Cyclopentyl Chloride: The Backbone of Many Chemical Pathways

Historical Development

Cyclopentyl chloride has a story that mirrors the rise of organic chemistry in the last century. Researchers started paying attention to chlorinated cycloalkanes back in the days of the burgeoning plastics and pesticide industries. Curiosity about reaction intermediates led early chemists to cyclopentyl chloride, as they explored how basic chemical building blocks could be tweaked with relative ease through halogenation. In my own digging through literature, I noticed journals from the 1940s hinting at its role in synthetic projects, using old-school glassware setups and basic distillation. These early papers mark cyclopentyl chloride as a chemical workhorse, quietly moving from academic interest into commercial production once its value in producing flavors, pharmaceuticals, and specialty materials became clear.

Product Overview

Cyclopentyl chloride stands as a classic organic intermediate with the formula C5H9Cl. People in chemistry circles use it because its reactive chlorinated ring opens doors to further modifications—a crucial step for anyone interested in creating specific flavors, scents, or building blocks for drug development. Seeing barrels of the stuff in a specialty chemical warehouse, I realized just how integrated it has become for companies aiming to build complex molecules from simple, accessible starting points.

Physical & Chemical Properties

Pouring cyclopentyl chloride into a beaker gives a colorless to pale yellow liquid with a biting aroma that won’t let you forget its presence. It evaporates without much fuss at room temperature, thanks to a boiling point around 104-106°C. Lower density compared to water means it floats, but be prepared for its limited solubility in water—this matters a lot in waste handling and cleanup work. I learned firsthand that it dissolves easily in organic solvents such as ether or acetone, so cleanup and extraction never take too long. The chlorine atom on the ring imparts reactivity without being explosively unstable, making it approachable for those who know how to show it some respect.

Technical Specifications & Labeling

Suppliers typically bring cyclopentyl chloride to market at purities north of 98%, ensuring most users get material with low moisture content and minimal by-products. Containers bear hazard pictograms warning of flammability, acute toxicity, and environmental risks, as dictated by GHS and OSHA standards. My own experience handling it meant double-checking labels for its UN1267 shipping code and the “Warning: Lacrimatory” marking. Tracking lot numbers and sourcing documents often gets overlooked, but batch consistency matters for anyone doing sensitive organic syntheses or regulatory submissions.

Preparation Method

Laboratories and factories rely on one dominant approach: the chlorination of cyclopentanol using reagents like thionyl chloride, phosphorus trichloride, or phosphorus pentachloride. The process feels straightforward for chemists, but a full-scale plant run turns into a delicate balance of temperature control, vapor handling, and proper ventilation. I remember a hood full of off-gassing SO2 reminding us not to cut corners. This direct substitution method stands out for its yield and predictability, letting manufacturers scale up without giving up on quality.

Chemical Reactions & Modifications

Drop cyclopentyl chloride into the hands of a skillful chemist and it becomes a gateway to new molecules. The molecule serves as an alkylating agent in Grignard reactions, opening the ring to broader transformations. Nucleophilic substitution lets it turn into amines, ethers, or thiols, depending on the nucleophile and conditions chosen. In a few projects I took part in, this reactivity helped craft intermediates for pesticides and custom pharmaceuticals. Strong bases can pull off eliminations, and those products sometimes act as flavor ingredients or specialty solvents. Flexible, reactive, and seldom fussy, it offers synthetic routes most other five-carbon rings can’t.

Synonyms & Product Names

Walk through catalogs and you’ll encounter cyclopentyl chloride listed under trade names like chlorocyclopentane, cyclopentane chloride, or even cyclopentyl monochloride. Regulatory documents or safety data sheets may use these terms interchangeably, so newcomers sometimes end up double-checking CAS numbers—1678-71-9 in most cases. Staying familiar with different naming conventions keeps ordering and communication headaches to a minimum, particularly in multinational supply chains or regulatory audits.

Safety & Operational Standards

Handling cyclopentyl chloride means putting safety first, every single time. Its volatility and toxicity require solid engineering controls—exhaust hoods and explosion-proof storage cabinets are not optional. Personal experience taught me to never underestimate glove degradation, since repeated exposure can sneak up. Respiratory protection often becomes part of the workflow to guard against inhalation. Training staff on spill response and chemical burns matters more than paperwork; I’ve seen a splash handled calm and fast thanks to readiness. Waste runs through neutralization and incineration streams under strict oversight, keeping it from the water table or air.

Application Area

Companies rely on cyclopentyl chloride for building more complicated organic compounds—think big pharma, agrochemicals, or fragrance houses. It often plays a supporting role in making specialty resins, drug intermediates, and even new taste and aroma compounds. Over the years, I’ve watched smaller contract labs turn barrels of cyclopentyl chloride into pilot batches of patented molecules that pave the way for everything from crop protection agents to rare flavor ingredients found in chewing gum. Its versatility invites ongoing discovery across the board, wherever reactive rings and selective alkylations turn raw ideas into marketable material.

Research & Development

Academic and industrial labs have kept cyclopentyl chloride in focus for its role as a model in ring substitution chemistry, catalysis, and stereoselective synthesis. Published research continues pushing boundaries—one project I followed built out fluorinated analogs for better drug absorption, while another explored the use of less hazardous reagents in its synthesis to limit environmental impact. More recent innovation looks at pathways for greener chlorination and ways to recover and reuse process solvents. These advances help companies claim lower emissions and safer workplaces, with an eye on environmental and workplace regulations tightening everywhere.

Toxicity Research

Cyclopentyl chloride presents real hazards if handled carelessly. Direct contact irritates skin and eyes, while inhalation leads to respiratory distress and neurological symptoms. Repeated exposure in animal studies has flagged central nervous system effects and mild liver changes, which underscores the need for thorough risk management. Toxicological databases and regulatory guidelines keep updating with new data, driven by ongoing studies of breakdown products and chronic exposure risks. My own respect for the material deepened after seeing in vitro tests link reactive metabolites to cellular changes. For workers and the environment, strict controls limit accidental release and ensure safe end-of-life disposal.

Future Prospects

Demand for cyclopentyl chloride keeps shifting as industries adapt and new chemistries come online. Regulation and corporate green goals have started steering production toward less hazardous feedstocks, better recycling, and minimized by-products. Market expansion in pharmaceuticals and agriculture continues, especially where creative chemists see new uses for its five-membered chlorinated core. I sense future refinements will focus on selective synthesis, minimizing waste, and aligning with tightening health standards in global markets. Those conversations between chemists, safety officers, and regulators shape the future of cyclopentyl chloride in a world that values both performance and responsibility.

Understanding Cyclopentyl Chloride in Real Lab Life

Walk into any bustling organic chemistry lab, and you might come across a clear liquid with a distinctive scent, labeled “cyclopentyl chloride.” On the surface, it just sounds like another tongue-twisting chemical. Dig a bit deeper, and this compound reveals a lot about how the world of chemical synthesis works behind the scenes. Cyclopentyl chloride rarely goes straight into finished products that you’d touch, taste, or see directly. Instead, it’s the unsung building block behind some everyday goods and the specialized chemicals that keep industry rolling.

Starting Point for Bigger Chemicals

Ask a chemist what they do with cyclopentyl chloride, and the answer usually involves building something more complex. Cyclopentyl chloride acts as a solid starting material in creating pharmaceutical intermediates—these are the in-between steps on the route to a pill or treatment. Because its cyclopentyl ring (the five-carbon loop) holds its shape under rough reaction conditions, it serves as a reliable foundation when synthesizing more intricate molecules.

I’ve seen it pulled off the shelf to make custom-made chemicals for drug discovery. Chemists often connect it to other fragments—usually by swapping out the chlorine atom—for something that bonds tightly with the ring, like an amine or an alcohol group. This forms new compounds with properties that researchers want, such as anti-inflammatory activity or improved absorption in the body.

Route into Agrochemicals and Fragrances

Cyclopentyl chloride doesn’t just help medicine; it’s also involved in making chemicals that go into pesticides and herbicides. In agriculture, new molecules often get tested for safety and effectiveness against pests, and cyclopentyl chloride helps chemists experiment by serving as a useful starting point.

Some flavor and fragrance companies also use it as a building block. By reshaping its core cyclopentane structure through a series of chemical reactions, they get new aroma molecules that find their way into perfumes or household products.

The Risks and the Rules

Like many organic chlorides, cyclopentyl chloride demands respect in the lab. Its fumes irritate eyes and lungs. Safety protocols—solid ventilation, gloves, goggles—can’t get skipped. I remember one safety training where a colleague described a mishap: a cracked container released enough vapor to cause a coughing fit, driving home how easily overlooked hazards lead to trouble. Chemical companies can’t just ship and use it without following rules set by environmental and occupational safety authorities. They keep close tabs on waste management and exposure.

Rethinking the Environmental Impact

Manufacturing chlorinated compounds raises concerns about what happens when they exit the plant. Cyclopentyl chloride can produce hazardous byproducts if it’s not managed correctly—things like hydrochloric acid or more persistent chlorinated wastes. That’s why companies look for tighter controls and safer alternatives whenever possible. Development teams seek routes that reduce the use of potentially harmful starting materials or improve capture and treatment after use.

Smart Solutions Going Forward

Green chemistry is changing how cyclopentyl chloride gets used. Process chemists experiment with greener solvents, closed reaction systems, and better recycling in the lab. On the regulatory side, companies track emissions more closely and invest in technology to clean up what leaves the production site. In research, people are testing chlorine-free alternatives in hopes of making pharmaceutical and agrochemical manufacturing cleaner from the start.

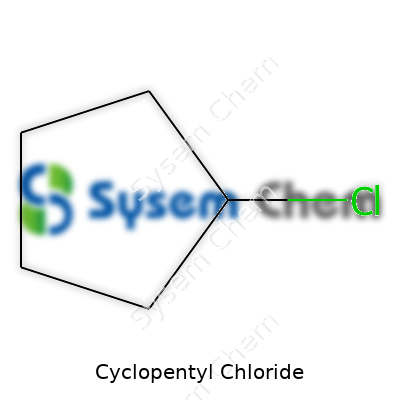

Structure and Formula

Chemistry class doesn’t always prepare you for putting molecule shapes into something practical. With cyclopentyl chloride, it helps to visualize the carbon ring first. This compound features a five-carbon ring—cyclopentane—with one hydrogen replaced by a chlorine atom. You build the formula by counting up the usual hydrogens, subtracting one for chlorine’s presence, and slotting chlorine into its spot. The molecular formula comes out as C5H9Cl.

Real-World Use and Impact

Chemical professionals rely on knowing accurate formulas for safe handling. Cyclopentyl chloride’s formula isn’t trivia. In the lab, using the right amount keeps reactions in check. Get the numbers wrong, and you risk more than just a bad yield—you can end up with toxic fumes or unpredictable side effects. Personal lab experience pushes this home. Working with halogenated compounds always put an extra emphasis on calculation, since missed details can turn a straightforward experiment into a hazard.

Safety Considerations

This compound’s chlorine atom packs more punch than its carbon and hydrogen cousins. Chlorinated organics often trigger tighter safety protocols. Ventilation, chemical-resistant gloves, and goggles become routine. Industry guidelines, like those from OSHA and the CDC, stress handling compounds with chlorine with special care, since inhalation or skin exposure brings risks that simple hydrocarbons don’t carry. My time in research labs showed that familiarity breeds carelessness—many accidents begin with “I’ve done this before.” Clear formulas help spot dosing errors and prevent repeat mistakes.

Sourcing Accurate Data

Reliable information protects both the experiment and the experimenter. Textbooks and safety sheets align on the formula C5H9Cl, but it’s never wise to rely on memory alone. Publications like Merck Index, along with chemical supplier catalogs, serve as valuable backup. In my experience, keeping a physical or digital folder of up-to-date chemical data sheets avoids confusion—especially when managing stockrooms or setting up undergraduate chemistry labs. Google Scholar and reputable journals back up textbook data, and double-checking against PubChem or Sigma-Aldrich listings gives peace of mind.

Common Problems and Solutions

Mix-ups tend to happen with cyclopentyl chloride and its close relatives—like cyclopentane, cyclopentanol, or other halo-cyclopentane derivatives. Attention to chemical names guards against simple but costly errors. Label everything, stick with standard nomenclature, and keep molecular formulas posted right on storage bottles. Teaching assistants and researchers benefit from color-coded charts showing formulas for frequent reagents, making mix-ups less likely in busy prep rooms.

Improving Chemical Awareness

Public awareness about chemicals in our everyday lives remains low. Most people walk by industrial facilities with little sense of what’s inside those barrels and tanks. Understanding the formula for something like cyclopentyl chloride goes beyond academic interest—it links to real conversations about chemical safety, environmental regulations, and basic health questions. In my neighborhood, community science nights gave parents and students a chance to see formulas in action, linking classroom chemistry to the products stashed under their sinks. Experiences like these bridge the gap between textbook facts and meaningful understanding.

Building Trust Through Expertise

Sharing accurate, practical information on cyclopentyl chloride means drawing from both formal education and hands-on laboratory work. Trust builds over years of experience, mistakes, and face-to-face teaching. Consistent fact-checking, clear labeling, and ongoing training prevent problems before they start—steps every lab and classroom can take, no matter the budget.

Risks Hidden in the Drum

Most folks who step into a chemical supply room know the faint sting of solvents or the sharp note that signals something more serious. Cyclopentyl chloride, with its colorless look, often doesn’t draw much attention—yet its fumes pack both a punch and a risk. The stuff can irritate eyes and the lungs, and even skin contact triggers a burning sensation. For a long time, I watched new lab workers treat containers of this chemical as if they held nothing more than water, at least until someone near an open bottle coughed or their glove started to feel warm from a splash. Proper storage stops those accidents before they even begin.

Ventilation’s Quiet Power

Any storage area worth its reputation moves air quickly and efficiently. Cyclopentyl chloride evaporates fast and fills enclosed spaces with toxic vapor if it sits unchecked. A friend of mine once ended up in the emergency room after an exhaust fan failed in our old storage space. Ever since, I always double-check the air system is humming before shelving another drum or bottle. Chemical storage isn’t just about shelving and labels—making sure vapors keep moving goes a long way in keeping people healthy over the years.

Keep Cool, Stay Safe

Heat and chemicals do not mix well. Cyclopentyl chloride should never rest near any kind of heat source—radiators, space heaters, even direct sunlight streaming through a dusty window. Store it away from electrical panels and don’t let the temperature climb high. Most experienced warehouse managers keep chemicals like this somewhere cool and dark. Years ago, an unexpected summer heat wave nearly turned an unventilated storage shed into a disaster zone, causing a bottle to crack and leak. Since then, temperature checks on hot days are as important as locking the door.

Separate to Avoid Surprises

I once saw a small explosion in a lab that mixed incompatible chemicals. Cyclopentyl chloride reacts badly with strong oxidizing agents—think bleach or nitric acid. Separate shelves or even different rooms keep this and other reactive chemicals well apart. No one wants a spill from the next shelf over to trigger a fire or worse. Smart labeling, bright hazard signs, and a clear plan for shelving cut out confusion, even if someone new rotates into the team.

Labeling and Documentation Matter More Than You Think

I’ve worked with labs where the labels wore off or homemade codes replaced full names and warnings. Cyclopentyl chloride demands clear, tough labels that don’t fade or peel, listing not just the name but the hazards and last inspection date. A central log helps staff know what sits where, which batch might be getting old, and if any containers look compromised. Relying on memory alone fails, especially after a few long weeks or a shift change.

Simple Steps Pay Off

Safety showers, spill kits, chemical-resistant gloves—these tools all matter, but making sure cyclopentyl chloride stays in a well-ventilated, cool, secure space, far from heat and incompatible substances, offers the strongest protection for everyone working near it. Daily habits, not just training sessions, keep serious mishaps away. No one wakes up wanting a trip to the hospital or a call to emergency services. Small investments in proper storage mean workers get home safe every night and chemicals do their job, not more.

Understanding the Risks

Cyclopentyl chloride isn’t found around the average house, but anyone who works with chemicals in a lab or plant setting likely crosses paths with it. Exposure can burn skin, irritate the eyes, hurt lungs and nose, or even trigger headaches and dizziness if you breathe in the vapors. Over time, spills, poor ventilation, and slipping on a carelessly cleaned floor pile on risks most folks don’t see coming. No one wants to end up in the ER because of a moment’s distraction.

Practical Safety Steps

Experience has shown that the basics of chemical safety never lose relevance. Working with cyclopentyl chloride, you want to start by putting on solid protection. Splash-proof goggles keep eyes safe, tight nitrile or neoprene gloves keep the substance off your skin, and a lab coat or chemical apron guards clothes and the rest of your body. When running a fume hood, it helps pull harmful vapors up and away before they can cause trouble.

Chemical labels don't cover every real-world scenario. In practice, it makes sense to set up a dedicated spot for weighing, pouring, and transferring cyclopentyl chloride. A clear workspace means you won’t bump containers or knock something over while reading or chatting, so stray spills happen less often. Always double-check that bottles have screw caps or secure seals to keep them from leaking during storage or after use.

Ventilation and Storage

Getting fresh air in and keeping fumes from building up matters. Old labs with cracked windows often cause a false sense of security. Running the right exhaust fans or hoods cuts down exposure quickly. I once worked in a place where an overstuffed fume hood let clouds of fumes slip back into the room. We fixed the problem by keeping containers small and never letting the hood crowd up with clutter.

Storing cyclopentyl chloride in a dry, cool spot keeps bottles from swelling or leaking. Putting containers in a chemical storage cabinet, away from direct sunlight or any reactive chemicals, always makes a difference. I’ve seen people toss incompatible chemicals on the same shelf, leading to emergencies that could’ve been avoided. Use clear labels and make sure the date opened stays on the bottle.

Response Plans Matter

Even with good habits, spills still happen. Spill kits, plenty of absorbent pads, and emergency eyewash stations should never collect dust. Make sure every worker knows how to use them—not just the lab supervisor. Practice goes further than a printed list taped up on the wall.

If exposure does happen, fast action matters. Rinsing eyes or skin with running water for several minutes, removing contaminated clothing, and heading straight to a health professional ends up saving a lot of anguish later. Training everyone in basic first aid, rather than just sending out memos, builds trust and gives confidence during real emergencies.

Building a Safety Culture

Every workplace sets its own tone about safety. Old habits, shortcuts, or ignoring a near-miss only increase the odds of trouble next time. Open talk, regular training sessions, and honest reporting of every incident help people stay alert. I once saw a seasoned chemist fix a problem on his own, then explain to the team what happened. That transparency goes a long way in building a culture where everyone looks out for each other.

Purity Grades: Real-World Choices Matter

Cyclopentyl chloride might look just like another colorless liquid, but things get complicated as soon as you start asking about purity. In a real lab, the grade stamped on the drum makes a huge difference. Years ago, walking through a chemical storeroom at a university, I saw students ignoring the fine print on bottles. One bottle labeled “technical” grade, another “analytical”—not interchangeable. Taking shortcuts with purity almost always costs more in wasted time, poor yields, and safety risks.

Lab Bench to Industry: Why Purity Changes Everything

Most people don’t realize how much rides on a decimal point in purity. Low-purity cyclopentyl chloride works in industrial applications where cost trumps precision. Road salt has more dirt in it than table salt. For processes like large-scale polymer production, a few percent of impurities won’t sink the project. Refineries and bulk chemical plants often choose technical grade cyclopentyl chloride because the cheaper price matters more than ultra-clean composition.

Move the scene to pharmaceuticals or electronics, and suddenly anything less than high purity can spell disaster. Drug reactions depend on reliable, trace-specific interactions. If the chloride isn’t pure enough, side reactions jump in, and toxic byproducts can form. In my experience working alongside organic chemists, we tracked down yield problems to nothing more exciting than a supplier who switched batches without warning. Switching from 98% to 95% can introduce enough water, acids, or unreacted precursors to change the outcome.

Quality Checks and False Economy

Lab supply companies often sell the same chemical in two or three grades. The differences are in price, testing, and the paperwork. High-purity or analytical grade cyclopentyl chloride comes with certificates showing not just quantity, but exactly which impurities are in the mix. Tech grade lacks that precision—or sometimes the paperwork entirely. Factories buying technical grade often build in extra filtration steps as insurance, since they can't afford downtime or ruined batches.

A common mistake: trying to save money by switching to technical grade in a sensitive process. I’ve seen entire batches go down the drain when a trace impurity, undetected in the rush, ruined the product. It’s tempting to cut corners, but pure chemicals protect workers, processes, and the bottom line. Product recalls, regulatory violations, and liability lawsuits can outweigh any savings from bargain-grade chemicals.

Improving Access to Reliable Grades

Getting the right purity isn’t just a matter of spending more—it’s about asking questions and verifying what you really need. Too often, buyers accept a quote without reviewing test reports or calling suppliers about their quality control. A robust purchasing process means requesting batch analyses, questioning vendors about testing, and sometimes paying a premium for certainty.

Education also matters. Lab managers and purchasing agents benefit by attending workshops on chemical quality standards. Bringing everyone onto the same page about what those small differences mean for safety and success helps prevent costly mistakes.

Staying Safe and Productive

Access to different purity grades reflects both the complexity and the flexibility of modern chemistry. Skipping the conversation about quality opens the door for problems down the production line. Backed by experience and plenty of trial and error, I’ve learned that investing time upfront to match grade to purpose remains the best way to protect people, equipment, and research.