4-Chlorotoluene: A Closer Look at a Key Organic Chemical

Historical Development

Organic chemistry has seen its share of building blocks, and 4-Chlorotoluene, also known as para-chlorotoluene, ranks among those that shaped the growth of the chemical industry through the twentieth century. Early interest stretched back to the expansion of halogenated aromatics, especially as synthetic dyes, pesticides, and pharmaceuticals demanded more specialized intermediates. Back in the days of hand-blown glassware and unreliable temperature control, making chlorinated toluenes required not only skill but a willingness to tackle challenging reactions involving hot, corrosive gases. Over the decades, improved methods and better control over isomeric outcomes lowered costs and lessened the environmental downsides, while regulatory pressures pushed for safer handling—turning what was once a hazardous, niche reagent into a common commodity for medium-scale industry.

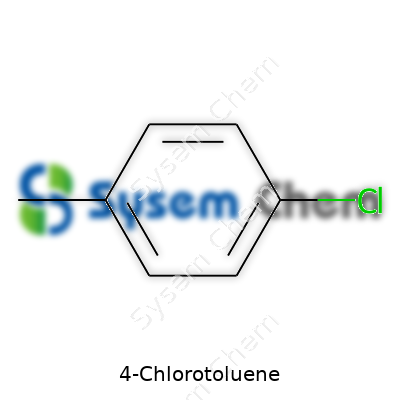

Product Overview

4-Chlorotoluene belongs to the family of chlorinated aromatic hydrocarbons, sporting a benzene ring with a methyl group and a single chlorine atom opposite one another. With that structure, it finds frequent use as a chemical intermediate, stepping into the shoes in the synthesis of dyes, agrochemicals, and active pharmaceutical components. It tends to show up in a clear, colorless liquid form with a sharp, chemical aroma, making it easy to spot. 4-Chlorotoluene often serves as the parent for more complex derivatives, branching out into products that touch everything from inkjet inks to advanced polymers—a testament to the reach of foundation molecules in modern industry.

Physical & Chemical Properties

From a practical standpoint, 4-Chlorotoluene holds its own in the lab and plant thanks to a boiling point around 162°C, which suits high-temperature engineering processes. Its solubility profile makes it a favorite in organic media—it slips effortlessly into ether, alcohol, and most non-polar solvents, but steers clear of dissolving in water. With a density that pushes slightly above water and a vapor pressure that demands well-sealed containers, it calls for a steady hand in storage and transfer. Flammability and a tendency to produce irritating fumes upon combustion put safety high on the list, especially when heat and open flames come into play.

Technical Specifications & Labeling

Producers of 4-Chlorotoluene issue specifications that stretch beyond simple purity—most request assays topping 99%, with tight limits on ortho and meta isomers to ensure process reliability downstream. Water content, acidity, and trace metals round out standard quality checks. On shipping drums and bottles, hazard pictograms and UN numbers highlight its flammable nature and environmental risks. Labs and factories have come to rely on clear, durable labels that survive spills and help workers track important details at a glance. Handling instructions, emergency contacts, and personal protective equipment recommendations now show up as standard features, not afterthoughts.

Preparation Method

Industrial plants mostly churn out 4-Chlorotoluene through directed chlorination of toluene, favoring catalytic routes that push for maximum para-selectivity. Friedel–Crafts alkylation had its day, but lost ground to more efficient chlorination methods that employ iron(III) chloride or similar reagents, which boost yields and keep by-products low. Temperature control and careful feeding of chlorine gas let operators steer the reaction, since too much chlorine can lead to nasty mixtures and waste. Recycling unreacted toluene and fine-tuning quenching steps help firms cut costs and curb emissions, both key to meeting tighter environmental rules.

Chemical Reactions & Modifications

Those in the synthesis game know 4-Chlorotoluene as a true workhorse. It takes part easily in nucleophilic substitution reactions, allowing introduction of amines, nitriles, or alkoxides at the para spot. Oxidation transforms the methyl group to the corresponding carboxylic acid—p-chlorobenzoic acid—used by the ton in polymerization catalysts and esters. Further chlorination or bromination at the aromatic ring enables custom tailoring, while coupling with boronic acids opens doors to biaryl intermediates. Each reaction, carefully tuned, broadens the molecule’s utility and lets chemists spin new products out of the familiar structure.

Synonyms & Product Names

Over the years, 4-Chlorotoluene has popped up under a spread of aliases, including p-Chlorotoluene and 1-Chloro-4-methylbenzene, with registry numbers like CAS 106-43-4 making cataloguing easy. Commercial producers stamp containers with trade names that hint at their internal tracking, but the core identity stays the same. Distributors and buyers working across borders sometimes rely on local language terms, which can lead to mix-ups—so precision in paperwork helps catch errors before they lead to expensive mistakes or missed shipments.

Safety & Operational Standards

Safe handling matters with 4-Chlorotoluene. Labs and manufacturers line up procedures built around closed systems, use of NIOSH-approved respirators during transfer, and strict control of ignition sources. Eye, skin, and respiratory protection get treated as non-negotiables. Emergency protocols for spills highlight containment, ventilation, and use of activated carbon or inert absorbents—no one wants to see this compound in the facility’s wastewater. Fire suppression often calls for foam or dry powder, as water can offer little help besides cooling. Training drills and regular risk reviews build habits that keep workers sharp.

Application Area

Applications draw in a range of industries. Chemical manufacturers plug 4-Chlorotoluene into synthesis chains for agrochemicals, including select herbicides and insecticides that protect crops across the globe. Pigment and dye makers treat it as a staple for key intermediates, especially in the vivid reds and blues that dominate textiles and inks. Some pharmaceuticals count on para-halotoluenes for their early-stage syntheses, where selectivity and reactivity give medicinal chemists room to maneuver. It’s easy to overlook, yet vital in the background of countless consumer goods.

Research & Development

Scientists in academia and the private sector keep finding new directions for 4-Chlorotoluene. High-throughput screening and flow chemistry find ways to make better use of the para-chloro motif, not just as a static group but as a launchpad for libraries of new compounds. Process chemistry teams tinker with greener catalysts, aiming to lower both energy use and by-product formation in bulk chlorination runs. Research also continues into catalytic cycles that skip toxic reagents or use renewable feedstocks, setting the stage for more sustainable operations. It takes a blend of classic skill and modern tech to keep pushing the envelope here.

Toxicity Research

Exposure to 4-Chlorotoluene brings real concerns. Studies highlight its potential to irritate the respiratory system, skin, and eyes, especially with direct contact or inhalation of vapor. Once inside the body, metabolism produces compounds that may strain liver and kidney function, so occupational exposure limits get enforced with teeth. Repeated handling links to nonspecific symptoms like headache and dizziness, steering managers to invest in air monitoring and proper ventilation. Questions about environmental persistence and breakdown products drive fresh studies, especially since aromatic compounds sometimes linger in soil and water. Regulatory agencies keep a close watch, applying lessons from chemical safety incidents of past decades.

Future Prospects

Looking out over the next decade, 4-Chlorotoluene faces both challenges and opportunities. Regulatory reform in Europe and North America pushes for cleaner manufacturing and lower workplace exposures, yet rising demand for fine chemicals in Asia means producers can hardly rest easy. Greener process tech, including biocatalysis and continuous-flow reactors, may lower the barriers between scale, safety, and efficiency. At the same time, new applications in electronics, specialty polymers, and pharmaceutical development—such as designer building blocks for more targeted drugs—hint at staying power for this old workhorse. Those who design safer plants, improve catalytic selectivity, and invest in staff training will set the standard for years ahead.

Digging Into the Uses of 4-Chlorotoluene

4-Chlorotoluene pops up a lot more often than many people realize. The chemical looks like just another clear liquid at first glance, but it has a big job list in manufacturing and industry. The first time I came across 4-Chlorotoluene, I couldn’t pronounce it, let alone understand why anyone would use it. Over the years, I have learned its story overlaps with many items people touch every day.

Fueling Chemistry in Pharmaceuticals

4-Chlorotoluene steps in early when companies cook up certain medicines. Chemists lean on it because its stable ring makes it a solid building block. In the world of pharmaceuticals, minor changes in a molecule can make all the difference. Under those white lab coats, researchers often turn to 4-Chlorotoluene as a starting material for painkillers, antibiotics, and memory-boosting drugs. According to the United States National Library of Medicine, derivatives built from this compound end up improving how some drugs work inside the body. The stability of its chlorinated ring helps keep these medicines safe on shelves, extending their lifetime and guaranteeing the results patients or doctors expect.

Crop Protection and Agrochemicals

Many crops today grow under the watchful eye of chemicals that shield them from bugs and fungi. 4-Chlorotoluene plays a part here, too. Researchers on busy agrochemical benches select it as a core ingredient because its structure attaches well to pesticide molecules. Compounds derived from it help give modern pesticides the strength to fend off pests without breaking down too quickly in rain or sunlight. In 2022, the Food and Agriculture Organization of the United Nations reported that chlorinated intermediates like this one contributed to several new-generation crop protectants. It is like a supporting actor—maybe unglamorous, but without it, the end product just doesn’t do the job.

Powering the Dyes and Pigment Markets

Without strong base chemicals like 4-Chlorotoluene, the colors in textiles, inks, and plastics wouldn’t stick around. Dyes start their journey in giant mixing tanks, where they grab a chlorine atom from compounds like this, locking in vibrant reds, oranges, and yellows. In my own work with a textile supplier, I watched as technicians tweaked small batches of dye, chasing a specific tone that wouldn’t fade after a wash or intense sunlight. Many times, we traced their colorfastness back to the building blocks in the chemical recipe. In fact, ChemEurope cites the importance of chlorotoluene derivatives in maintaining the brightness and durability of industrial pigments.

Industrial Chemistry and Beyond

It doesn’t stop with drugs, crops, and colors. 4-Chlorotoluene finds its way into polymer production and other synthetic materials. Its properties let it become a powerful intermediate for chemical synthesis. The plastics in cars, office chairs, and all sorts of consumer goods frequently carry chemical “DNA” that traces back to its use. In many manufacturing facilities, engineers select it to tweak how flexible or resistant a product feels.

Safety and Environmental Concerns

Companies have an obligation to handle chemicals like 4-Chlorotoluene responsibly. Accidental releases can threaten workers and nearby communities, as well as wildlife. Thankfully, modern factories lean on closed-system reactors and advanced filtration, reducing spills and emissions. Strict regulations shape every step—from transport to storage, as outlined by globally recognized bodies such as the International Chemical Safety Program. These rules draw a clear line to guard the health of both people and the environment.

Looking Ahead

People rely on chemistry to keep our world moving forward, and 4-Chlorotoluene gets called up more often than it gets credit for. Cleaner production techniques and safer handling systems are already making a difference. Investment in green chemistry will drive down risks and create replacement molecules when the world needs less chlorine and more environmental peace of mind.

Understanding 4-Chlorotoluene: More Than Just a Formula

4-Chlorotoluene packs a punch in the world of organic chemistry. Its chemical formula, C7H7Cl, shows a benzene ring holding a methyl group and a chlorine atom. The numbers point to seven carbons, seven hydrogens, and a single chlorine. This shape isn’t random; it guides what the compound can do and how it reacts. If you’ve ever worked in a chemistry lab, you’ve probably come across a bottle labeled with that crisp formula. No matter how small the label, those letters and numbers carry a story—one about structure, function, even safety.

Why Structure Matters Here

Flip through any chemical catalog and you’ll spot many “chloro” and “toluene” names. What sets 4-Chlorotoluene apart comes down to position. The “4” isn’t just a number—it tells you the chlorine sticks to the benzene ring exactly opposite to the methyl group. That distinction shapes more than just a chemist’s sketch. It hits boiling point, solubility, and most importantly, how this compound fits into real-world use.

Chemists rely on these details to make polymers, dyes, agrochemicals, and pharmaceuticals. In my own undergrad years, we drilled deep into the fine lines between isomers. A misplaced chlorine, and your reaction heads in a totally different direction, or your desired product loses its purity. In industry, these mistakes pile up cost and waste, which sharpens the focus on accurate formulas and careful technique.

Why Chemical Formulas Deserve Attention

Getting a formula right isn’t just about passing a quiz. Small differences can mean big consequences, especially with chlorine-bearing compounds. Chlorinated aromatics show strong reactivity. I’ve handled cases in labs where proper labeling and understanding spelled the difference between a smooth reaction and a safety scare. Safety sheets, waste protocols, and storage rules change based on these chemical identities.

Mistakes do happen. Tracking the carbon count or missing the chlorine creates headaches. Sometimes it’s human error, sometimes a broken workflow. In big manufacturing, quality control steps in—not just scanning formulas, but relying on automated systems that match barcodes, scan ingredient lists, and spot mislabeling before major batches head to market. These steps keep risks low and products out of recall territory.

Seeking Solutions in Chemistry Education and Practice

I’ve watched new chemistry students glaze over at “meta” and “para” naming, but once they handle the chemical, the lesson hits home. Interactive 3D models and hands-on lab time go far beyond memorizing names. Industry also leans on continuing education, pushing technicians to stay sharp. One good push is pairing theory with real-world examples: show how a pharma process can shift from blockbuster success to failed batch with a tiny structural swap.

Digital databases also help. More labs move to connected recordkeeping, linking stock bottles to digital profiles with hazard alerts and detailed formulas. This bridges gaps between classroom descriptions and factory floors. The move toward safer solvents and greener chemistry designs builds another layer. Those steps won’t make the textbook details fade—they just put stronger guardrails around the heart of chemical use: knowing exactly what you’ve got, right down to every atom in C7H7Cl.

Toxicity in the Real World

4-Chlorotoluene floats under the radar for most people outside chemical plants or labs. This colorless liquid features in the production of dyes, pesticides, and pharmaceuticals. Its sweet smell masks a sharper reality: 4-Chlorotoluene carries health risks that deserve attention both inside workplaces and in surrounding communities. I spent years in environmental safety, reviewing MSDS sheets, and I learned how easy it is for the risks of chemicals to end up minimized or ignored altogether.

What Actually Happens After Exposure?

Breathe in the fumes of 4-Chlorotoluene at a work site, and the body reacts quickly. The compound irritates mucous membranes in the nose, mouth, and throat. Coughing and headaches can start within minutes in a badly ventilated room. Splashes or vapors hitting the eyes trigger burning and redness. Skin exposure can cause dryness, dermatitis, or even blistering. These effects might sound familiar to anyone who works around solvents. Long-term studies indicate 4-Chlorotoluene acts as a depressant to the central nervous system. Dizziness, fatigue, and slowed reaction time can creep in with repeated exposure — a risk factor for on-the-job mistakes that put everyone nearby at risk.

Digging Into Chronic Exposure

OSHA and similar agencies track chemical exposure limits for a reason. Prolonged contact with 4-Chlorotoluene can stress major organs. Animal research shows liver and kidney damage after ongoing exposure to high levels. Some studies point to possible effects on blood chemistry. Long ago, I saw the toll that lax chemical handling rules took on maintenance workers: skin problems, breathing issues, tough choices between earnings and health. No one should have to face that dilemma, and with the right safeguards, those patterns stop repeating.

Environmental Spread and Community Health

4-Chlorotoluene leaks into soil or water last far beyond the workday. Once released, it spreads quickly through groundwater, sometimes affecting local wells. I’ve seen neighbors of chemical facilities worry about strange tastes in their tap water, dead spots in the garden, unexplained headaches. EPA groundwater monitoring backs up those fears—chlorinated toluenes don’t break down easily. They build up in living things, posing an ongoing hazard to pets, wildlife, and anyone growing food nearby.

Facing the Risks Head-On

Personal protective equipment helps to shield workers. Gloves, respirators, and eye protection block the most direct harm. But gear alone doesn’t solve the root problem. Modern facilities rely on strict ventilation protocols and real-time air monitors. Chemical storage areas need leak-proof containment. Spill kits stand ready near drum storage. In my time consulting on industrial safety, I urged employers to run regular hazard drills. Response training turns worst-case scenarios into manageable situations. Seldom does any single rule guarantee safety—the bigger picture always matters. Regular health screenings catch brewing problems before they reach crisis point.

Building a Healthier Future

Innovation points toward alternatives with less impact. Where possible, manufacturers have started swapping out aromatic solvents for those with shorter half-lives in the environment. Green chemistry principles urge industry to rethink old formulas. Communities get involved through citizen science and water monitoring, holding polluters accountable through data. Transparency in reporting and accessible safety training support informed choices for workers and neighbors alike. Everyone benefits from clear, honest information about what lies in the air and water, free from jargon or technical spin. Only by facing the risks can people enjoy the progress chemical science brings without sacrificing well-being along the way.

Straight Facts on 4-Chlorotoluene

4-Chlorotoluene stands out as a chemical often found in labs and factories working with dyes, agrochemicals, or fragrance ingredients. Looking at reference materials and trusted chemical databases, the boiling point lands around 162 to 163 degrees Celsius. That number is not a piece of trivia; it’s a crucial benchmark for chemists and engineers handling this substance every day. Boiling points help set the rules for storage, distillation, safety protocols, and environmental controls.

The Everyday Impact of Boiling Point Data

I recall my early experiences in chemistry labs, trying to distill compounds with as few surprises as possible. Knowing 4-Chlorotoluene’s boiling point helps set up safer processing conditions. For example, if the ventilation system isn't tuned for substances that boil in the low-160s Celsius, the risk of inhalation goes up fast. Hot aromatic vapors are no joke for respiratory health, especially in closed or poorly ventilated rooms.

Process engineers often plan distillation runs based on boiling points. Getting that number wrong spells disaster: ruined product, contaminated batches, or even runaway reactions. A clear, accurate boiling point keeps workers away from preventable accidents and helps chemists produce clean, pure products with less waste.

Risks Tied to Mishandling

In industrial settings, missing the right boiling point creates more than just paperwork headaches. I’ve seen what happens when 4-Chlorotoluene is heated too aggressively. Vapors build up, pressure mounts, and you get unpredictable leaks or even explosions. Just a few degrees above the correct range mean safety valves or containment systems get overwhelmed quickly. That’s how accidents make the news and draw regulatory fines.

Fire risk climbs with aromatic chemicals like 4-Chlorotoluene. Its relatively high boiling point doesn’t mean it can’t form flammable clouds under certain conditions. It boils at 162°C, but those vapors catch fire if they meet a spark. Labs without enforced boiling point reference checks might end up with hazardous air concentrations—inhaling chlorinated aromatics poses serious health concerns. Chronic exposure risks extend to organs like the liver, with acute cases causing headaches or worse.

Getting the Details Right

No lab or plant runs smoothly without full trust in its data. I’ve always checked multiple sources for properties like melting and boiling points. For 4-Chlorotoluene, the CRC Handbook, Merck Index, and Sigma-Aldrich’s chemical listings each confirm that 162–163°C range. Consistency brings confidence, and downstream decisions get better with each validated fact. This approach isn’t just about covering yourself. It protects workers, the public, and the environment.

Some facilities skimp on up-to-date reference libraries. There’s a strong argument for digitalizing chemical safety sheets and boiling point databases, making sure that anyone working with 4-Chlorotoluene can double-check its properties fast. Training sessions I’ve attended emphasize these details over and over—reinforcing how a single overlooked data point upends schedules and safety plans. Strong record-keeping and routine education on basic properties like boiling point keep risk low and output high.

Smart Practices to Move Forward

Having been in environments where mistakes around boiling points led to nearly fatal close calls, the value of ongoing training hits home. Teams should keep physical and digital references handy, vet newer sources, and challenge any number that looks even a little off. Awareness campaigns and simple, visible labels in storage and mixing areas make a difference. Back in the day, laminated cards with the boiling points of common solvents hung over every station. Modern equivalents like QR-scannable material safety data sheets can serve today’s busy operations just as well.

Reliable, up-to-date boiling point information—such as 162–163°C for 4-Chlorotoluene—remains one of the unsung heroes of chemical safety and productivity. People on the ground deserve tools and training that keep this fact front and center every day.

Understanding 4-Chlorotoluene Storage Risks

4-Chlorotoluene sits on the checklist of chemicals that call for extra respect in any workplace. It can spark fires and harm health, both in obvious and invisible ways. The science isn’t news: this compound can irritate skin, eyes, and airways, and its vapors can catch flame faster than many folks expect in a rushed or distracted moment. That mix of flammability and toxicity means the storage method always matters, no matter how short-term the need seems.

Maintaining Safe Conditions

The most basic wisdom still stands tall here: keep 4-Chlorotoluene sealed tight and store it in a place that won’t get hot. Manufacturers list flash points for a reason. In real-life settings, stray sparks from tools, bulbs, or static charge can light up atmospheres loaded with vapor. Keeping this chemical far from heaters, ovens, and direct sun slams the door on most avoidable mishaps. Store containers in a spot kept at room temperature or slightly cooler.

Ventilation matters everywhere flammable liquids live. Open windows alone won’t cut it—instead, choose a space with a real exhaust system designed for chemical work. Plenty of people have overlooked this, thinking a garage or backroom was “good enough.” Over time, vapor builds up without folks even noticing, turning a minor leak into a much bigger danger.

Labeling and Isolation Prevent Mistakes

Clear labeling stops minor errors from becoming major incidents. Never rely on memory or mystery bottles. Print chemical names and hazard warnings in bold, legible print. Store non-compatible substances apart—don’t stash acids, oxidizers, or food in the same cabinet or even the same part of the building. Chemical interaction isn’t selective; it’s instant and severe if the wrong lid opens next door.

Personal experience has shown some lessons the hard way: a short-lived shortcut almost always turns into a learning moment you wouldn’t wish on anyone else. Once, a drifting odor led to an emergency evacuation and a costly clean-up. No label, a cracked seal, and too many containers stacked in one spot kept everyone on edge for weeks after.

Choosing the Right Containers

Forget makeshift solutions. 4-Chlorotoluene works best in glass bottles with chemical-proof seals or official metal safety cans. Weak lids leak, corrode, or even fail—there’s no point investing in strong policy but cheap containment. Check for corrosion or bulging—these signals spell trouble early enough to fix things without drama.

Never use plastic unless it’s rated for this exact chemical. Some plastics soften, dissolve, or let tiny amounts of vapor drift through, raising indoor levels well above safety guidelines.

Respecting Human Health

Training ties all this together. Everyone who might handle, move, or clean around these containers should know the risk, the smell, and the response plan. Gloves, goggles, and aprons are not extras. If a spill happens, clean-up kits and respirators save more than money—they shield lungs and skin from exposures that add up over time. Don’t wait for rules to enforce PPE; experience teaches faster than any memo.

Local fire codes and workplace chemical safety rules don’t just protect insurance claims—they protect lives. Stay familiar with chemical safety data sheets, keep fire extinguishers on hand, and inspect everything on a regular schedule. Most chemical accidents trace back to complacency, not malice or inexperience.

Working for Long-Term Security

Constant vigilance, honest assessment, and thoughtful upgrades build the safest workplaces. Don’t cut corners; treat every drum or bottle of 4-Chlorotoluene like the first one ever handled. Invest in safe storage, strong communication, and real preparedness. The money, time, and hassle to do things right rarely compare to the costs of a single forgotten mistake.