Bromoform: Life, Science, and Risks Woven Through Chemistry

Historical Development

Chemistry has always carried a bit of adventure. In the 1820s, Jean-Baptiste Dumas and Auguste Cahours hit upon bromoform while tinkering with the family of haloforms. At first, it didn't make much noise, sandwiched between its cousins chloroform and iodoform, but over time, bromoform built its own profile. Back then, folks leaned on trial and error, and health and safety took a back seat to curiosity. Hospitals and doctors tried bromoform in cough syrups and sedatives. These early days shaped the guidelines modern chemists now live by, where careful testing and respect for risk matter as much as discovery. As science moved beyond the gaslight era, bromoform stepped out of the pharmacy cabinet and into research and specialty industries.

Product Overview

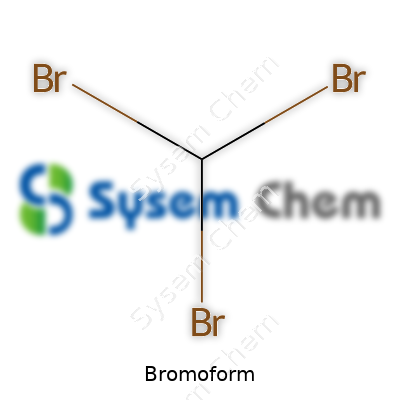

Bromoform is a dense liquid with a distinct, sweet odor. Many know it from its chemical formula, CHBr3. Once packaged in dark glass bottles, today it ships in steel drums or polymer containers built to keep air and sunlight away. Labs and chemical warehouses keep it on hand for the occasional synthesis or environmental test. It looks almost like water but carries a heaviness in both feel and risk, used in industry and marine research way more than on pharmacy shelves.

Physical & Chemical Properties

The first thing most people notice about bromoform is its heaviness; a spoonful outweighs an equal measure of water due to its density of 2.89 g/cm³. The liquid pours clear and colorless, turns floors slick, and gives off a strong, almost sickly sweet smell. It boils at just under 150°C, which means open flames or heat sources spell trouble. Solvents like alcohol and ether dissolve it easily. In water, it lingers but does not mix, often forming a separate layer. Bromoform’s structure–a single carbon bonded to three bromine atoms and one hydrogen–makes it both reactive and tricky. It speeds up certain alkylation reactions and, like chloroform, fits in heavy liquid separation thanks to its density. If spilled, it evaporates but leaves a dangerous vapor.

Technical Specifications & Labeling

Regulators and quality auditors do not cut corners with bromoform. The stuff comes labeled with UN numbers, hazard symbols, and carefully documented chemical purity, usually 98% or higher for most lab uses. Labels warn of environmental toxicity, harmful vapor, and risk to skin or eyes. Certified labs must run purity checks by gas chromatography. Material Safety Data Sheets need to ride with each batch. These standards matter, not just for compliance, but because even a splash or breath can set off trouble in a workroom or storage area.

Preparation Method

Old textbooks describe the classic route: adding bromine to ethanol or acetone under alkaline conditions. Sodium hypochlorite or sodium hydroxide get the reaction going, then the batch gets heated gently to drive off bromoform as a heavier layer. Extraction takes a practiced hand and care not to breathe the fumes. Today, the approach uses closed reactors with good ventilation, with electronic monitors watching over temperature and pressure. Temperatures go no higher than needed to avoid runaway reactions or vapor loss. Technicians skim the bromoform off, dry it, and wash away base and leftover reactants. Post-processing steps scrub traces of water and impurities before the compound heads for packaging.

Chemical Reactions & Modifications

Chemists learned quickly that bromoform is both an end and a stepping-stone. The compound reacts easily under strong base, producing dibromocarbene, a highly reactive intermediate that can chew up double bonds or insert into aromatic rings. Bromoform finds use in the Haloform Reaction, a classic test for methyl ketones. Sometimes, researchers dehalogenate bromoform, stripping off bromine to build smaller, more complex molecules. In marine chemistry, bromoform functions as a tracer because it sticks out in gas chromatography. In the hands of a skilled synthetic chemist, its three bromine atoms offer leverage in the design of heavy organic molecules or radiolabeled compounds.

Synonyms & Product Names

On the shelf, bromoform passes by names such as tribromomethane, methane tribromide, and methyl tribromide. Catalogs from Sigma-Aldrich, Fisher Scientific, and Merck list it under CAS number 75-25-2, or simply “Bromoform, ACS Reagent Grade” for research work. Each name signals a heritage dating back centuries, crisscrossed through different languages, patent claims, and regulatory codes.

Safety & Operational Standards

Handling bromoform calls for discipline and respect. Eye protection, chemical gloves, and well-fitted fume hoods come standard. The vapor can irritate lungs and central nervous systems, leading to dizziness, nausea, or worse if exposure goes untreated. Legislation across Europe and North America locks down on storage, with strict limits on atmospheric release and runoff. Emergency eyewash stations and spill kits answer for sudden accidents. If skin contact happens, it needs swift washing with soap and water. Handling protocols benefit from regular drills and up-to-date hazard training; complacency finds no room. In my own time working basic undergraduate labs, the most memorable lesson came from a professor who made students read both the history and the toxicology before ever opening a bottle. Good habits minted in the safety lab stick for life.

Application Area

Once popular as a sedative and cough suppressant, bromoform's days in pharmacy have faded. Marine researchers value bromoform as a marker in studies of oceanic halocarbons, tracing underwater volcanic vent activity and plankton chemical signals. Some geologists use its dense liquid character to separate heavy minerals in rock samples for academic work or mining analysis. In specialty organic synthesis, the compound steps in to build brominated intermediates for dyes and pharmaceuticals. Analytical labs test drinking water for trace residues, especially near industrial discharge points. Agriculture keeps a close eye on bromoform output from certain seaweeds, since naturally occurring emissions impact ozone chemistry and air quality.

Research & Development

Curiosity keeps bromoform in active rotation in both academic and government labs. Researchers dig into its formation in seawater, where sunlight, bromide ions, and algae catalyze natural emissions. Some studies target bromoform breakdown products, searching for clues about air quality and greenhouse gas dynamics. Others focus on green synthesis: tweaking preparation to cut back on toxic byproducts or energy use. Industrial teams work on containment and reuse, experimenting with closed-loop systems to reduce spills and emissions. Patent filings surface every year, charting ways to harness bromoform’s reactivity for specialty polymers or selective catalysts. Universities use bromoform’s physical features to teach phase separation, density, and classical reactions, keeping foundational memories alive for the next crop of scientists.

Toxicity Research

Bromoform sits high on the watchlist for chemical hazards. Direct animal testing from the past shows damage to liver, heart, kidneys, and nervous system. Hydrolysis produces bromide ions, which carry risks of their own, affecting thyroid function if chronically exposed. Inhalation or oral intake leave acute effects: headaches, nausea, even unconsciousness where doses rise high enough. Regulators set exposure limits low; OSHA and EPA both list the compound as a probable human carcinogen, and the International Agency for Research on Cancer flags it based on animal data. Drinking water standards clamp bromoform down to microgram-per-liter levels, with constant research on detection and removal. Environmental safety teams check effluent and groundwater, wary of long-term build-up.

Future Prospects

Tech keeps pushing the value and risk profile of bromoform in both directions. Green chemistry tries to steer its production toward safer, lower-impact processes with clever catalysts and recovery units. Environmental science leans on improved sensors to watch for spills or atmospheric drift. More labs experiment with biological pathways, asking if enzymes from marine algae can provide a milder, more sustainable route. In the regulatory arena, policymakers update labeling and worker exposure standards, chasing down gaps left from years before. As climate science zeros in on trace gases, bromoform’s fingerprint in ocean-atmosphere chemistry pulls in grant money and new collaborations. Lessons learned from two centuries of trial and error keep modern handlers cautious, yet determined to wring new insights from an old, heavy molecule with plenty of stories yet to tell.

Bromoform: A Chemical with a Foot in Many Worlds

Bromoform shows up as a colorless liquid with a sweet-ish odor, and it’s heavier than water. It’s one of those chemicals that sounds like it might only matter in a lab, but people actually use it in some pretty surprising ways. If you’ve ever wondered how certain science experiments work, how the livestock industry tackles environmental issues, or why old chemical textbooks keep mentioning this stuff, there’s a story behind it.

Bromoform’s Place in Research

Most chemistry classrooms keep bromoform on a short leash, mainly due to its density. It helps separate minerals based on how heavy they are. Drop a piece of mineral in bromoform and you can see pretty quickly if it sinks or floats. Geologists and gemologists appreciate this test because it’s simple, and it works. Sometimes, the world of gem identification pulls bromoform out for the kind of straightforward mineral testing that gets results without high-tech machinery.

New Attention: Methane and Cattle

Farming looks a lot different than it did fifty years ago, and bromoform now finds itself at the center of a newer shift. One of the surprises hiding in seaweed is a small dose of bromoform. Researchers noticed that cows who eat certain types of seaweed burp out less methane—a gas that traps a lot of heat in the atmosphere. Red seaweed, especially a variety called Asparagopsis, carries bromoform. It blocks an enzyme in the digestive systems of cattle that usually leads to methane gas. That means farmers looking to reduce their greenhouse gas output pay attention to seaweed-based feed additives.

A study out of Australia showed that cows fed a small amount of red seaweed reduced their methane emissions by up to 80%. That’s no small leap, considering livestock gas accounts for a good chunk of farm-related pollution. So this chemical, hiding in seaweed, could help fight climate change by cutting the amount of methane hitting the air. It’s not on every farm yet. Some worry about the safety of bromoform in animal feed, and more testing is going on to make sure nobody winds up with bromoform in the milk or meat. Still, this area of study keeps pulling in researchers and startups looking for ways to make farming both profitable and sustainable.

Health Risks and Environmental Limits

Before it started showing up in environmental research, bromoform held a place as a solvent and flame retardant. Times change though, and now safety comes front and center. Health experts don’t like people breathing or drinking even small amounts for long stretches. The chemical can irritate skin and lungs, and in higher exposures, it acts as a potential carcinogen. That’s why water treatment plants and factories now watch for bromoform in wastewater and air emissions. Government agencies set limits and monitor water sources. In the U.S., the Environmental Protection Agency lists bromoform among the “disinfection byproducts” that need tracking in drinking water, often forming when chlorine hits organic matter.

Weighing the Trade-Offs

People need balance—a way to harness the power of bromoform without hurting health or the environment. That pushes researchers and regulators to test safety levels in food, keep tabs on water systems, and push companies to look for safer substitutes. From my own fieldwork in rural communities, I’ve seen folks start asking more questions about what ends up in their food and water. More transparency and regular independent testing help build trust and shower some sunlight on chemicals like bromoform. Solutions will keep changing as new science rolls in, but staying alert and asking questions—those habits keep everyone safer.

Getting a Grip on Bromoform's Risks

Bromoform's name doesn’t ring many bells outside certain labs. Folks working with chemicals often bump into it in research, environmental testing, or drug development. The stuff looks like a heavy clear liquid, but don’t let the plain appearance fool you. Bromoform packs a punch when it comes to safety risks. I've spent years poking around chemistry labs, and every time bromoform was hauled out, everybody paid close attention. Slipping up with this chemical can land you in some deep trouble.

Health Hazards Lurk in Small Bottles

Open a bottle of bromoform in a small room, and the sweet, chloroform-like smell might hit you right away—that’s not a good sign. The lungs, the skin, the eyes—bromoform can irritate all of them. Inhaling its vapors sometimes feels mild at first, but there’s evidence it messes with the central nervous system. Nausea, dizziness, headaches, and in higher exposures, even unconsciousness creep up fast. The International Agency for Research on Cancer tags it as a possible carcinogen. I’ve watched an experienced chemist fumble and get a splash on his skin. He felt burning, and the spot stayed red for days. That’s all from brief contact.

No Room for Carelessness

Plenty of errors come from routine. In places where safety goggles and gloves should always come out, sometimes people get lazy. But bromoform isn’t chlorine bleach—it’s more hazardous. Swallow some by accident, even a teaspoon, and you’re risking real poisonings. Livers get damaged, kidneys take a hit, and breathing can slow. There aren’t any home remedies for that. My own habit now is to keep nitrile gloves handy and always check the fume hood’s airflow before opening any halogenated liquid.

Environmental Danger

Tossing bromoform down the drain or letting it evaporate on the bench only spreads contamination further. It doesn’t break down easily. Traces stick around in water and soil, potentially harming fish and other wildlife. Tests show even small concentrations can make aquatic creatures sick. Responsible disposal costs money and takes planning, but skipping steps just moves the risk elsewhere.

Protecting Workers and Labs

Big research groups or commercial labs can limit bromoform exposure with ventilation, glove protocols, and regular safety audits. Most institutions now require chemical fume hoods and closed handling systems. From what I’ve seen, the tightest controls work best: smaller bottles, splash goggles, double-gloving, lab coats, and warning signs keep mistakes in check.

The job doesn’t end there. Keeping good training in place means less complacency. New students and staff get thorough briefings, not just quick checklists. It pays to explain exactly why nobody wants a bromoform accident on their watch. Sharing near-miss stories keeps dangers real, not abstract.

Looking Beyond Bromoform

Some scientists want to swap out bromoform in field testing and chemical synthesis, especially where safer options exist. It takes extra time and money to find and verify replacements, so change drags on. But seeing the hazards up close makes you care less about convenience and more about safety. Bromoform has its uses, but treating it as just another liquid means asking for trouble. Using every safeguard, from air filtration to smart training, gives everyone a better chance to walk away healthy at the end of the day.

Getting to Know Bromoform

Bromoform shows up as a colorless to slightly yellow liquid, heavy enough that it sinks in water instead of floating. Pouring a sample in the lab, you notice its sweet, almost medicine-like smell. This sharp odor is pretty noticeable and reminds those handling it to pay attention to proper ventilation. Reports from chemists confirm that long exposure to its vapors can cause headaches or dizziness, showing that safety matters just as much as curiosity in science.

Physical Properties Put to Use

A standout trait of bromoform is its density—almost three times heavier than water. This makes it useful in mineralogy for separating minerals based on how they float or sink. Unlike oil floating on water, bromoform forms a layer at the bottom, making these applications straightforward. Its boiling point hits 149°C, meaning it won’t evaporate from open containers at room temperature as quickly as other volatile chemicals.

Crystal-clear in pure form, bromoform sometimes takes on a yellow tint if left open or in sunlight, hinting at its tendency to decompose. Its solubility in water is low, but mix it with alcohol, ether, or chloroform, and you get a uniform solution with no separation lines.

Chemical Characteristics Shape Its Role

Bromoform holds steady under mild conditions—an asset when storing or handling it. In contact with strong bases or with sunlight, it breaks down, giving off toxic fumes that create a pungent, irritating cloud. At home in the halomethane group, its carbon atom links to three bromine atoms and one hydrogen, sharing a molecular structure with related chemicals like chloroform.

I've seen bromoform’s chemical properties come into play during undergraduate organic chemistry experiments. Its triple bromine bond lends it fire retardant qualities and also presents risks, forming harmful byproducts if not treated carefully. Experienced chemists keep their procedures tight, aware of the environmental persistence and bioaccumulation potential bromoform brings to the table.

Impact on Environment and People

Working in a research lab with bromoform, protecting skin and lungs becomes second nature. LD50 values point to moderate toxicity—more than enough to demand respect but still manageable with basic protective gear. Spills aren’t just a hassle; they can seep into soil or waterways, lingering for years and posing risks to aquatic life. Unlike some chemicals, bromoform doesn’t break down quickly on its own.

Public health experts continue to watch water supplies since trace amounts sometimes show up after water treatment processes. Bromoform’s chemistry means it forms as a byproduct when disinfectants hit bromide-rich water—connecting industrial chemistry to the glass of water on the kitchen table.

Solutions and Ways Forward

Many labs and industries are already switching out heavier halogenated solvents like bromoform for less worrisome alternatives. Where alternative chemicals don’t match up, tighter fume hood protocols and better waste management can take the risk down a notch. I’ve found that clear labeling and routine training do more to protect teams than any high-tech detector.

It’s not just about following laws—responsible stewardship means understanding how bromoform behaves, where it goes after use, and how its unique chemical properties shape not only laboratory experiments but the environment and the everyday lives of people who will never see the inside of a chemistry lab.

Understanding What Bromoform Is

Bromoform, a liquid chemical with a sweetish smell, doesn’t end up in the same conversations as aspirin or table salt. Used in labs for its density, and sometimes for research around methane reduction in animals, this stuff isn’t something you find at the corner pharmacy. People sometimes stumble onto stories about seaweed, ranching, and bromoform, asking where to get it. That question isn’t as straightforward as it seems.

Why Bromoform Isn’t on Regular Store Shelves

I remember my college days, poking around the storeroom shelves in chemistry class. Most of us didn’t pay much attention to obscure bottles unless a lab called for it. Bromoform drew a warning from my lab instructor. The reason is clear—touching or inhaling this substance is risky. It’s labeled as hazardous. Long-term and short-term exposure might mess with your breathing or nervous system, so it’s regulated in most countries.

Anyone trying to buy bromoform will run into a wall of paperwork. Unlike buying a cleaning product, the process involves a lot of checks—supplier vetting, proof of professional or research need, and proper licensing. This keeps chemicals out of the hands of those who don't recognize the risk or don't have clear, lawful reasons to use them. Suppliers face tough regulations for good reason. Bromoform also pops up as a byproduct in some confined pools or industrial systems, so authorities treat its movement with care.

Where Laboratories and Companies Source Bromoform

Suppliers catering to research labs carry bromoform, though they don’t hand it out to just anyone. Companies like Sigma-Aldrich, Fisher Scientific, and TCI America sell small quantities for legitimate science. Here’s the catch—you’ll need verified credentials. If you call up to place an order as an individual without lab affiliation or a chemical license, you won’t get far. The process might even involve site inspections and storage checks. Transport isn’t simple, either, as the packaging carries its own rules and risks.

Why This Caution Matters

Experience from chemical stockroom jobs, reading labels and Material Safety Data Sheets, taught me caution isn’t just bureaucracy—there have been accidents. The public doesn’t always realize how quickly an innocent-looking substance can cause pain or harm. Regulating sales of bromoform protects people, communities, and the environment from mishaps or worse—malicious use. In labs, bromoform requires a fume hood, gloves, eye shields, and secure storage. These aren't just suggestions—ignoring them puts health at risk.

Is There a Safer Alternative?

Researchers ask about bromoform for density separation or methane reduction studies. Before placing an order, check if new methods or safer chemicals can do the job. Scientific advances sometimes render earlier methods less critical. Resourceful researchers collaborate or borrow small amounts through partnerships with licensed organizations. If you’re part of a legitimate project, reaching out to universities or professional labs could help. For the public, curiosity is natural, but handling chemicals like this best remains in expert hands.

What Makes Bromoform a Challenge in the Lab and Beyond

Bromoform shows up in labs and industrial spaces as a heavy, colorless liquid that gets plenty of attention for its high density and volatility. Many remember their first encounter with that sweet, burning smell that signals it's more than just a chemical curiosity. Its ability to irritate eyes and skin leaves a mark—literally and figuratively. The real risk comes from inhaling its vapors or splashing it on skin. For folks working with bromoform, that memory of headaches or nausea after a careless moment sparks a lifelong respect for storing and disposing of hazardous chemicals.

How Storage Choices Keep People and Workspaces Safer

Not everyone understands how easily bromoform evaporates. At room temperature, it moves invisibly into the air, making fume hoods the safest place to open a container. A sturdy, tightly sealed bottle made from glass – clearly labeled – shields workers and the building itself from accidental release. You'll find it stashed in chemical storage cabinets rated for hazardous organics, away from oxidizers, acids, or sunlight. Every lab tech knows shelves matter, but it often takes an accident to learn that bromoform tips over far easier than water. Secondary containment trays catch leaks most times and prevent a minor spill from turning into a major headache.

Local regulations matter just as much as best practices handed down over years. Safety Data Sheets (SDS) for bromoform spell out the no-nonsense facts: keep it cool, dry, and well-ventilated. There’s no room for shortcuts, and seasoned chemists pass down stories about “just a little heat” ruining entire batches or setting off alarms.

Disposal Can’t Wait: Why the Drain Won’t Do

Disposing of bromoform by pouring it down the drain may have happened decades ago, but environmental rules—and plain common sense—don’t allow it anymore. Bromoform doesn’t break down easily. It makes its way into water, lingers, and affects aquatic life. Even small amounts cause headaches for wastewater treatment plants. For folks who care about the environment, knowing their chemical waste isn’t showing up downstream brings peace of mind.

Hazardous waste firms collect and incinerate it at high temperatures. Workers who pack bottles for disposal take time taping lids, wrapping bottles, and noting everything on hazardous waste manifests. Disposal costs run high, so minimizing leftovers keeps budgets healthy. Cleanup kits with absorbent pads and activated carbon cut the risks of spill emergencies. Labs run waste audits to track leftovers and teach younger scientists not to order more than needed.

What Works: Simple Steps for Real-World Safety

Working with bromoform presses everyone to plan ahead, from ordering to final disposal. Every step—cool, dark storage, secure secondary containment, clear labeling—pays off by keeping people healthy and regulations off your back. Regular checks on containers catch leaks before they become problems. Old bottles collect dust in the back of cabinets, so setting reminders to review your chemical inventory every quarter helps remove unsafe leftovers.

At the end of the day, keeping bromoform secure and responsibly handled isn’t about following some faceless rulebook. It’s about the lives behind the lab doors, the water outside the building, and the next generation learning from our habits. Paying attention today saves trouble for years down the line.