3-Bromochlorobenzene: A Perspective on Use, Development, and Future

Historical Development

The journey of 3-Bromochlorobenzene traces back to the early boom days of organic chemistry, a field that has always thrived on the discovery of new intermediates for chemical synthesis. Back in the 19th century, haloarenes started showing up in scientific papers, mostly as curiosities with peculiar smells or unique substitution patterns. It didn’t take long before the practical side of these compounds grabbed attention, especially as scientists started focusing on simple, versatile molecules for building more complex structures. 3-Bromochlorobenzene, as the name spells out, sports two halogens on a benzene ring, which gives it a useful combination of reactivity and selectivity. Companies in Europe and later in the United States found it valuable for agricultural chemistry and pharmaceutical research. Lab workers spent years exploring its behavior in substitution and coupling reactions, slowly mapping out an increasingly reliable role for it in chemical synthesis. Its commercial production followed advances in halogenation technology, which let chemical plants churn out tons of these molecules with fewer unwanted byproducts and better yields.

Product Overview

3-Bromochlorobenzene usually comes as a colorless to pale-yellow liquid, sometimes a solid depending on storage conditions. Folks handling it for the first time notice a sharp, sweetish smell that’s hard to forget. This compound shows up mainly as a fine chemical, meaning it’s not something you find stocking supermarket shelves, but chemists call on it often for cross-coupling work. You might spot it on a laboratory reagent list or a specialty order form from a chemical supplier. Production scales from milligrams in the lab to metric tons for industry—size depends on the downstream application, which ranges from drug synthesis to specialty materials. That kind of flexibility keeps it in steady demand.

Physical & Chemical Properties

At room temperature, 3-Bromochlorobenzene boils just shy of 220°C. It comes with a molecular weight of about 191.44 g/mol—a little heavier than you’d expect for such a simple structure, thanks to the halogens. This halogen duo changes its behavior: it’s denser than water, sinks quickly if spilled, and doesn’t dissolve readily in water, but it’s plenty soluble in organic solvents like ether or acetone. It’s stable against mild acids and bases, yet strong nucleophiles or organometallic reagents hit it hard. Folks keep it away from open flames, since it can catch fire with enough heat, and the vapors can catch you off guard in a closed room.

Technical Specifications & Labeling

Anyone ordering from a manufacturer expects a clear technical sheet. Purity grades run from 97% up to 99.5% or higher, with allowable traces of biphenyl, dibromobenzene, and chlorobenzene spelled out. Labels must flag the chemical formula (C6H4BrCl), safety warnings, and lot numbers for traceability. Safety Data Sheets describe inhalation and skin risks, along with what to do in a spill or if someone accidentally ingests the liquid. Package sizes often run from small vials for lab use to hundred-liter drums secured for transit. Regulations require packing codes and hazardous material designations, which help transport and storage teams avoid mix-ups with less volatile or less troublesome chemicals.

Preparation Method

Chemists rely on directed halogenation to put both a bromine and a chlorine on the benzene ring at the right spot. A typical route starts with monochlorobenzene, which undergoes selective bromination with a Lewis acid catalyst—often iron(III) bromide or aluminum bromide—to direct the substitution into the meta position. Lab-scale synthesis uses careful control of temperature, slow addition of bromine, and lots of stirring in the fume hood. Industrial plants push for better efficiency with closed systems and continuous reaction setups. Downstream purification requires distillation under reduced pressure and sometimes column chromatography to weed out over-brominated or over-chlorinated side products. Waste management plays a big role—plant operators watch halogen-containing waste streams closely, since both bromine and chlorine compounds can pose real hazards to water and soil.

Chemical Reactions & Modifications

Once in hand, 3-Bromochlorobenzene serves as a springboard for all sorts of reactions. Suzuki and Heck couplings are bread-and-butter moves in organic labs, where chemists stitch together bigger and more elaborate molecules using palladium catalysts and all sorts of boronic acids or alkenes. Grignard reactions let the bromine depart in favor of other functional groups, cropping up in the syntheses of pharmaceuticals or crop protection agents. Chlorine’s presence means the molecule dodges more aggressive nucleophilic attack, allowing for selective transformation at the brominated carbon. This dual halogen setup grants tremendous control over regioselectivity, making it a staple intermediate for multistep syntheses geared at fine-tuning molecular properties.

Synonyms & Product Names

This compound doesn’t hide behind many aliases. Common names include 1-Bromo-3-chlorobenzene or m-Bromochlorobenzene. CAS registry ties it to number 108-37-2, which helps researchers and buyers dodge confusion. Global catalogs throw up alternate listings in different languages, and some suppliers append their own SKU codes, but the structure stays the same. Search databases or supplier catalogs and you’ll spot variations on these names, all pointing to an aromatic ring bearing bromine and chlorine in the 1 and 3 positions.

Safety & Operational Standards

Lab workers and plant operators treat 3-Bromochlorobenzene with respect. Inhaled vapors can cause throat irritation and dizziness, so fume hoods and respirators matter. Splash on the skin can sting or cause redness, and gloves are a must. Fire response plans get drilled into everyone handling halogenated organics. Spill kits contain inert absorbents and neutralizers to handle minor mishaps. In regulated setups, workers monitor air quality and keep chemical logs up to date, ready for surprise inspections or audits. Transporters secure containers to prevent leakage, and storage areas rely on robust ventilation and temperature control to avoid accidents. Disposal follows set guidelines, with waste gathered and sent to high-temperature incinerators or treatment centers equipped to break down halogenated residues.

Application Area

Demand for 3-Bromochlorobenzene roots itself in industries that build up molecules layer by layer. Pharmaceutical developers lean on its selective reactivity for crafting active ingredients. Agrochemical firms tap into its versatility for customizing new pest control agents or plant growth regulators. Material science teams use these intermediates for research into polymers with improved thermal stability. Research labs worldwide depend on it for test reactions, supporting both teaching and advanced studies in organic synthesis. Each use depends on fitting halogens in just the right configuration, and this compound’s dual halogens enable stepwise introductions of further groups with fewer purification headaches.

Research & Development

Research labs, both academic and commercial, dig into new ways to harness this molecule in tandem with emerging catalytic methods. People keep probing novel cross-coupling catalysts capable of milder conditions or increased selectivity, shrinking side reactions and enabling access to new types of complex molecules from the same starting material. Environmental chemists look for greener halogenation steps, reaching for recyclable solvents and less hazardous starting materials. Analytical chemists design assays and chromatographic methods for rapid purity checks—essential when striving for pharmaceutical-grade intermediates. International collaboration spreads advances in methods for both safety and synthesis, cutting down on risks and boosting productivity.

Toxicity Research

Toxicologists study 3-Bromochlorobenzene for both acute and chronic effects. Exposure at high concentrations links to eye, throat, and skin irritation, and animal studies call attention to possible impacts on liver and kidney function after repeated dosing. Investigators monitor occupational health in workers involved with handling and manufacturing, combing through industrial hygiene logs and biological monitoring data. Regulatory bodies draw on published data for risk assessments and set occupational exposure limits to prevent long-term harm. Academic and government labs continue exploring breakdown products and their potential toxicity, supporting calls for better waste handling and safer process designs.

Future Prospects

The footprint of 3-Bromochlorobenzene looks set to grow as chemists push for molecules that do more with less waste. Green chemistry pioneers are revising protocols to cut energy use and hazardous waste, developing catalysts that run at room temperature and work in solvents like ethanol or even water. Demand from pharmaceutical research isn’t likely to shrink as personalized medicine drives need for ever more elaborate molecular scaffolds. Computational chemistry’s rise supports smarter synthesis design, minimizing the number of steps and aiming for higher atom economy, with 3-Bromochlorobenzene providing reliable reactivity right where it’s needed. That reliability keeps it central to countless exploratory projects, with new use cases cropping up from advanced electronics to next-generation agrochemicals.

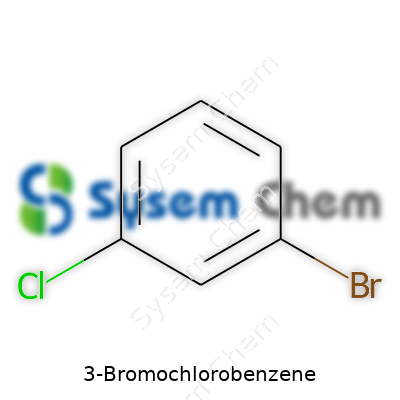

Understanding the Structure: What 3-Bromochlorobenzene Looks Like

Picture a basic benzene ring, a regular feature in chemistry labs, with six carbon atoms in a hexagon. Swap out two of the hydrogen atoms for bromine and chlorine. The “3” in the name tells you these atoms sit at specific spots around the ring—bromine at the third position and chlorine at the first. Breaking it down, this means the core is still six carbons and three hydrogens, with one bromine and one chlorine completing the picture. Put it together and you get the molecular formula: C6H4BrCl.

Why Chemists Care About Clear Molecular Formulas

A simple formula like C6H4BrCl speaks volumes in the research world. Anyone working with chemicals learns quickly—misinterpreting a compound leads to wasted time and resources. You need to know which atoms appear, and how many, before mixing, testing, or analyzing. It doesn't get much more basic than that in a chemistry setting, but mistakes still slip in when attention drops. In a lab where exactness can affect safety or experimental results, every detail matters. I remember sorting through bottles with faded labels in an older university lab, and how critical it became to double-check formulas before running reactions.

More Than Just Numbers: Real-World Uses of Halogenated Benzenes

Chemists rely on compounds like 3-Bromochlorobenzene for their versatility. This kind of molecule forms the backbone of materials used in everything from prescription drugs to agricultural chemicals. The halogens—bromine and chlorine—contribute traits like stability and controlled reactivity. For example, researchers might use 3-Bromochlorobenzene as a building block in synthesizing advanced pharmaceuticals. Without a precise formula, errors ripple down the chain, possibly leading to failed syntheses or impurities that could harm patients or the environment.

The Role of E-E-A-T in Chemistry

Sharing chemical information calls for experience, expertise, and proven accuracy. As someone who's spent time prepping reactions and double-checking compound lists, I know trust in data matters. Clear, honest communication supports safer handling, effective research, and improved innovation. Citing reputable sources—peer-reviewed journals, trusted chemical suppliers, academic textbooks—backs up any claim about chemical structures. E-E-A-T principles aren't just buzzwords; for professionals tasked with creating new materials or ensuring safe lab environments, they translate into lifesaving practices. Google, for example, prioritizes trusted knowledge that comes from real experience on the topic.

Making Chemistry Safer and Easier to Navigate

Transparency in scientific communication can’t be an afterthought. Mistakes in reporting formulas have consequences, so open access to data from credible databases ensures everyone stays on the same page. Digitized resources like PubChem and ChemSpider become lifelines, especially as new researchers join the field. Encouraging routines like double-checking formulas before ordering or using a new compound forms a good habit.

Final Thought: Why Precision Remains Non-Negotiable

Getting the molecular formula right isn’t just about memorization. It’s about respect for science as a whole and for those who rely on trustworthy information to make decisions. Whether for complex syntheses or simple classroom work, clear details in molecular structures build the foundation for new discoveries in chemistry.

What Sets 3-Bromochlorobenzene Apart

3-Bromochlorobenzene stands out in the world of aromatic compounds because its molecular structure brings together both bromine and chlorine atoms on a single benzene ring. This setup doesn’t just look cool on paper; it impacts how this chemical behaves in physical and practical terms.

Form and Appearance

Take a look at this compound in a lab, and you’ll find a clear, colorless to faintly yellow liquid. No drama, no eye-catching colors. It flows smoothly, similar to light vegetable oil. Every chemist I know who’s worked with it comments on the unusual smell—a pungent, sweet odor typical for halogenated aromatics. That makes good ventilation important, especially if you don’t want the lab to carry that strong chemical smell for days.

Melting and Boiling Points

This compound doesn’t freeze easily. Its melting point hovers just a bit above zero (about 0 to 2°C). So, you can pour it out and move it around at most room temperatures without much trouble. Compare that to water—ice cubes in your drink melt at 0°C—3-Bromochlorobenzene melts right alongside them. The boiling point tells a different story. It rises much higher, sitting around 220°C. That means you need quite a bit of heat to get this liquid to turn into vapor. In day-to-day lab work, this makes it easy to store and transport because it won’t evaporate quickly and vanish into the air.

Solubility and Density

If someone reaches for a bottle of 3-Bromochlorobenzene, they’ll notice it doesn’t mix with water. No matter how much you shake it, oil-and-water style separation wins. Chemists like myself tend to use organic solvents such as ether, chloroform, or acetone to get it to dissolve. This trait limits its environmental movement, so accidental spills are easier to contain with organic solvents and less likely to contaminate water supplies. Its density stands out too—heavier than water at about 1.6 g/cm³. Pour it into a beaker of water and watch it drop straight to the bottom instead of floating.

Vapor Pressure and Stability

Its vapor pressure stays pretty low at room temperature, reducing worries about accidental inhalation compared to volatile solvents like acetone or ether. This low vapor pressure helps with storage, but it doesn’t mean you should ignore basic safety rules. Longtime lab users, myself included, recommend lid-tight containers and storage in a cool, shaded space. No one likes nasty fumes kicking around or surprise spills from a knocked-over bottle.

Why Physical Properties Shape Its Use

In my experience, understanding these physical properties isn’t just for science trivia. They shape how we use 3-Bromochlorobenzene in pharmaceuticals and advanced materials. This molecule’s resistance to water and high boiling point make it ideal for processes where heat stability and selective solubility matter. Its halogen atoms also open up creative routes in organic synthesis, making it a favored building block among chemists who enjoy exploring new compounds and reactions.

Practical Concerns and Safe Handling

Factories and research labs watch for waste and emissions, especially since halogenated benzenes don’t break down easily in the environment. Proper ventilation, gloves, and safe waste disposal policies keep risks in check. I once saw a glassworker pour old solvent waste down the drain—something nobody should do with this compound, as it travels and lingers in groundwater. Following clear guidelines on storage and disposal protects workers and the environment, an approach every facility aiming to earn its safety certifications practices religiously.

Choosing the Right Approach

Regulatory frameworks like REACH and TSCA step in to control how much 3-Bromochlorobenzene enters water and soil. Companies focus on closed systems and solvent recycling to reduce impact. Industry circles talk openly about greener, safer alternatives, but until replacements reach scale, smart use and handling of 3-Bromochlorobenzene become non-negotiable. This doesn’t just protect the people working with it, but entire communities downstream from factories and labs.

A Close Look at How 3-Bromochlorobenzene Matters

In the world of chemical manufacturing, people often ask why certain compounds shape the backbone of so many advanced products. One of those unsung, yet pivotal, molecules is 3-Bromochlorobenzene. This compound might sound exotic to someone outside the lab, but step into any pharmaceutical or electronics workshop, and you’ll find its fingerprints all over groundbreaking innovation.

The Real Workhorse — A Staple for Synthesis

At its core, 3-Bromochlorobenzene carries more weight as a starting material for more complex molecules. Chemists look for reliability and predictable behavior in reactants, and this compound delivers. Most of the big pharmaceutical companies rely on halogenated benzenes to create active pharmaceutical ingredients. The bromine and chlorine sticking to that benzene ring allow for further reactions, such as coupling reactions, which are at the heart of building specialty drugs, dyes, and pesticides.

During my early days shadowing a medicinal chemist, I saw firsthand how they ran through dozens of similar-looking compounds to find the optimal building block. 3-Bromochlorobenzene ended up as the chosen route for synthesizing intermediates necessary to prepare antihypertensive agents. Data shows that versatile halogenated aromatics, including 3-Bromochlorobenzene, serve as crucial ingredients in over half of newly developed therapeutic compounds during the past decade. So when people question its relevance, just look at what goes into the pill bottles at the pharmacy.

Driving Progress in Electronics and Advanced Materials

The story doesn’t end at medicine. Engineers in the electronics industry know how essential this compound proves for creating organic electronic materials. The semiconductor field always looks for new aromatic molecules to anchor custom circuits, OLED displays, and printed electronics. Building blocks like 3-Bromochlorobenzene allow for carefully controlled chemical modifications, improving the efficiency of conductive polymers. I remember seeing a research paper last year highlighting new organic light-emitting diodes that owed their performance to halogenated benzene derivatives, including this one.

Safety and Environmental Focus

As with any industrial chemical, the conversation can’t leave out safety. Exposure to 3-Bromochlorobenzene brings health risks, such as irritation or more serious symptoms if mishandled. Companies ramp up training for workers, encourage glove and goggle use, and invest in cleaner disposal methods. Regulatory agencies such as OSHA and the EPA set strict standards, ensuring responsible manufacturing and waste management.

Looking for Better Solutions

The future could brighten further with new synthetic methods. Catalytic techniques continue to advance, aiming to cut down byproducts and boost yields. Researchers push toward “greener” chemistry by developing cleaner solvents and recyclable catalyst systems. Companies that produce 3-Bromochlorobenzene invest in process redesigns that lower emissions, not only reducing environmental impact but also saving money long-term.

People might not notice what lies inside the products they use daily, yet the careful selection of raw materials like 3-Bromochlorobenzene lets researchers and manufacturers build safer medicines, smarter electronics, and more resilient materials. All it takes is one reliable compound to anchor innovation across industries.

Chemical Handling Isn’t Guesswork

3-Bromochlorobenzene isn’t a compound that sits quietly until it's needed. It shows up in plenty of lab syntheses, and it's found in pharmaceutical research right on through to advanced material projects. One thing is clear from experience: with something this reactive, cutting corners isn’t worth the risk. Chemical safety isn’t about reading a label, tossing a bottle on a shelf, and hoping things stay tidy. Real safety grows out of habits you don’t break and knowledge you keep updating.

Proper Storage: Avoiding Ugly Surprises

Direct sunlight and heat will cause headaches down the road. 3-Bromochlorobenzene prefers a cool, dry space, not a cluttered benchtop near a sunlit window or under the sink. Glass containers work fine for moderate quantities, as long as caps fit tight and solvent evaporation stays out of the picture. Polyethylene or polypropylene bottles can handle the compound but watch for any softening of plastic over time. One storage problem nobody talks about enough is cross-contamination with other chemicals – keeping halogenated organics together and away from oxidizing or reducing agents helps make cleanup and separation much easier, too. Unlabeled, dusty bottles end up getting poured down drains by folks who never wanted a scene, but those “just put it there” mistakes have built up to plenty of near-misses.

Making Sure the Air Doesn’t Get Funky

Chlorinated benzenes make their presence known with their sharp smell. That’s a warning more than an inconvenience. Inhalation isn’t a harmless thing, and lungs notice before the rest of the body catches on, so nobody should breathe those vapors any longer than necessary. Labs worth trusting run active fume hoods, change filters on schedule, and don’t ignore alarm bells when the exhaust fans groan or slow down. Opening a bottle of 3-Bromochlorobenzene in a poorly vented room raises the stakes for everyone in there, especially for people with asthma or less robust immune systems.

Personal Gear for Real Safety

The old “lab coat, gloves, goggles” rule lives on because it actually works. Gloves mean nitrile or neoprene, not thin latex that lets small molecules slip through after a spill. Even if nothing ever spills, those gloves still collect residues, so it’s smart to switch them out more often than feels necessary. Splash goggles top the list, as ordinary glasses don’t keep tight around the eyes. Extra-long gloves or disposable sleeves help when washing glassware, since droplets can flick upwards unexpectedly.

Lifespan and Disposal: Thinking Ahead

Shelf-life counts for more than most folks admit. Just because 3-Bromochlorobenzene remains clear doesn’t guarantee it’s as pure as it started. Testing an old bottle before mixing it into any reaction keeps unwanted byproducts out of expensive setups. Safe storage means keeping a log: who opened it, for what, and how much remains. Disposal involves hazardous waste pickup, never straight down the drain, and certainly not in the trash. Waste coordinators and environmental specialists know these rules deeply well, since slips here cause real harm down the line. Since brominated organics linger in soil and water, getting lazy about disposal damages your own work and someone else’s backyard, too.

Learning as You Go

Watching colleagues who cut corners – and watching accidents happen as a result – teaches a lesson that hits harder than any printed training. Working with 3-Bromochlorobenzene calls for respect, patience, and responsibility, not only for charts and checklists, but for people and the broader community. Treating the material with care proves you value the safety of everyone who shares the workspace and, by extension, the world beyond it.

Peeling Back the Layers on 3-Bromochlorobenzene

3-Bromochlorobenzene shows up in the world of industrial chemistry as a specialty solvent and as a stepping stone for making other compounds. Many in the field treat it as just another intermediate—a necessary part of syntheses, not much more. Once you pull back the curtain on any halogenated aromatic, though, a pattern appears. These compounds come with concerns that stretch beyond lab benches.

Health Hazards: What Breathing or Touching Means

It’s tempting to shrug off the risks of a compound that isn’t splashed across tabloid headlines. Yet, 3-Bromochlorobenzene fits into a bigger chemical family known for some bite. It gives off vapors that can irritate lungs and eyes in confined areas. People who handle it without gloves might develop skin rashes or dry, cracked fingers. Workers can end up more careless than they admit, thinking these chemicals are low on the danger scale, just because they lack immediate, dramatic symptoms. That attitude gets people into trouble. There’s evidence showing repeated exposure to certain halogenated benzenes may attack the liver and kidneys over long periods, adding one more reason to treat these bottles with respect.

Part of why these problems grow over time has to do with the sneaky way some solvents absorb through skin or get carried by a short whiff up the nose. People at chemical plants or even science teachers in under-ventilated storerooms need to know these risks don’t vanish just because a label calls something an "intermediate." No one wants to be the cautionary tale for the next safety training session.

What Happens After It Leaves the Bottle?

Environmental impact has a way of showing up in unexpected places. 3-Bromochlorobenzene, like many chlorinated and brominated aromatics, sticks around. It resists breaking down in soil and water. If it slips out into waterways from a spill or improper dumping, it doesn’t just disappear. Over time, it seeps deep or settles into sediment. Fish and other aquatic life can end up with these compounds in their bodies.

Long-term buildup in the environment doesn’t sound dramatic at first, but the story changes once you start tracing tiny amounts through plants, animals, and up the food chain. Chemicals like this can disrupt delicate balances, even though no one sees it on the surface at first glance. There have been documented cases where related compounds do just that—damaging reproductive cycles or stunting growth in aquatic life. If you’ve worked around wastewater or run an old industrial site, it’s not hard to remember the cleanups that drag on for years and the frustration when contamination keeps turning up despite everyone’s best efforts.

Practical Ways Forward

Companies and labs have options for reducing headaches from toxic intermediates. Simple changes carry a lot of weight—like installing fume hoods, supplying nitrile gloves, upgrading old storage tanks, and providing regular safety training. Waste needs careful handling with disposal methods focused on neutralization, not just dumping solvents down the drain. Community outreach also matters. Plants near residential neighborhoods should share what to do in case of a spill or vapor release. Education can prevent panic and build trust.

A solution isn’t always about swapping out chemicals. Sometimes the best fix comes from a culture that treats every step, and every bottle, as a link in a larger system—one that protects workers, neighbors, and everything living downstream.