.

At every level, the real value comes from buying and using material you can trust—so that the science, safety, and production downstream never get sidetracked.

What Is At Stake With N-Octyl Bromide?

N-Octyl Bromide doesn’t show up in most households, but in labs and in chemical manufacturing, it stands out for a reason. This chemical reacts quickly, and it doesn’t like to mingle with water, air, or heat. Spill some, breathe in the fumes, or let it mix with incompatible materials, and it creates problems for both people and the environment. From real-world experience in a shared laboratory, even small mishaps—poorly sealed container, left on a warm bench—lead to headaches or even riskier outcomes, like strong odors spreading or skin irritation.

Container Choice Isn’t Just a Box-Ticking Exercise

You can’t toss N-Octyl Bromide in just any bottle. Glass offers stability. Keep plastic in the supply closet; plenty of plastics react or degrade over time, increasing the odds of leaks or chemical reactions. Go for dark glass and a solid screw-on cap, which blocks unwanted light and keeps fumes in-check. Before my first chemistry job, I never imagined screw threads could matter so much. Someone once used a push-cap, and the resulting vapor left a nasty sting in the air that lingered even after airing out the room.

Cool, Dry, and Away From Trouble

A dry, cool shelf away from sunlight sets the baseline. Heat makes N-Octyl Bromide vaporize faster, and moisture leads to slow breakdown. One cold room I worked in handled both temperature and humidity—it was worth the investment. Chemical fridges and ventilated cabinets with automatic logs keep the environment constant, so the chemical does its job and stays out of trouble. Never stack near strong acids, alkalis, or oxidizers. Overpacked storage increases the risk of accidental contact and cross-contamination, and a careless neighbor once learned that the hard way; a splash turned into a ruined batch and a lot of paperwork.

Label. Log. Repeat.

Forget a label, and someone else will, too. Permanent markers on glass work, but printed, solvent-resistant labels pay off after weeks or months. Keep a logbook or an electronic record with dates, amounts, and who placed it in the cabinet. In a team setting, shared accountability means fewer mysteries during audits or after-the-fact questions about expired chemicals. One small lab I know switched from sticky notes to properly labeled bottles and cut down confusion overnight.

Think Ahead: Safety Isn’t Optional

Good storage goes hand-in-hand with safety equipment. Gloves, goggles, and splash guards earn their place not to fill a checklist, but because an unexpected drip can cause more than inconvenience. Showers and eye wash stations nearby can turn a bad day into just an irritating one. As one former colleague said, “You only mess up handling bromides once if the eyewash is ten feet away instead of fifty.”

Solutions for Tighter Control

Improving storage often doesn’t mean new technology. Clear policies, staff briefings, spot checks, and a culture that calls out shortcuts save hassle and expense over time. Training matters most—that’s true after seeing rookie mistakes from new hires trying to rush through a procedure. Small investments—new shelving, a lockable cabinet—save money and panic later. Sustainable handling often relies more on people than gadgets, and shared knowledge gets everyone home safe.