Ethyl Bromoacetate: A Chemical Commentary

Historical Development

Chemists first synthesized ethyl bromoacetate back in the 19th century, opening an important chapter for synthetic organic chemistry. The early push toward new organohalide compounds stemmed from the search for building blocks that could drive innovation across medicine, agriculture, and even military science. Friedrich Wöhler’s experiments in the mid-1800s showcased that with simple reagents, manufacturers could produce ethyl bromoacetate reliably on a moderate scale. By the early 1900s, production scaled up, as the demand for alkylating agents soared in research and industrial circles.

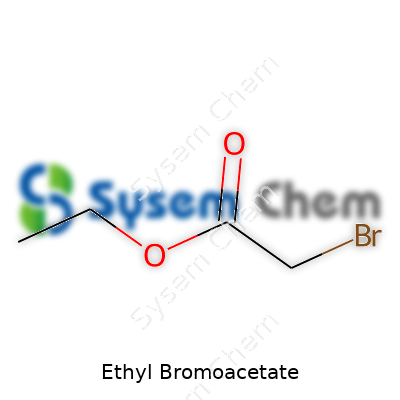

Product Overview

Ethyl bromoacetate remains a staple reagent for any well-stocked chemical laboratory. This compound, with the formula BrCH2COOEt, features a bromo group and an ester group on a two-carbon backbone, offering a unique versatility. Researchers rely on its ready reactivity for crafting new molecules, especially where a convenient bromoethyl group helps stitch together larger frameworks. In my own experience, nothing beats its predictability for alkylation, especially when exploring novel pharmaceuticals in a research setting.

Physical and Chemical Properties

This liquid has a distinctive, penetrating odor, reminiscent of many low-molecular-weight halo-organic esters. At standard conditions, ethyl bromoacetate appears as a clear, colorless or faintly yellow liquid, boasting a boiling point in the neighborhood of 155 °C and a melting point well below room temperature, around -51 °C. It's heavier than water, with a density close to 1.5 g/cm3, and shows limited miscibility in water while proving very soluble in organic solvents like ether and chloroform. Its reactivity comes from the electron-withdrawing bromine, sitting alpha to a carbonyl, which attracts nucleophiles seeking to form new carbon–carbon or carbon–heteroatom bonds.

Technical Specifications & Labeling

Chemical suppliers usually market ethyl bromoacetate with purities above 98%. The packaging reflects its sensitivity: glass bottles, amber for UV protection, and sturdy caps to ensure containment. Standard labeling practices call for clear hazard warnings, including the GHS skull and crossbones for acute toxicity and the exclamation mark for skin and respiratory irritation. Each batch includes an analysis certificate: purity, water content by Karl Fischer titration, and NMR spectra to confirm the absence of diethyl ether or other esters. Every user is reminded of its volatility and the risks that improper storage can pose, as hydrolysis or unintended heating may compromise the product and create safety hazards.

Preparation Method

Lab chemists usually prepare ethyl bromoacetate using a classic reaction between bromoacetic acid and ethanol, catalyzed by strong acid—often sulfuric acid. The protocol starts by carefully mixing cooled bromoacetic acid with ethanol, then adding catalytic acid to speed up esterification. The reaction mixture heats under reflux, sometimes for several hours, to drive completion. Afterward, distillation separates the desired product from side products and unreacted starting material. In industrial settings, companies employ larger glass-lined reactors under strictly controlled conditions to minimize worker exposure and environmental release, keeping yields and safety high.

Chemical Reactions & Modifications

Ethyl bromoacetate behaves as a classic electrophile in alkylation chemistry. Nucleophiles—amines, thiols, alkoxides—readily displace the bromide, forming new bonds that underpin key pharmaceutical scaffolds or specialty chemicals. In my work, I witnessed its efficiency during glycine ester synthesis and quaternization of heterocycles. Chemists often explore modifications by substituting the ethoxy group or introducing various nucleophiles, developing a slew of analogs for drug testing or agrochemical research. Besides straightforward substitutions, the ester group itself serves as a platform for reductions, hydrolysis, or even transesterification, broadening its uses further.

Synonyms & Product Names

Ethyl bromoacetate goes by several labels in commercial and academic literature: bromoacetic acid ethyl ester, ethyl 2-bromoacetate, EBA, or ethyl bromomonoacetate. You’ll spot it on laboratory shelves worldwide, sometimes cataloged by major chemical suppliers under these names, allowing easier cross-referencing in scientific research. Like most chemicals of its class, these synonyms can matter a great deal during procurement, as confusion here often leads to costly errors, supply delays, or mislabelling.

Safety & Operational Standards

Workplace safety with ethyl bromoacetate remains non-negotiable for any lab or plant. This reagent poses considerable hazards: strong skin and eye irritant, significant inhalation hazard, and the potential for severe lung and organ damage upon prolonged exposure. Strict personal protective equipment (PPE) is a must: gloves, goggles, fume hoods, and lab coats stand between the chemist and serious risk. Spill protocols call for rapid evacuation, appropriate absorbent, and safe disposal using proper solvent waste procedures. Down the line, international agencies such as OSHA and the European Chemicals Agency demand documentation, safety data sheets (SDS), and ongoing training for anyone handling or transporting this reagent. In my experience, even a brief lapse—say, setting aside PPE during cleanup—can lead to minor or major incidents.

Application Area

Across academia and industry, ethyl bromoacetate acts as a linchpin for innovation. Organic synthesis groups use it to construct α-amino esters, malonate derivatives, and heterocycles, which serve as the backbones for pharmaceuticals and crop protection agents. Materials scientists often rely on its unique reactivity to build specialty molecules for dye chemistry or polymer studies. For those in medicinal chemistry, the bromo group’s leaving ability means short, reliable routes to key building blocks, especially in developing anti-cancer or anti-bacterial candidates. Professors still assign it in practical organic labs, keen for their students to master both its handling and its scope.

Research & Development

Research around ethyl bromoacetate rarely stands still. Top organic synthesis teams search for greener, safer ways to accomplish alkylation, hoping to reduce hazardous byproducts and energy use. Newer catalytic systems—think phase-transfer catalysts or ionic liquids—are starting to displace traditional, more wasteful techniques. Analytical chemists have started mapping its distribution and environmental persistence, sparking a wave of studies into better containment and remediation. In collaboration with industry, academic groups often tailor analogs to meet rising regulatory demands: lower toxicity, faster breakdown, and improved yields, particularly for pharmaceutical intermediates. Efforts around continuous flow synthesis look promising, especially for pushing down both waste and human exposure.

Toxicity Research

Researchers long ago identified ethyl bromoacetate as acutely toxic. Inhalation, skin contact, or swallowing brings rapid onset of symptoms, including central nervous system depression, breathing difficulties, and corrosive damage to organs. Repeated low-level exposure still poses chronic health risks, such as liver or kidney impairment. Studies with animal models show potent mutagenic or carcinogenic tendencies, fueling ongoing reviews of permissible exposure limits. Regulatory bodies keep tightening the screws on occupational exposure, calling for even stronger engineering controls and medical surveillance. Safety benchmarks have pushed many chemists to seek safer substitutes for some applications, or to reinforce their lab’s ventilation, monitoring, and emergency response protocols. Despite all this, the scientific community still requires further toxicokinetic studies, particularly in the area of environmental persistence and downstream metabolite identification.

Future Prospects

Looking ahead, several trends will likely shape the future of ethyl bromoacetate. Regulation keeps bearing down on hazardous chemicals, driving both manufacturers and research teams to rethink traditional synthesis routes. Innovation in green chemistry, such as biocatalysis, and benign-by-design reagents seems poised to address the health and environmental impact associated with organobromides. Startups and major chemical suppliers alike view this not as an inconvenience but as a chance to spark novel techniques—lower waste, higher atom economy, and tighter controls on emissions. Pharmaceutical companies now weigh environmental costs alongside synthetic efficiency, which can shift priorities away from halogenated reagents unless absolutely essential. Many chemistry departments invest in awareness campaigns and new training modules, aiming to keep personnel prepared for handling substances like ethyl bromoacetate safely. Meanwhile, ongoing reformulation and alternative development may slowly push classic reagents toward niche status, while nimble new approaches step in to fill the gap for future science and industry.

Understanding Its Place in Chemical Synthesis

Anyone working in organic chemistry soon finds out about ethyl bromoacetate. This compound doesn’t turn up in blockbuster movies or household products, but walk into a research lab or a university course, and you’ll bump into it before long. Ethyl bromoacetate belongs in the toolbox for building more complicated molecules. Its main trick comes from the combination of an ester and a reactive bromo group, which makes it almost like a double agent—it brings two useful handles for chemists to grab onto in a single molecule.

Making New Medicines and Crop Protectants

Drug discovery projects often lean on ethyl bromoacetate early in the journey, not in the final pill, but in the pieces chemists need to build to get there. Alkylation reactions—essential for fusing carbon parts together—become easier because this compound hands over its bromo group quite willingly, allowing other molecules to hook on in its place. That forms new carbon bonds, which is a big deal in drug design.

Outside of medicine, companies in agriculture put this tool to use, too. Making herbicides and insecticides often relies on the same kind of carbon backbone-building that pharmaceutical labs chase every day. Over the years, several commercial compounds protecting crops have needed a step involving ethyl bromoacetate as a key ingredient. Real-world experience in a process lab showed me that if you want reliability, you stick with chemistry that works. Chemists keep ethyl bromoacetate around for just that reason.

Education and Teaching Real Reactions

My first hands-on lesson with ethyl bromoacetate came in a university classroom. It showed up during a discussion of the malonic ester synthesis—one of those classic reactions students use to learn how to stretch or twist small chemicals into bigger ones. Everyone wore gloves, used good ventilation, and paid extra attention. This chemical gets respect. It’s a strong alkylating agent, which means it reacts with all sorts of things, including people if you’re not careful.

Teachers pick it for demonstrations because it truly illustrates core principles in organic synthesis. Once, a sharp classmate asked why we couldn’t use something safer or milder. The answer from our professor—who never sugarcoated risks—was clear: certain structures just can’t be made as effectively with anything else. Ethyl bromoacetate delivers a unique combination of reactivity and versatility at a price that makes sense in education.

Handling Hazards and Improving Safety

Every lab regular—student or professional—knows ethyl bromoacetate demands real precautions. Its vapors irritate the eyes and lungs, and spills call for a fast cleanup under the strictest protocols. I remember a couple of tense moments with a leaky container: gloves, splash goggles, chemical hood, the works—the right equipment kept everyone safe.

Calls for safer alternatives are growing as research progresses. Some labs experiment with different reagents or look for less volatile options, but so far, most substitutes fall short in performance. Until then, strong training and better equipment keep people safe while getting the chemical results needed for discovery.

Moving Research Forward

Every bit of progress in materials, medicines, or farming relies on tools that get the job done. Ethyl bromoacetate may not make headlines, but in the hands of trained chemists, it moves science ahead—carefully, thoughtfully, and with respect for both its strengths and its dangers.

Why Ethyl Bromoacetate Needs Caution

Ethyl bromoacetate pops up in college chemistry labs, research centers, and sometimes even in small-scale manufacturing. It’s a strong alkylating agent, known for how quickly it reacts with proteins, DNA, and other molecules. This kind of reactivity brings both usefulness and risk. I remember watching someone develop a rash just from a small spill on their glove. Once you see up close how quickly problems develop, you start treating chemicals like ethyl bromoacetate with serious care.

Direct Health Hazards

Exposing your skin or eyes to this compound can cause burning, blisters, and long-term irritation. Inhaling its vapors leads to coughing and, sometimes, lung damage. The bromo component poses its own risk—chemicals with bromine tend to act as strong irritants and can have delayed health effects.

One year in grad school, a bottle cracked during a midday rush. Even a small amount made the space fill with an acrid smell that forced a full evacuation. Later, everyone felt tightness in their chest, despite only brief exposure. That experience pushed most of us to check our fume hoods more carefully, every single time.

Proper Personal Protection

Lab coats and safety goggles don’t always cut it. For ethyl bromoacetate, splash-resistant gloves (like nitrile or butyl) matter, and a proper face shield adds another layer against accidents. Using a double glove gives an extra few seconds to react if a spill happens.

Along with gloves and shields, thin plastic aprons protect your lower body and shoes should fully cover your feet. I learned to appreciate disposable sleeves the day a drop hit my wrist beneath a loose cuff—one oversight is all it takes.

Keeping the Air Clean

Work always happens in a chemical fume hood—never at an open bench. Ethyl bromoacetate vaporizes fast, and even tiny spills can fill a room with dangerous fumes. I’ve seen what happens when hoods malfunction. It’s not worth the risk of trusting just a cracked window or tiny fan; professional fume extraction isn’t optional with volatile compounds like this one.

Emergency Moves

Spills need action right away. Absorb with spill pads, not loose paper or rags. For bigger emergencies, powder absorbents or sand contain the liquids. Every lab I’ve worked in keeps calcium gluconate gel on hand for accidental contact, along with eyewash stations and showers clean from debris and clutter.

Hospitals can help with short-term symptoms, but fast action on-site often keeps things from getting worse. Once, a quick rinse at the eyewash station saved a colleague from permanent vision problems.

Storage Smarts

Store ethyl bromoacetate in glass containers with chemical-resistant stoppers, never metal. Keep away from sunlight and heat sources. Secure cabinets marked for toxins prevent casual access. Familiarity breeds carelessness, but mixing up bottles or misreading a label carries a big risk with this compound.

Building a Safer Habit

In every lab where safety rules get taken seriously, you see fewer accidents. Regular drills, clear emergency plans, and personal accountability help catch sloppy habits before they turn into serious events. People make mistakes, but showing respect for powerful chemicals keeps everyone in the room safer.

Why Ethyl Bromoacetate Matters in Laboratories

Ethyl bromoacetate connects deeply with anyone who has set foot in a research lab. Having worked with a variety of reagents in organic synthesis, I always keep an eye on compounds that add both simplicity and usefulness. Ethyl bromoacetate has that appeal. When you see that formula C4H7BrO2 pop up, you can almost smell the faint hint of sweet solvent in the air, knowing that both reactivity and caution go hand in hand. The molecular weight clocks in at 167.00 g/mol, which is instantly memorized by chemists juggling reactions.

The Science—And the Story

Organic chemistry often turns into a grind of endless reactions and purifications. Ethyl bromoacetate bucks that trend. With a straightforward structure—a two-carbon ethyl group, a bromo substituent hugging a methylene, and an acetate—this molecule feels intuitive to break down. The bromine acts as a leaving group, practically inviting nucleophiles to attack. That quality makes ethyl bromoacetate a favorite alkylating agent; I’ve seen it used countless times to add a simple ester group or to chain together carbon backbones that serve as stepping-stones in drug synthesis or even fragrances.

Learning about chemicals like this in academic settings doesn’t always translate to appreciating their impact. In industry, speed and reliability dominate. This molecule fits well—quick reactions, few side products, and a manageable hazard profile outweigh flashy digital catalogs. Real lab experience shows that a trusted chemical can save time troubleshooting and give more reproducible results.

Addressing Hazards in Practical Work

Hazards stick out for ethyl bromoacetate. No one forgets the warning about lachrymators after just one whiff. Anecdotally, the burning eyes and strong scent stick in your memory. That runs parallel to what safety data will tell you—skin, eyes, and lungs don’t like contact, so gloves, fume hoods, and goggles become as important as the chemical itself. Mishandling leads to downtime, and that affects both research momentum and budget.

I’ve seen teams rush to the emergency shower plenty of times. Beyond personal stories, incidents involving improper storage, open bottles, or poor labeling make their way into lab folklore, serving as reminders. Setting up safety audits and periodic training usually improves compliance better than just a binder full of rules.

The Bigger Picture: Availability and Sustainability

Ethyl bromoacetate remains widely available across chemical suppliers worldwide, which keeps costs stable and access straightforward. Sourcing chemicals used to mean flipping through thick catalogs; now, digital platforms speed up procurement, but the fundamentals matter just as much. Any junior researcher should understand the pros and cons before ordering by the kilo.

With growing focus on greener chemistry, it’s also fair to consider where wasted bromoacetate ends up. Waste collection for halogenated organics often costs more and calls for real attention. Encouraging methods that recover or neutralize bromine residues helps both compliance and the environment. Industry continues to evolve, and staying up to date with greener alternatives and better disposal makes a real difference.

Not Your Everyday Chemical

Ethyl Bromoacetate might sound like just another chemical name, tucked away in some warehouse, but the reality of its storage says a lot about both responsibility and safety in the workplace. Coming from a background in hands-on laboratory and process management, I’ve seen what can go wrong when folks underestimate a substance because they don’t see immediate risk. It’s clear that a chemical like ethyl bromoacetate, known for its volatility and toxicity, is not something to leave to chance or weak protocol.

Understanding the Risks

This liquid packs more punch than its clear appearance suggests. Ethyl bromoacetate can irritate the skin, eyes, and respiratory system. Working with this stuff even in a controlled lab, I remember just a tiny spill left my gloves tingling. The fumes can sneak up, causing headaches or worse if you don’t have proper ventilation. The fire danger is just as real — it’s flammable and reacts dangerously with many common materials including strong acids, bases, and metals.

The Real Deal About Storage

So, let’s skip past generic advice. A basic locked cupboard doesn’t cut it. Ethyl bromoacetate belongs in a specific flammables cabinet, built to resist fire and prevent leaks. I’ve always made a habit of storing volatile chemicals well below eye level—less splash risk in case of a dropped bottle. This also helps avoid fumbling with heavy containers, reducing accidents. One important tip: make sure the storage area isn’t near acids, bases, cyanides, or anything remotely reactive, since unexpected combinations can turn a plain shelf into a disaster.

Big point here—temperature matters. Ethyl bromoacetate does better kept cool. It shouldn’t freeze, but room temperature in a climate-controlled locker works. Hot stockrooms or exposure to direct sunlight make the vapors more aggressive and risky. All bottles need tight, chemical-resistant stoppers: no jury-rigging with plastic wrap or makeshift lids.

Keeping People Safe

From experience, PPE stations close to the storage room make a difference. Respirators, chemical splash goggles, and gloves (nitrile works well against organics) should be an arm’s reach away. Posting visible hazard communication labels with pictograms and first-aid instructions helps new staff—even the most experienced can have an off day and forget which bottle is which.

Reducing Environmental Impact

Some folks forget about spill trays. These trays catch drips or leaks and make for simple clean-ups. I still remember a day when a cracked bottle leaked overnight, and the spill tray was the only thing standing between us and an expensive, hazardous cleanup job. For ventilation, chemical storerooms fitted with exhaust fans ensure that if anything goes wrong, the fumes don’t linger and build up unseen. Good air exchange saves lungs and prevents explosive environments. Storing chemicals in secondary containers also gives an extra layer of defense, slashing the odds of a big spill if the main bottle fails.

Staff Training: The Missing Link

I’ve been through enough staff rotations to know training often gets cut first, but that’s asking for trouble. Regular refreshers, clear signage, and hands-on drills beat a stack of unread safety manuals every time. Anyone with access to ethyl bromoacetate must know the risks, the procedure for grabbing it safely, and how to handle spills or accidents. By making training an everyday thing, rather than a checkbox on an HR form, it keeps everyone sharp and ready.

Wrapping Up with Common Sense

In my experience, it all comes down to treating chemicals with a mix of respect and skepticism. Trusting labels and routine isn’t enough. By building habits around safe storage, clear labeling, and proactive training, workplaces avoid both injuries and those panic-inducing close calls. Ethyl bromoacetate demands this approach—not just for compliance, but because lives and the environment are both on the line.

What Is Ethyl Bromoacetate?

Ethyl bromoacetate stands out as a chemical compound with a strong smell and an oily nature. From the outside, it might not look much different from other clear liquids used in synthesis labs. Its role in organic chemistry often involves serving as a building block for pharmaceuticals, flavors, and dyes. Even though it has a place in research and industry, this is one of those liquids best kept at arm’s length.

The Trouble with Handling Ethyl Bromoacetate

Anyone working in a chemistry lab learns early on to treat certain chemicals with extra caution—ethyl bromoacetate falls neatly in that category. My own experience tells me that even seasoned researchers pay this substance respect. Skin irritation starts almost immediately upon contact, and breathing vapors makes your nose and throat burn. It’s not just about discomfort; the threat goes deeper.

Inhalation, ingestion, or skin contact can do real harm. Poison control centers flag ethyl bromoacetate for its toxic effects. Swallowing even small quantities often leads to nausea, vomiting, stomach pain, and in more serious cases, damage to internal organs. Breathing significant amounts can bring about chest tightness and coughing fits; extended exposure sometimes lands people in the emergency room.

Why the Risks Demand Attention

The main worry centers on ethyl bromoacetate’s ability to penetrate the skin and enter the body quickly. Some cases document secondary poisoning because vapors hang heavily in poorly ventilated spaces. People tasked with disposing of chemical waste or cleaning spills often report numb fingers and headaches. Hearing those stories makes you double-check your gloves and tighten your respirator straps.

Long-term exposure remains a topic that safety teams never brush aside. There’s evidence linking ongoing contact to nerve and liver damage. Animal studies reinforce the message: repeated low-level exposure can disrupt blood chemistry and slow down reaction times. The studies highlight patterns all too familiar in labs with loose safety rules.

Fact-Based Precautions for Smaller and Larger Labs

Ethyl bromoacetate’s hazards haven’t escaped the notice of safety agencies. The National Institute for Occupational Safety and Health (NIOSH) and the U.S. Environmental Protection Agency both highlight the importance of preventing overexposure. In my time teaching lab safety, I’ve stressed these lessons with real-life examples. Splash goggles, chemical-resistant gloves, and solid ventilation go beyond just checking boxes—they protect health.

Waste management can’t take shortcuts either. Neutralization procedures stop harm from spreading. Fume hoods, spill kits, and storage cabinets built to resist corrosion make up the backbone of responsible handling. Teams often run drills on what to do during a spill, since panic only multiplies risk.

Steps toward Safer Workplaces

Some groups push for greener alternatives that don’t risk such immediate harm. Advances in chemical engineering hint at substitutes for certain lab protocols, which would leave less room for accidents. Training and firm rules deliver most of the safety improvements in today’s facilities. From firsthand experience, nothing replaces a clear set of instructions and a watchful supervisor. Mistakes with ethyl bromoacetate rarely go unnoticed, so the drive for smarter, safer labs continues nonstop.