Isobutyl Chloride: A Practical Perspective on an Industrial Chemical

Historical Development

Industry leaned into chemicals like isobutyl chloride as early as the 20th century when chemical synthesis routes started shaping up modern manufacturing. Folks in labs found out you can get it from the reaction between isobutanol and hydrochloric acid, a discovery that led to improved paint removers, pharmaceuticals, and fragrances. Back then, using isobutyl chloride marked a step forward in efficiency for many sectors. It’s a story of progress built on solving practical problems, streamlining production, and reducing waste in ways that made a real difference.

Product Overview

Most people never see isobutyl chloride in daily life, but it often supports the backbone of the industries that keep everyday goods accurate, safe, and affordable. It brings reliability to producers because it acts as a key intermediate, meaning it helps transform raw materials into something far more valuable. The fact that it holds such a spot in the supply chain tells you it has earned its keep through years of tough industrial scrutiny. If you’ve opened a bottle of perfume, applied a pharmaceutical cream, or driven a car with special coatings, there’s a solid chance this chemical played a part somewhere along the way.

Physical & Chemical Properties

Isobutyl chloride doesn’t bring surprises – it’s a clear, colorless liquid, and you can smell it if the bottle tips too far. Its boiling point (68°C) sits in a range that suits distillation setups; people in chemical plants value that kind of trait because it lets them purify and move the stuff without much hassle. With a molecular formula of C4H9Cl, it sits in the family of alkyl chlorides. It evaporates quickly, feels slippery to the touch, and mixes with organic solvents better than with water. Its density (around 0.87 g/cm3) also lends itself to physical separation in multi-phase reactions.

Technical Specifications & Labeling

Every drum or bottle sporting isobutyl chloride needs to follow strict technical guidelines. Specifications track purity (usually above 98%), with clear traceability on water content, color, acidity, and related impurities. Labels stick close to regulations, showing proper hazard pictograms, UN numbers, and detailed instructions on storage: cool, away from heat and moisture, with proper venting. This level of detail turns logistical work into a daily safety practice. Global chemical markets won’t clear shipments unless packaging and labeling tick every regulatory box, including GHS labeling conventions and transportation documentation.

Preparation Method

The classic way to make isobutyl chloride involves bubbling hydrochloric acid through isobutanol with a little zinc chloride catalyst. The reaction runs at room temperature or slightly warmer. In big plants, reactors take in raw isobutanol and acid, and out comes a steady stream of product, ready for the next stage. Distillation separates what you need from leftovers. For small-scale setups, glassware and fume hoods work fine, but industrial outfits use stainless steel reactors with advanced controls to keep everything in check. Any process worth repeating must wring every drop of efficiency from the available steps, and the preparation method of isobutyl chloride fits this creed.

Chemical Reactions & Modifications

Isobutyl chloride opens doors to a closet of modifications. It jumps at nucleophilic substitution, swapping out the chloride for other groups to produce smooth intermediates for everything from pesticides to pharmaceuticals. Grignard reactions, which rely on magnesium and these alkyl chlorides, feed into synthesis chains that spin out building blocks for paint additives, flavors, and specialty plastics. Folks in custom synthesis labs count on its reactive nature because it unlocks many carbon–carbon bond formations. Easy reactivity means more flexibility for research chemists and process engineers who have deadlines and budgets to meet.

Synonyms & Product Names

Anyone working with this chemical soon learns its other names: 1-chloro-2-methylpropane, isobutylchlorid (in some European contexts), and chlorisobutane. These synonyms pop up on MSDS sheets, order forms, or customs manifests, often depending on where the batch is heading. Keeping a tight handle on these names avoids confusion during shipping or regulatory checks, especially in global marketplaces where naming conventions vary.

Safety & Operational Standards

Safety officers insist on gloves, goggles, and good ventilation wherever isobutyl chloride gets used. It doesn’t forgive mistakes – inhaling the vapor can irritate lungs and eyes, and contact with skin stings. National standards require spill kits and fire extinguishers nearby because its vapors form flammable mixtures with air. Every lab and plant operator working with isobutyl chloride depends on risk assessments that consider exposure limits, PPE requirements, and emergency practice drills. Meeting OSHA and REACH guidelines remains non-negotiable for anyone serious about health and safety.

Application Area

Isobutyl chloride translates chemistry into application. It finds a place in drug synthesis where tight controls over purity and by-products matter. Agrochemical firms include it in processes to give pesticides their chemical kick. Paint manufacturers lean on it for creating resins that coat buildings and cars. Fragrance and flavor companies hit benchmarks for consistency thanks to its used in intermediates, making sure any new batch of product matches the company’s gold standard. Anyone aiming to scale up organic syntheses will likely cross paths with isobutyl chloride.

Research & Development

Researchers press ahead on developing greener routes for making and using isobutyl chloride. Some teams hunt for bio-based feedstocks that could trim the industry’s carbon footprint, eyeing renewable sources where isobutanol gets made from sugar or waste biomass. Others look at catalysts that run reactions faster, cleaner, and at lower temperatures. In pharma and specialty chemicals, R&D folks tweak protocols aiming for higher yield and fewer by-products. Every recess of the specialty chemical world keeps pushing for better ways to handle, modify, and dispose of isobutyl chloride, with safety and cost always front and center.

Toxicity Research

Toxicologists measure how exposure to isobutyl chloride affects the body, focusing on irritation, liver metabolism, and long-term occupational risks. Lab studies found that even low-level inhalation can cause headaches or coughing, while higher doses risk chemical burns and lung damage. Data sets from animal models and workplace monitoring shape official limits for permissible exposure (like 50 ppm over an eight-hour shift). The goal stays clear: stop injuries before they happen, catch leaks fast, and build trust between employers and workers, keeping clear documentation on all incidents and near-misses.

Future Prospects

The outlook points to steady demand for isobutyl chloride, carried by its role in pharmaceuticals and coatings. Growth in Asia’s chemical manufacturing builds new supply routes, and tighter rules in Europe and North America drive innovation in process safety and emissions. In the lab, chemists chase ways to convert waste products into useful intermediates using isobutyl chloride chemistry, aiming to stretch each raw material further. Automation and smart sensors promise safer handling in plants, while fresh research promises new derivatives that cut environmental risks. It remains a workhorse in industry, with every improvement rippling out to touch products we rely on every day.

Practical Uses in the Chemical Industry

Walk into a chemical plant producing specialty chemicals, and you’ll likely find drums of Isobutyl Chloride stacked near the reactors. This compound often works as both a building block and a starting point in manufacturing other goods. For anyone who’s ever been in an industrial lab, the sharp, unpleasant smell is unmistakable. It doesn’t win any popularity contests for its aroma, but it’s a workhorse behind the scenes.

Most folks never hear about Isobutyl Chloride, but they rely on products born from it every day. Manufacturers often use it to make pharmaceuticals—drugs that treat everything from mild pain to chronic disease. Isobutyl Chloride helps create active ingredients in these medicines. It’s built into the supply chain, quietly linking raw petrochemical feedstocks to complex products on pharmacy shelves.

Outside of medicine, it carves out a niche in making pesticides and herbicides. Growing food at scale takes more than good soil, and farmers need clever chemistry to protect crops. Companies tap Isobutyl Chloride to design reagents used in these crop protection products. Chemists value its reactivity, controlling reactions so they get the molecules they want without sidetracked by unwanted byproducts.

Not Just Labs: Everyday Connections

People think little about what keeps vehicles, plastics, and electronics running smoothly. Chemicals like Isobutyl Chloride grease the wheels of progress, sometimes literally. Lubricant manufacturers turn to it during the creation of specialized oils, suitable for engines under stress. That bottle of motor oil at the auto parts store might carry a chemical fingerprint left by a step involving Isobutyl Chloride.

In solvent production, it acts as an intermediate, bridging gaps between raw materials and finished products. Solvents extracted and distilled from petroleum often require tuning. Sometimes, chemists introduce Isobutyl Chloride to push a reaction one way or another, yielding solvents that clean factory equipment or make paints spread evenly on your living room wall.

Health and Safety: Risks That Need Attention

Experience in chemical manufacturing teaches that every powerful tool cuts both ways. Isobutyl Chloride isn’t a friendly neighbor if mishandled. Breathing its vapors irritates the eyes and lungs. Spills corrode skin and contaminate water supplies. I’ve seen safety officers wince at even small leaks. Workers handle it wearing gloves, goggles, and masks for good reason.

Strict regulation sets boundaries around how much can be released and how it’s stored. Plants invest in proper ventilation and containment. Environmental agencies track its movement from factories to landfills. These practices don’t exist just for show—they prevent accidents and limit harm, drawing lessons from past incidents where complacency did real damage. Anyone storing or using it needs strong protocols and responsive emergency plans on hand.

Better Ways Forward

Chemists keep searching for smarter routes—processes that use less hazardous intermediates or recycle more of the chemicals involved. Green chemistry initiatives push for alternatives that offer the same utility with less risk. Replacing Isobutyl Chloride takes innovation, collaboration, and solid incentives from government and industry.

Still, as long as it remains part of the industrial toolkit, responsibility follows. Every manufacturer handling this compound owes workers, neighbors, and the environment a safe, careful approach. Better labels, clearer safety documentation, and investments in training make a real difference. That’s how progress happens: by knowing the risks, respecting them, and demanding better from the systems that surround us.

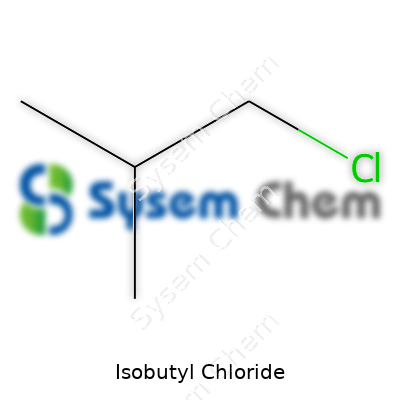

Recognizing the Right Formula: C4H9Cl

Isobutyl chloride, with its formula C4H9Cl, is not just another compound taking up space in a lab inventory. Behind these symbols sits a mix of science and industry that shapes products and processes found in everyday life. Anyone dealing with chemicals benefits from knowing not just the name, but also the structure and formula—but not for the sake of trivia. It's about safety, readiness, and clear communication.

Digging Into the Structure

This molecule belongs to a group called alkyl halides. In isobutyl chloride, a chlorine atom has replaced a hydrogen on the side branch of a four-carbon chain. That swap changes how the molecule behaves both in the lab and in the environment. A person with chemistry in their background remembers how small structural differences bring totally different reactions. The isobutyl group gives a slightly branched arrangement—one carbon sticks out from the main chain. I remember working on a synthesis in graduate school and watching even a small mix-up between n-butyl and isobutyl groups bring an experiment to a halt. Even on paper, formulas make a difference.

Personal Experience With Chemical Safety

Many forget the safety training until the day something goes wrong. Isobutyl chloride demands respect. It irritates eyes and skin, and breathe in those vapors and you know right away something’s wrong. In the lab, not knowing the correct chemical formula could mean a storage or waste disposal error. Fact: Halogenated organics get handled differently from pure hydrocarbons when it comes to both storage and spills. Mixing things up risks fines or worse. I’ve seen extra paperwork slow projects by days because of uncertainty about formulas on a shipping label.

Applications Touching Everyday Life

C4H9Cl isn’t just for chemists. This compound sits at a crossroads for making fragrances, agrochemicals, and plastics. That synthetic shampoo scent? Isobutyl chloride might be somewhere in the production chain. The plastics in car parts and packaging often begin with simple building blocks like this one. Reviewing patents or material safety data sheets for household products, I’ve noticed this one pop up in the background, quietly enabling the supply chain to run smoothly. The formula matters because it keeps everyone on the same technical page, whether that’s procurement, production, or regulation.

Toward Better Communication and Safer Handling

Industry benefits when everyone from technicians to engineers communicates using the same chemical names and formulas. Standardized, science-based approaches build trust. C4H9Cl isn’t a random code—it tells you the molecular skeleton, signals the need for certain protective gear, and fits into the legal frameworks built to protect both workers and communities.

Anyone working around chemicals—whether in a lab, a plant, or handling logistics—owes it to themselves and others to memorize, double-check, and respect chemical formulas. That single letter or number makes a real-world impact on safety, efficiency, and compliance. Getting those details right stands as one of the most practical skills in the technical world.

Understanding Isobutyl Chloride

Walk through any chemical plant, and someone will bring up isobutyl chloride. Transparent with a sharp smell, this liquid finds its way into many industrial formulas, especially when making solvents or pharmaceuticals. The odd thing is, plenty of workers have handled it and not everyone knows what makes this compound so risky.

Health Concerns and Real-World Risks

Most people who work with isobutyl chloride spot the signs quickly: harsh fumes, skin that tingles, eyes that tear up. Inhaling its vapors for even a short period can lead to coughing and headaches. If skin or eyes come in direct contact, redness and burning usually follow. Chronic exposure goes deeper, causing damage to the nervous system, respiratory irritation, and sometimes even liver trouble. According to data from the Centers for Disease Control and Prevention (CDC), high exposure can bring about faintness or difficulty breathing—a serious issue in confined spaces.

During my time in a warehouse that stocked industrial chemicals, strict rules applied to storing and handling substances like isobutyl chloride. A single spilled drum meant immediate evacuation, not because of panic, but because the compound’s toxic fumes build up fast indoors. You can’t just open a window and shrug it off.

Why Everyday Experience Matters

One thing often forgotten: personal experience shapes how people understand risk. Reading about toxicity on a label feels worlds apart from the sting when a splash of isobutyl chloride lands near your face shield. I saw a mechanic burn his hand once when a glove had thinned out; the result was a visit to urgent care and a stern safety briefing for everyone. These stories carry more weight than any technical bulletin.

Pathways to Safer Interaction

Workplaces that use isobutyl chloride rely on well-established protective measures for good reason. Ventilation, chemical-resistant gloves, and goggles aren’t suggestions—they save trips to the hospital. The National Institute for Occupational Safety and Health (NIOSH) lists this substance as hazardous and recommends air monitoring and spill control. Every label and safety data sheet drills home the importance of storing it away from heat, open flames, and sources of moisture, since it can produce noxious gases if it catches fire or reacts with water.

Spill kits designed for volatile organics make a difference. In places I’ve worked, these kits sat at the end of every aisle. Managers doubled up with regular safety drills, making sure everyone drilled the steps for a response: cordon off the area, alert the right people, ventilate fast, and never try to mop it up with bare hands.

Possible Solutions Moving Forward

Product designers and chemical engineers keep searching for less toxic alternatives. Some labs have cut out isobutyl chloride from their process entirely by swapping in less hazardous chemicals, even if these switches cost extra time and money. Where replacement isn’t an option, automation cuts down on direct exposure. Simple moves like using closed systems for transfers or fitting splash guards prove invaluable.

Health and safety isn’t a one-off project; it’s a culture. Employers owe it to their staff to explain risks, provide clear instructions, and make equipment available right where it’s needed. For anyone reading safety data about isobutyl chloride, it helps to remember real-world stories and facts: It is hazardous. The right approach—protective gear, good training, and vigilance—keeps accidents out of the headlines.

Understanding the Risks

Working in chemical labs taught me that shortcuts with storage often create bigger problems down the line. Isobutyl chloride doesn’t mess around. This clear, colorless liquid packs a mean punch with its sharp, choking odor. Remember years ago when a leaky drum made everyone evacuate a wing of our plant? Turns out, isobutyl chloride reacts strongly with moisture and flames up with the smallest spark. Ignoring these risks brings property damage, severe burns, and even poisoned lungs. Stories circulate for a reason—carelessness with volatile chemicals leaves scars, both physical and on workplace reputations.

What Real Storage Looks Like

Forget about stacking canisters on any old shelf. Spills and accidental mixing can turn a typical shift into an emergency. I saw too many old-timers use rusting cabinets, thinking the ventilation would save them, but proper chemical storage works only if everything stays dry and away from heat. Containers made of glass or certain plastics hold up best—steel’s out, since corrosion means leaks. Flammable liquid safety cabinets, clearly labeled and grounded, block stray sparks and contain fumes. That bright yellow paint on the cabinets isn’t for decoration—it signals a whole different level of caution.

Why Ventilation Beats Luck

Years back, I learned quickly that fume hoods are worth every penny. I remember pulling samples for a routine test and getting overwhelmed because the bottle sat open longer than needed. Vapors spread quickly. Without proper airflow, a single slip leads to a room that’s unsafe in minutes. Air needs to move out and away from people, not recirculate. Installing fresh air systems or using modern vented cabinets means you don’t rely on luck to keep breathing safely.

Fire Hazards and Emergency Prep

Hot days bring out the worst in volatile chemicals. Isobutyl chloride gives off flammable vapors near room temperature. Leaving it near heat sources, direct sunlight, or electrical panels just courts disaster. I always tell new team members: ground your storage, double-check seals, keep extinguishers close—and make sure those extinguishers work on chemical fires. Basic drills, up-to-date spill kits, and ready-to-go respirators mean the difference between minutes of stress and weeks of cleanup.

Training Makes the Biggest Impact

No engineer or safety manager can walk every aisle all the time. Folks working with isobutyl chloride need hands-on practice with the equipment and an honest understanding of what can go wrong. Education shapes habits. Seeing the old burn marks on metal floors or hearing about someone’s burnt skin sticks with you in ways policy manuals can’t capture. Clear training, practical drills, and honest stories give everyone a deep respect for what they’re handling.

Building Safer Habits—Now, Not Later

Small steps—regularly checking labels, sticking with tested equipment, and not cutting corners during busy stretches—keeps accidents from becoming headlines. Chemicals demand respect every day, not just after near-misses. Facilities putting time, money, and attention into safe storage set their workers up for success. Respecting these lessons and listening to folks who’ve seen things go wrong means you go home healthy at the end of each shift.

Understanding Isobutyl Chloride

Isobutyl chloride pops up in many chemical manufacturing operations. Having spent time working around industrial solvents, I have seen firsthand how easy it can be to overlook risks just because something becomes routine. Isobutyl chloride brings real hazards — it burns eyes, irritates skin, damages lungs, and easily catches fire. Even a brief exposure to its fumes can cause coughing and headaches. Simple carelessness can cost a lot.

Personal Protection Matters

I learned early that no shortcut beats proper protective gear. Gloves, chemical-resistant goggles, and a tight lab coat stand between you and painful chemical burns. Thin nitrile or latex gloves don’t stand up long against isobutyl chloride; only neoprene or specially rated chemical gloves will. Standard safety glasses don’t seal out vapor. Goggles with side shields and a face shield cut down risk. It takes only one small splash to remind you that it’s better to look overdressed than suffer a trip to the emergency room.

Ventilation and Air Quality

Fumes create a hidden danger. Isobutyl chloride vaporizes at room temperature and the smell doesn't always give enough warning. A proper fume hood turns out to be more than a box; it’s a real frontline defense. Cracking a window or running a regular fan won’t do the trick. I have watched coworkers forget this step and complain of nausea or dizziness. Carbon filters and regular airflow checks make a huge difference for everyone involved. Emergency eyewash and shower stations also matter — in an accident, speed and proximity save health.

Safe Handling and Storage

Labeling every bottle or drum avoids mix-ups, but that’s just the start. Isobutyl chloride reacts with water, acids, or strong bases, so good storage keeps it away from anything that could start an unwanted reaction. I never leave it near metal shelves where corrosion can eat through containers over time. Plastic or glass, with well-fitted caps, always feel safer. Every spill — even a small one — warrants immediate cleanup using absorbent pads and a waste drum, not paper towels. Regular housekeeping prevents problems before they begin.

Fire Risks Cannot Be Ignored

Flammable solvents call for strict attention. Sparks, static electricity, and careless cigarette use present real threats. I remember drills at my facility where even ignoring one frayed power cord got flagged. Grounding containers and wearing antistatic clothing are not just red tape — these steps prevent catastrophe. Fire extinguishers rated for chemical fires, not just standard office extinguishers, belong nearby. Having a spill kit ready, with instructions everyone remembers, beats trying to improvise during an emergency.

Health Training Saves Lives

Knowing what to do after exposure closes the safety loop. Too often, I hear, “I’ll just rinse it off” or “it won’t be that bad.” Medical attention after skin or eye contact controls long-term harm. Reporting every incident, no matter how small, helps others learn and improves protocols. Regular training hammers home dangers people start to forget. I trust my coworkers with my safety and never hesitate to speak out if something seems off. Safety becomes habit through honest talk and repetition.

The Real Stakes

An accident with isobutyl chloride doesn’t just cause a temporary headache. It truly threatens sight, skin, and breathing. At stake is not just compliance but real, lasting health. Every minute spent on prevention pays off in peace of mind and safety for everyone on the job.