Bromobenzene: A Closer Look at a Classic Chemical Compound

Historical Development

Bromobenzene first found its way into laboratories in the 19th century, a period marked by bold experimentation and a hunger for new organic compounds. Back then, chemists relied heavily on coal tar, the motherlode of aromatic compounds. Benzene’s simple ring structure encouraged experimentation, and adding a bromine atom in place of one hydrogen yielded a product with new possibilities. Early researchers noted this new compound’s distinct properties and made it a regular feature in organic synthesis before modern tools like spectrometers even existed. By dissecting aromatic rings with halogens, the early generations set the foundation for much of modern industrial and academic organic chemistry.

Product Overview

Bromobenzene stands as a standard building block for both industrial and laboratory chemists. Easily recognized by its sweet yet faintly irritating smell, this colorless to pale yellow liquid usually comes in glass bottles tightly sealed to prevent leakage. Anyone who has spent time with bromobenzene knows its weight—heavier than water, slow to evaporate, and persistent on lab benches. Chemical suppliers list it both as a solvent and a reagent, recognizing its dual utility. Its simple formula—C6H5Br—makes storage, labeling, and handling straightforward, even under the strict protocols present in modern chemical facilities.

Physical & Chemical Properties

Bromobenzene brings a unique set of characteristics to the table. Its boiling point hovers near 156°C, much higher than benzene itself, thanks to the extra heft of the bromine atom. The compound does not mix easily with water, preferring organic solvents instead. It shines as a non-polar solvent for reactions involving Grignard reagents or lithium exchange—processes where water acts more like an enemy than a friend. Since it resists rapid oxidation and reduction, bromobenzene’s shelf life in chemical storage stretches longer than many similar compounds. I have often noticed in the lab how its density—about 1.5 g/cm³—makes for easy separation in liquid-liquid extractions, a physical property that often saves time and hassle in busy workflows.

Technical Specifications & Labeling

Chemical labels for bromobenzene carry details critical in both safety and accuracy. CAS number 108-86-1 marks its unique chemical identity for databases and shipment tracking, while purity grades range from 98% for general use up to ultra-pure forms for analytical work. Reputable suppliers stamp every bottle with manufacture date, batch number, and hazard pictograms that warn of flammability and environmental risks. Regulatory compliance stamps—REACH, GHS, and local equivalents—provide assurance for storage and usage under even the most watchful safety audits. This extra detail pays off in research labs, where precision goes hand in hand with safety audits and experimental repeatability.

Preparation Method

One common recipe for bromobenzene dates back over a century: treat benzene with bromine using iron powder as a catalyst. The reaction gives a fiery red vapor that demands good ventilation and careful hand. Over the years, chemists adjusted reaction conditions to maximize yield and pare down unwanted byproducts like dibromides. Large-scale production has since moved from open vessels to closed reactors, with automated monitoring to control temperature and excess bromine. In academic settings, this reaction often comes up as an exercise in electrophilic aromatic substitution—a rite of passage for organic students learning the power and pitfalls of aromatic chemistry.

Chemical Reactions & Modifications

Bromobenzene rarely appears at the end of a synthetic pathway. More often, its bromine atom serves as the launchpad for new chemistry. In the hands of a skilled chemist, bromobenzene becomes a precursor to phenols, anilines, or benzoic acids. Transition-metal catalysis—especially coupling reactions like Suzuki and Heck—has turned bromobenzene into the workhorse for introducing complex groups onto aromatic rings. I’ve seen bromobenzene find use in polymer syntheses, as its reactivity bridges the gap between small molecules and long-chain macromolecules. Even with advances in direct functionalization, the selective reactivity of the bromine group continues to justify its widespread buying and selling.

Synonyms & Product Names

While “bromobenzene” reigns as the most common name, bottles might also bear labels such as phenyl bromide or monobromobenzene. Translating documents or navigating supply catalogs uncovers yet more synonyms—bromo-benzene, benzene, bromo-, or even UN 2514 on shipping manifests. These names pop up in patents and regulatory documents, reminding us that language in the chemical world sometimes gets as tangled as the reactions themselves. Researchers searching digital databases should stay alert to avoid missing relevant studies filed under alternate chemical names.

Safety & Operational Standards

Handling bromobenzene demands respect. The compound gives off fumes that irritate eyes and airways, especially in poorly ventilated spaces. Skin contact invites redness and possibly longer-term sensitivity. Labs require fume hoods, gloves, and eye protection—not merely as recommendations, but as necessary safeguards. On top of that, bromobenzene flares up if exposed to open flames or sparks, so strict protocols for storage near flammable chemicals must remain in place. Environmental rules treat bromobenzene as a persistent organic pollutant, requiring careful waste disposal to keep soil and groundwater clean. In large-scale facilities, regular air monitoring and emergency showers stand ready as part of compliance with OSHA, REACH, and local environmental standards.

Application Area

Uses for bromobenzene start in the chemistry lab and spread outward into a range of industries. Pharmaceutical synthesis relies on bromobenzene to introduce phenyl rings into antibiotics and painkillers, while agrochemical makers use it to craft new herbicides and growth regulators. It plays a role as an intermediate in the manufacture of dyes and flame retardants. In the electronics sector, bromobenzene once contributed to the making of certain plastics for circuit boards. During method development, I’ve used bromobenzene as a model compound for testing new techniques in spectroscopy and chromatography—its well-understood properties serving as a benchmark for performance in qualitative and quantitative analysis.

Research & Development

Active research continues to build on the shoulders of knowledge built from bromobenzene. Green chemistry labs press for cleaner synthesis routes that sidestep hazardous catalysts and lower energy inputs, often seeking recyclable iron or solid acid catalysts. Innovation happens on the analytical front, where bromobenzene helps calibrate mass spectrometers during trace residue analysis. In academic circles, attention turns toward asymmetric modifications—methods that make bromobenzene spawn new, chiral compounds for bioactive research. Startups and industrial giants alike scan reaction libraries for schemes that wring more value from the same basic molecule, or ways to reuse bromine byproducts to cut down on waste streams. The compound offers a rich test case, both for basic reactivity studies and for stretching the frontiers of applied catalysis.

Toxicity Research

Bromobenzene carried health warnings long before toxicology matured as a science. Early reports of nausea, headaches, or dizziness from breathing its vapors led safety pioneers to treat this compound with extra care. More recent animal studies sheltered under tighter protocols show liver toxicity and metabolic breakdown products that linger in tissue. Chronic occupational exposure links to a risk of organ damage—reasons enough for labs and factories to take exposure limits seriously. Toxicity research keeps evolving, with modern studies probing its subtle effects at trace doses in aquatic or soil systems. These efforts now help regulators, employers, and scientists improve safeguards and make informed decisions about safe handling both in the workplace and in the environment.

Future Prospects

Bromobenzene’s future remains tied to its versatility and the search for greener alternatives. The pressure toward sustainable chemistry nudges producers to seek renewable feedstocks or recycling options for organobromine compounds. Biocatalysts could someday replace iron or copper in the synthesis, cutting down on heavy metal waste. Regulatory changes on persistent organic pollutants may tighten handling and disposal, pushing even established users to refine their workflows. Automation and robotics create new possibilities for safer dosing and faster reaction profiling, helping large chemical companies and educational labs alike. Recent shifts in research funders’ priorities hint that bromobenzene—like so many mainstay chemicals—must adapt, holding onto its old strengths while adjusting to new demands from science, society, and the environment.

Understanding What Bromobenzene Brings to the Table

Bromobenzene shows up in organic chemistry labs more than most folks realize. I still picture my first encounter with its sharp, almost sweet odor lingering after a late-night synthesis. Its role goes way beyond creating drama on a high school safety sheet. Chemists reach for it because of its versatility. It gives scientists a launchpad for exploring how atoms swap places, and it can be shaped into all sorts of useful compounds.

Tools of Innovation: Making Something Out of a Simple Compound

Anyone tinkering in synthesis might turn bromobenzene into phenol. This transformation means more than just passing an exam. Phenol winds up in antiseptics, plastics, and even the world of aspirin. Take the Grignard reaction: bromobenzene acts as a building block for making new carbon skeletons. Creators in the pharmaceutical world use this path to sculpt drugs with real impact. The same process builds links between materials that turn up in touchscreen gadgets and LEDs.

Engineers and scientists rely on the predictability of bromobenzene. That single bromine sitting on the benzene ring gives it just the right character for reactions, and it avoids sending things wildly off target. I remember using it to introduce just one functional group without making a mess of the rest of the molecule—far easier than working with something too reactive.

Risks in the Real World

Everything has a downside, and bromobenzene asks for respect. Breathing its vapor irritates airways and can pack a punch for the liver if you’re casual with handling it. Plenty of labs slip up on ventilation, thinking that a quick reaction needs no real precautions. From my time running undergraduate labs, I saw too many folks rush, skipping gloves or leaving containers open. The exposure risk is real, and over time, health issues add up in ways students rarely see coming.

Factories making the stuff or burning waste containing bromobenzene often release it into the surrounding air. These emissions don’t magically disappear; they drift and can contaminate water or soil. Wildlife—and people in communities near chemical plants—sometimes pay the price. Tough regulations and smart design help, but enforcement matters just as much as rules. Environmental agencies in the U.S. and Europe keep an eye on it, but big spills and leaks still pop up.

What Can Make a Difference

Education remains the strongest shield in labs and factories. Everyone from seasoned chemists to fresh-faced interns gets safer when training covers real scenarios and not just paperwork. Clear airflow, fume hoods checked every week, and a culture where nobody feels shy about pointing out sloppy habits really cut down on exposures.

Green chemistry brings promise. New research focuses on swapping out halogenated chemicals or building custom processes that leave dangerous leftovers behind. Companies invest in cleaner routes because pressure mounts from regulators and customers who actually pay attention to chemical footprints. Students today have more tools to question old habits and push for safer alternatives, driving long-term change from the ground up.

Bromobenzene keeps its place as a workhorse for researchers, but its story is also a reminder. Progress pairs with responsibility. As new methods arrive, the hope is to keep building what we need—without turning a blind eye to the cost.

The Reality Behind Bromobenzene

Bromobenzene is a chemical that shows up in some unexpected places. It’s part of the toolkit for chemists, who use it as a building block to make other materials. Unlike household cleaners or glue, you don’t see it on store shelves. It turns up in research labs, not in kitchens or garages. That’s a relief in one way, since it keeps bromobenzene away from casual use. Still, this chemical isn’t something you want to handle with bare hands or breathe in without thinking twice.

The Hazards Are Real

Ask anyone who’s worked in a real chemistry lab — safety goggles and gloves aren’t just for show. Bromobenzene carries real risks. The vapor irritates eyes and lungs; you can smell it at low levels, but even a quick whiff can leave your nose tingling. Skin contact triggers redness and dryness. My first encounter with bromobenzene made me glad the lab rules were strict. I didn’t need a second demonstration to know it doesn’t take much to cause trouble.

Beyond short-term effects, long-term or repeat exposure is a bigger worry. Studies show that extended contact may hurt the liver and kidneys. These organs handle a lot of the body’s cleaning work, and chemicals like bromobenzene don’t make their jobs easier. The Environmental Protection Agency lists it as a possible hazard for more than one organ system. Nobody I know is quick to ignore a liver warning label, even if the science still weighs all the risks.

Fire and Spills: Not Minor Issues

Bromobenzene burns easily and makes a thick smoke filled with choking vapors. A spill or an open flame spells a fast-moving mess. Fire departments treat it with extra care. I remember training days where we learned that certain chemicals, this one included, need to be cleaned up fast using special pads and containers. Water alone won’t solve the problem. Firefighting foam comes into play, and nobody wants to see that inside a school or business.

Managing the Risk

Good storage and proper ventilation cut down on danger. In places where people use or store bromobenzene, you see chemical-resistant gear, fume hoods, and clear labels. It’s not just for show; these steps block a lot of the direct exposure and keep the chemical where it belongs. Anyone who works with bromobenzene learns right away that accidents turn serious in a hurry. Training focuses on getting people to react quickly: wash off spills, get fresh air, and call in help instead of hoping things get better on their own.

Alternatives and Best Practices

A few companies and labs now swap bromobenzene for safer ingredients where they can. Green chemistry encourages this move, since every bit less of a hazardous chemical helps. That switch takes effort. Sometimes no good substitute exists. Where bromobenzene remains necessary, the people handling it rely on strict routines and emergency backup. Following guidance from agencies like OSHA protects health, and never skipping a step matters. Many workplaces also set up checklists and double safety signs—small steps that head off bigger troubles.

Hazards only shrink when you respect them. Seen up close, bromobenzene reminds us why safety rules exist and how clear thinking keeps both chemicals and people in their right places.

The Essentials of Bromobenzene

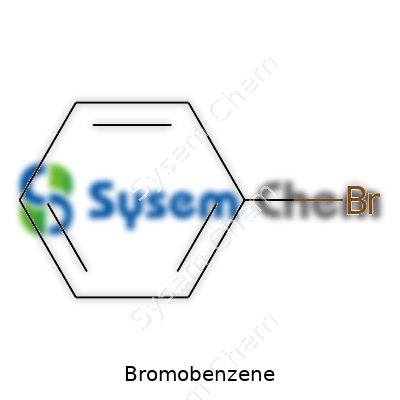

Bromobenzene shows up in a lot of basic chemistry labs and industries. Its chemical formula, C6H5Br, gets straight to the point—one benzene ring with a single bromine atom attached. Plenty of students recognize this formula from textbooks and experiments, and chemists see its uses stretch far beyond the black-and-white lines on paper.

From Classroom to Commercial Labs

I remember mixing chemicals in an undergraduate lab and noticing the smell of bromobenzene cut through the air. Safety goggles fogged up fast. Bromobenzene, despite its rather low profile, commands respect because it’s both simple and surprisingly effective. That C6H5Br arrangement helps scientists kick off a chain reaction of innovation—literally.

Bromobenzene works as a starting point in the synthesis of more complex molecules. Chemical companies use it to produce a range of products: dyes, pharmaceuticals, and flame retardants. Researchers rely on bromobenzene because replacing the bromine atom with other groups opens the door to custom molecules. The Suzuki reaction, which earned a Nobel Prize for its inventors, depends on compounds like bromobenzene to build bigger and more useful organic structures.

Health and Safety: Not to Be Overlooked

Handling chemicals in a lab or factory means accepting real risks. Bromobenzene can irritate skin and eyes. Breathing in the vapors can leave you lightheaded. My own run-ins with volatile organics taught me to trust the material safety data sheets and not to dismiss their warnings. It's one thing to read about health hazards; it's quite another to see a peer sent to the nurse because they overlooked proper gloves.

Chemical hygiene programs, fume hoods, and personal protective equipment make a difference. Clear instructions and steady supervision protect younger students and experienced technicians alike. Authoritative sources such as the Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH) offer detailed exposure limits and highlight the importance of good ventilation. In busy workspaces where speed becomes tempting, returning to these guidelines every day goes a long way.

Solutions and Responsible Practices

No shortcut exists for chemical safety or responsible use. Chemical labels need to stay readable, and outdated stocks should move out of circulation. Labs that keep up regular training sessions see fewer accidents. Chemical waste disposal often gets rushed, but taking those few extra steps avoids bigger problems later on.

For folks in academic settings, programs teaching practical safety skills—well before anyone steps into the lab alone—make a difference. I’ve seen schools invite industrial chemists to discuss real-world mistakes, and those stories make the dangers stick. Shared experiences and honest conversations about errors lead to safer labs and stronger science.

Why Accurate Information Matters

Scientific communities make steady progress because facts matter. Earning trust starts with clear data—chemical formulas, hazard statements, and firsthand accounts. Accurate chemical formulas like C6H5Br don’t just fill exam answers; they ground research, teaching, and industrial production in reliable knowledge. It keeps everyone informed and prepared, and lets the next big discovery rest on a solid foundation.

Getting to Grips With the Risks

Bromobenzene comes up in plenty of chemistry labs and industry workspaces. Once, in an undergrad organic chem class, I watched someone spill a small amount during a rushed transfer—big mistake. The whiff that escaped still rings in my memory. The stuff packs health risks you can't ignore: breathing the vapors leaves you light-headed, and even skin contact leaves behind redness or irritation.

Most folks look at a clear liquid like bromobenzene and figure it won’t do much. The label on the bottle—flammable, harmful if inhaled, irritating—tells a different story. Simple gloves and goggles make a big difference, but not everyone always bothers. One time, rushing between experiments, I skipped the gloves. Just a drop or two landed on my hand, and a burning tingle spread fast. After that, I never skipped the basics.

Solid Steps Toward Safer Practices

Each bottle deserves respect. Good ventilation takes priority—think fume hoods, open windows or at least a solid lab fan pointed outwards. Even one spill can fill a small room with fumes, and a hood isn’t an option for negotiation. I noticed, over years in teaching labs, even experienced researchers get lazy about this step. People talk, get distracted, and forget to turn on the fan. Smart teams keep a note taped to the bench as a reminder. Routines beat memory every time.

Safety data sheets always sit near the chemicals, so any new intern or visitor doesn’t need to search for instructions. Nothing beats a quick check before pouring or weighing. Young researchers get nervous during their first big project, but honestly, most mistakes come from the regulars who let their guard down. Pictograms, hazard ratings—these aren’t just bureaucratic quirks. I learned to read those before I ever touched a bottle. It saved me once during a late-night prep when alarms started chirping from spilled solvent.

Spill kits stay close. Absorbent pads, neutralizers, and gloves—not buried in some basement closet. In my best-run workplaces, we placed these kits under every sink and near lab doors. If something goes wrong, you reach out, grab, and deal with it. No one has time to scramble during an accident.

Storage That Supports Safety

Storing bromobenzene isn’t rocket science, but certain basics matter. The bottle stays well away from heat or sunlight. I remember a chemist who kept a backup stash by the window 'to keep it handy.' All it did was raise the temperature and the odds of a fire. Cool, dark cupboards with secure doors keep everyone safer.

Fire can get out of control fast with solvents like this. One spark from old wiring or a careless match, and the whole stockroom goes up. A grounded flammable cabinet pulls double duty—protection from both accidents and theft. Before I took over as safety lead, our solvents had no lock. After a late-night break-in, we found broken glass—only luck kept the thief from lighting a cigarette nearby.

Tightly screwed caps help prevent evaporation. I remind everyone, new and experienced, to double-check seals before returning any chemical to the shelf. The right labels—clearly printed and dated—keep confusion at bay. More than once, faded or missing labels forced us to toss still-usable bottles just to be safe.

Solutions Built Into Habits

Training new team members takes patience but saves trouble. I run walkthroughs where new hires practice using gloves, reading sheets, and cleaning up fake spills. Open conversations work better than finger-wagging, and a team that shares stories about past near-misses keeps everyone sharp. Chemical safety isn’t just about the latest gear or the rules someone prints out. It’s about building careful habits and looking out for the person next to you.

Why Lab Bench Numbers Matter

In every chemistry lab, some substances show up more often than others, and bromobenzene keeps popping up. For those who have handled it, its faintly sweet smell lingers long after the work is done, and sooner or later, someone asks about its boiling point. On the label, you’ll spot the answer: 156 degrees Celsius. Not much to debate—except the number speaks to much more than a spot on the thermometer.

Handling It Means Knowing It

Lab accidents chip away at confidence fast. I remember watching a new student heat up a flask without checking the boiling points of everything in their setup. The room filled with the sharp tang of burning organics, and it was a quick lesson—lose track of temperature, pay with your nerves or worse.

Bromobenzene doesn’t flash off like acetone. It holds steady until that 156 degree mark. That gives room to work safely, recover or distill it without drama. Anyone handling organic solvents needs this kind of certainty, especially where reactions run hot. The boiling point forms a boundary: cross it, vapors rise, and what starts as a routine task becomes a scramble for containment.

Pure Compounds Build Good Science

Bromobenzene pours clear and colorless, but even small traces of leftover water or old reagents tweak its boiling point. In my early research days, our advisor called us out for reporting “off” values—he’d ask if we’d really cleaned our glassware and dried our solvents. That's not just nagging: lab results need to match the trusted data. For chemists, the boiling point becomes a pass/fail check on purity. If you spot condensation on the flask at 150 or 160, double-check what's in the bottle. Quality work depends on those details.

Risks and Real-World Responsibility

As regulations tighten, the casual pouring and heating of organic solvents doesn't fly. Bromobenzene isn’t some benign guest on the shelf. The United States Environmental Protection Agency lists it as a hazardous air pollutant. Long-term skin contact or inhaling concentrated vapors may bring health problems. Reliable boiling point numbers give safety officers and workers the chance to get things right—ventilation, cooling baths, or distillation setups depend on that trusted figure.

Teaching the Next Generation

Students need more than rote memorization. Anyone training future scientists or technicians should spend time on what these numbers actually mean. It helps to connect the data to the reality of running reactions, minimizing spills, picking the right collection flask, and cleaning up with care. Students should see the boiling point as a checkpoint: ignore it and risk ruined experiments, wasted time, or worse, a trip to the emergency room. Taking that boiling point seriously means taking responsibility for yourself and others.

Moving Toward Better Practices

Information builds safe habits. That magic 156 degrees, confirmed by databases like PubChem and guides like the Merck Index, becomes a daily safeguard in labs worldwide. Students, professors, technicians—they all rely on it to keep processes predictable. Investing a few minutes to verify that boiling point allows better planning.

Bromobenzene doesn’t just ask for respect—it demands it. Reliable data, careful work, and real understanding of properties like its boiling point set the tone for professional, safe, and successful lab work. That number printed in the handbook is more than trivia: it’s a line between order and chaos.