1-Bromobutane: Insight into a Staple Organic Chemical

Historical Development

1-Bromobutane holds a classic spot in the family of alkyl halides. Its story winds back to the early days of functional group transformations in organic labs at the end of the nineteenth century. As students and researchers mapped the puzzle of carbon frameworks, the simple switch of hydrogen for bromine in butane revealed a reactivity that made alkyl bromides stand out in synthetic routes. Before the flood of modern petrochemical plants, small batches often came from the reaction between butanol and phosphorus tribromide. Over time, as scale and safety improved, chemical producers locked in methods that trusted the efficiency and predictability of halogenation reactions. Many old organic chemistry textbooks recount how the rise of halogenated organics like 1-bromobutane ushered new teaching standards and experimental approaches, connecting classroom learning to industrial practice.

Product Overview

In clear, colorless liquid form, 1-bromobutane doesn’t parade a smell as sharp as familiar solvents, but its faint, sweet odor reminds most chemists of lab benches layered with glassware. The compound’s straightforward structure—four carbon atoms in a straight line, capped off by a bromine atom—means it serves as a practical, predictable building block. Besides acting as an alkylating agent, it forms the backbone for turning out compounds in pharmaceuticals, fragrances, and specialty polymers. In my years of working with organic intermediates, 1-bromobutane always stands out for its reliability in reactions and its versatility in schemes where replacing or extending carbon chains matters.

Physical & Chemical Properties

With a boiling point hovering around 101°C and a melting point near -112°C, 1-bromobutane keeps its liquid state under normal storage. Its density of roughly 1.27 g/cm³ makes it denser than water, so it settles in the bottom layer if spilled in an aqueous solution. Solubility tells a story: barely dissolving in water but freely mixing with most organic solvents such as ethanol, diethyl ether, and chloroform. Its relatively low polarity compared with other brominated compounds means it slips easily into nonpolar reaction mixtures and resists mixing with water. Chemists appreciate its moderate reactivity; the bromine atom invites nucleophilic substitution and elimination, underscoring its wide industrial and academic use.

Technical Specifications & Labeling

Typical technical grade 1-bromobutane ranks above 99% pure, flashing an assay label that assures minimal presence of isomers and residual water. Labels must list the UN number (UN 1126), hazard statements such as “harmful if inhaled” and “irritates eyes, skin, and respiratory tract,” along with pictograms for flammability and environmental hazards. In my experience, true compliance isn’t just about ticking boxes—it shows respect for safe handling and environmental care, and supports the traceability that regulators and researchers alike demand.

Preparation Method

In the bench-scale process, 1-bromobutane comes to life through a straightforward nucleophilic substitution. Mixing n-butanol with a source of bromide—hydrobromic acid works, but a dash of sulfuric acid can boost yield—kicks off the reaction. Industrial outfits often shift to phosphorus tribromide for less water, higher purity, and less byproduct. Some years back, I learned to appreciate the efficiency and sharp separation between organic and aqueous layers during the workup, which simplifies the purification step using distillation. Scale-up involves attention to stoichiometry, exothermicity, and proper ventilation, especially because hydrogen bromide gas escapes in larger reactions.

Chemical Reactions & Modifications

Bromobutane unlocks a wide set of transformations. In the SN2 pathway, the bromine leaves readily when attacked by nucleophiles like cyanide, acetate, or amines. That produces butyl derivatives of all stripes: nitriles, ethers, or amines for further transformation. Heat and a strong base tip the balance toward elimination, giving 1-butene. Working with this compound means understanding its behavior not just in a vacuum, but in a range of solvents and reaction partners—subtle choices can steer a pathway toward substitution rather than elimination. These skills reinforce the hands-on aspect of chemical synthesis, building expertise that reaches beyond theory.

Synonyms & Product Names

1-Bromobutane answers to several names in the chemical world. Some catalogs list it as n-butyl bromide or butane, 1-bromo-. The CAS number, 109-65-9, identifies it unambiguously for ordering and regulatory tracking. Everyday reference usually shortens to “n-butyl bromide” in lab slang, but clarity matters. Especially sorting stocks in shared research spaces, I’ve seen confusion melt away just by sticking to proper chemical nomenclature and cross-checking labels and safety data sheets.

Safety & Operational Standards

Safety comes into focus any time 1-bromobutane leaves the bottle. Skin contact or breathing vapors triggers irritation, so gloves, goggles, and fume hoods form the baseline protective gear. Laboratories with solid training programs highlight the compound’s flammability and toxic decomposition products—including bromine gas and carbon monoxide—especially during fires. Storage in cool, ventilated areas with closed, labeled containers limits unnecessary exposure. In industry, spillage protocols include containment, neutralization, and proper ventilation. Regulatory bodies demand that shipments comply with international standards, including proper packaging and documentation, reducing risk both to workers and to the public.

Application Area

The bread and butter uses of 1-bromobutane fall in organic synthesis. It shows up in pharma research, where it helps turn out active intermediates and drug discovery toolkits. Fragrance and flavor makers value its role as a precursor for fruit and nut aromas. In the plastics industry, its addition to monomer blends tunes mechanical and chemical properties of specialty polymers. I’ve seen green chemistry trends spark renewed interest in butyl bromide’s reusability and low impurity load for cleaner downstream products. Its role as an initiator and crosslinker extends its impact well beyond the bottle, shaping everything from lab-scale swatches to industrial-scale production lines.

Research & Development

Active research targeting greener synthesis and better catalytic methods pushes the boundaries for making 1-bromobutane. Teams look for biomimetic approaches; new biocatalytic strategies using engineered enzymes promise selectivity and fewer waste streams. Analytical labs refine their detection, using gas chromatography and infrared spectroscopy to measure trace impurities and meet global quality standards. One angle I followed closely involved one-pot tandem reactions, shrinking the number of steps needed and improving energy efficiency. These innovations often bubble up from collaborations between academic chemists and process engineers, setting new benchmarks for sustainability and efficiency.

Toxicity Research

Toxicologists call 1-bromobutane moderately hazardous. Data points to acute impacts like headaches, dizziness, and mucous membrane irritation after accidental inhalation or skin exposure. Animal studies flag potential for liver and kidney effects with chronic exposure, though most reports show limited bioaccumulation and fairly rapid excretion in mammals. Environmental research traces some persistence and mobility, so best practices stress prompt cleanup and waste treatment. Continuous review of workplace monitoring and exposure limits flows from the findings of both regulatory agencies and occupational health studies, grounding safety measures in real-world exposures.

Future Prospects

Sustaining relevance in a shifting chemical landscape means 1-bromobutane must plug into trends tied to efficiency, low environmental impact, and regulatory compliance. Demand grows for brominated intermediates in pharmaceuticals and advanced materials. Process chemists seek catalysts that cut waste and speed up conversions. Biomedical researchers track biocompatibility and biodegradability of butyl-derived molecules, hoping to broaden product portfolios with safety and sustainability up front. Watching regulatory climates tighten, chemical suppliers invest in closed-loop systems and cleaner syntheses, seeking out new customers who value both technical standards and responsible production. As industries shift toward circularity and green sourcing, my hunch is that 1-bromobutane will find plenty of new hands to work with, far beyond its old roots in academic research.

A Chemical With a Purpose

It’s easy to walk past rows of glass bottles in a lab and feel like their labels belong in another world. 1-Bromobutane doesn’t draw a crowd, but those who work with it know it packs a practical punch in the world of organic chemistry and manufacturing. This colorless liquid, which carries a faint odor, often acts as a building block for making other, more complex compounds—kind of like flour in baking. Chemists often use 1-Bromobutane to make things happen in the lab. It’s a simple molecule, but it helps piece together a range of products used both in industry and research.

Key Ingredient for Chemical Synthesis

1-Bromobutane serves as a classic alkylating agent. That means it adds a “butyl” group to other molecules, which can change their function or behavior. Think of it like adding a new part to a car that suddenly lets it handle different roads. In the world of synthetic chemistry, 1-Bromobutane slips into reactions to help create drugs, flavoring agents, dyes, and perfumes. Students in undergraduate organic chemistry courses learn about it through tests known as nucleophilic substitution reactions, which illustrate core concepts in chemical transformation. For many chemistry majors, this is their first hands-on encounter with how small changes in molecules can lead to real products.

Making Pharmaceuticals and Everyday Products

Pharmaceutical companies often turn to 1-Bromobutane during the early stages of drug creation. Drug molecules need to be shaped just right to fit biological targets. This compound helps tweak molecular skeletons so that other useful groups can be attached where they’re needed. It doesn’t stop there. Perfume makers rely on creative chemistry to create scents that linger. Adding the right hydrocarbon chain, made possible using something like 1-Bromobutane, can hold a scent molecule together. Dyes and other specialized chemicals also sometimes come about with a hand from this compound. Most finished goods don’t contain the original 1-Bromobutane, but its presence down the manufacturing line is essential for getting certain ingredients where they need to be.

Industrial Uses and Real-World Presence

The chemical plants handling this compound keep safety protocols tight, because 1-Bromobutane can harm health through skin contact or inhalation. Its most frequent appearance outside of labs is in the making of n-butyllithium, another powerhouse chemical used in the creation of both pharmaceuticals and specialty plastics. Factories using lithium compounds for batteries or syntheses count on 1-Bromobutane to keep their processes on track. This is a behind-the-scenes ingredient, quietly supporting industries and innovations most people never see.

Importance of Care and Oversight

Accidents involving 1-Bromobutane highlight the fact that progress in chemistry always carries responsibilities. Back in my student days, our instructors never left us alone for long when handling such reagents. Exposure can lead to dizziness or worse, so gloves, goggles, and strong ventilation always played a role in the lab. Today, strict worker safety standards govern how this compound gets stored, shipped, and used. Electronic logs, air monitoring, and emergency plans are the norm, not the exception. Environmental oversight also matters, since releases of brominated compounds can cause long-term harm to ecosystems. Industries have stepped up to limit emissions and boost recovery, but accountability makes the difference between safe progress and real risk.

Smarter Chemistry, Safer Outcomes

Over the years I’ve seen research teams chase ways to cut out hazardous chemicals or handle them more safely. Some new processes use milder substitutes, but many reactions still benefit from the reliability of 1-Bromobutane. The future likely holds greener, cleaner chemical methods. In the meantime, rigorous safety training and openness about risks help keep both workers and communities protected while industry continues to lean on chemistry’s reliable building blocks.

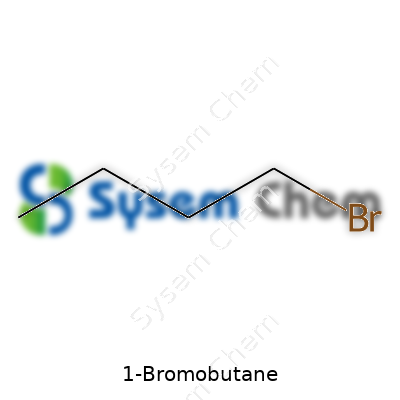

Understanding the Structure

1-Bromobutane is a simple name on paper, but behind that name sits a handful of atoms telling a bigger story. The molecular formula for 1-bromobutane is C4H9Br. It comes down to a four-carbon chain where a single bromine atom attaches to the end. One end of the chain starts with bromine, and the rest of the space fills up with hydrogen, nothing fancy, just basic organic chemistry at its best. This molecule turns up in university labs more often than people expect, reminding us how accessible real-life chemistry can be.

The Role of Carbon Chains in Real Life

Organic chemistry tends to make people think of endless diagrams, but small molecules like 1-bromobutane show up in a surprising number of experiments, especially during undergraduate years. Back in the days of one of my early lab classes, we used 1-bromobutane to learn about nucleophilic substitution. Students would study the reaction as bromobutane swapped out the bromine for another group. The reaction set the stage for so many practical skills—handling glassware, calculating yields, and understanding the details of organic processes.

Why C4H9Br Matters

With 1-bromobutane, having just four carbons in a straight line means its reactivity is predictable. In everyday teaching labs, this predictability has value. The molecule provides clues about how carbon chains interact with other reagents, and the presence of bromine adds just enough complexity to keep concepts interesting without overwhelming a beginner. Industry puts 1-bromobutane to use as a starting material for more complex compounds and pharmaceuticals. Simplicity doesn’t mean lack of utility—being able to trace changes at a molecular level trains future chemists to solve much bigger problems.

Safety and Environmental Perspectives

Safety has to come up, especially with halogenated compounds. My chemistry professors drilled it in: gloves, goggles, and fume hoods. 1-Bromobutane has a strong smell, almost impossible to forget, and it can cause headaches if the lab isn’t ventilated. Beyond personal safety, today’s labs have to pay close attention to waste disposal. Even though this molecule is small, halogenated waste requires separate handling. Proper disposal protects groundwater and supports sustainable labs. Thinking back, anyone who’s taken out chemical waste from a student lab knows the routine, and those early lessons stick with you when setting up future experiments or working in bigger facilities.

Solutions and Better Practices

Schools and companies might rely on 1-bromobutane, but they also have growing responsibility to reduce waste and exposure. Some labs explore using greener alternatives or closed systems to limit evaporation. Others invest in better ventilation or automated handling to reduce student mistakes. On the chemical side, researchers keep looking for reactions that don’t require halogenated solvents or develop strategies to reclaim and reuse them. Building safer workspaces rests on habits and small investments: regular equipment checks, clear labeling, and accessible safety training. Over years of lab work, these steady routines prevent the small mistakes that could snowball into bigger problems.

Future Directions

Staying informed helps. Students and young chemists should know the name C4H9Br, but learning doesn’t stop with the formula. Each time you see or use a molecule like this, you’re joining a thread that runs through real-world problem solving, careful safety practices, and ongoing efforts to make science as responsible as it is effective.

An Honest Look at 1-Bromobutane’s Risks

1-Bromobutane isn’t talked about much outside chemist circles, but plenty of students, lab pros, and factory workers cross its path. If you ever had to perform organic syntheses, you may have worked with this clear, colorless liquid. When I stepped into academic labs years ago, that particular bottle with the faintly sharp odor made me pay close attention to my gloves and ventilation.

People ask if 1-bromobutane is dangerous. According to the U.S. National Library of Medicine’s Haz-Map database, exposure can irritate eyes and skin, mess with your lungs, and if you breathe in a lot, drowsiness and headaches may follow. Students and techs handling it sometimes slip up, and those little exposures can add up. I’ve seen enough minor chemical burns and felt enough coughs to take the label warnings seriously.

Human Health Effects

The most immediate problems come from direct contact or inhaling vapors. Forgetting goggles or gloves can mean stinging eyes or redness on your skin within minutes. NIOSH recommends protective gear any time you uncork this stuff. The chemical even sneaks through some basic gloves, making nitrile or neoprene a better choice. Many researchers develop habits of double-gloving and changing gear as soon as they sense a spill.

A poorly ventilated lab can trap vapors, making someone woozy halfway through an experiment. Breathing these vapors over months, even at low amounts, sometimes results in problems you notice only later. Chronic exposure shows up as issues with the nervous system or even kidney function. Scientists still debate the magnitude of long-term risks, but most agree that erring on the side of caution beats regret.

Environmental Impact

Spilling 1-bromobutane on surfaces or drains is bad news. The chemical doesn’t break down easily in nature, and brominated organics often linger in water and soil. I remember one university scrambling to clean up a spill next to a storm drain after a careless mistake; the decontamination ran up real costs, and nearby plants wilted for weeks. Environmental agencies demand responsible storage and waste handling because of those risks.

Better Practices and Reducing Hazards

Labs that stay vigilant keep 1-bromobutane locked up, away from sunlight and open flames, never putting more than a small bottle on the bench. Clear labels, proper fume hoods, and training on what to do in a spill make the difference between a regular workday and an emergency. The ACS Chemical Health and Safety journal documents plenty of accidents traced directly to skipped safety checks or rushing through prep.

Some workplaces try to swap in less toxic alternatives or even redesign syntheses so 1-bromobutane isn’t needed. These changes take planning and money. Not every college or manufacturer can afford safer substitutes for classroom demonstrations, for example. But the push continues, especially as more people realize the value in prevention, not just remediation.

Paying Attention Is the First Step

Respecting chemicals like 1-bromobutane boils down to habits learned in the trenches. Using the right glove, checking the fume hood fan, and never dumping extra down the drain may seem like small steps, but over time they keep people and nature safer. Reading safety data sheets and sharing stories of close calls helps, too. Watching out for yourself and your coworkers matters far more than bravado in the lab.

Storing Chemicals: Lessons I’ve Learned

Every chemical shelf in the lab tells a story. The times I spent in a college organic lab, talking over procedures with professors, left a deep respect for how important storage really is. That smell when someone leaves a solvent bottle open says a lot: chemicals, even ones that look harmless, can turn risky fast. 1-Bromobutane counts among these. Colorless and with a sweet odor, it doesn’t look scary, but looks deceive.

Why 1-Bromobutane Needs Respect

1-Bromobutane is a liquid alkyl halide used in organic synthesis. In practice, its biggest enemies are light, heat, moisture and air. I learned to never place it near an open window or a heat source. This stuff boils at about 100°C and can evaporate if the lab gets too warm. If you keep it anywhere above room temperature, some of it will end up as vapor in the air. In small spaces, that vapor builds up.

The Right Container and Placement

Glass bottles with tight-sealing screw caps work best. One mistake I saw was keeping bromobutane in a thin plastic container. The chemical softened the plastic, and in a few weeks, the bottle went cloudy. I double-checked material compatibility after that. Polyethylene or polypropylene hold up much better, but glass stands up to almost anything in a typical lab.

Storing this chemical in an amber glass bottle protects it from light, which slows its decomposition. A neat trick some chemists use: wrap the container in aluminum foil for extra protection if the shelf is exposed. Nothing fancy—just practical defense.

What the Guidance Actually Means

Lots of storage recommendations focus on “cool, dry, well-ventilated places.” In daily lab life, I translated that advice into a few rules. Never store bromobutane above eye level; someone might drop it. Stick it in a flammable storage cabinet, away from oxidizers, acids, or bases. Store it with similar chemicals, never next to metals or reactive reagents.

Humidity spells trouble, especially with organic halides. I once saw water droplets inside a poorly capped bottle. That’s a flammable vapor hazard and an explosion risk with the right spark or nearby open flame. I checked caps every week, never skipped it. It’s just a habit that kept the lab running safer.

Labeling Isn’t Bureaucracy—It’s Survival

Labeling bottles isn’t just paperwork. I once fumbled with a faded label—was it dichloromethane or bromobutane? That mistake could ruin an experiment or put people in danger. Every bottle in our group had a date, the exact name (no shorthand), and the person’s initials. If the bottlet’s contents expired or changed color, we flagged and replaced it.

Good Storage Makes for Fewer Accidents

Storing 1-bromobutane isn’t about following rules for rules’ sake. Every bit of care—choosing the right bottle, picking the proper shelf, labeling with exact names—reduces risk. Most spills and lab accidents I saw over the years started with a shortcut. Staying disciplined with storage isn’t just wiser, it means fewer surprises and a safer workspace for everyone.

Getting to Know 1-Bromobutane

As somebody who’s handled 1-Bromobutane in a college lab, you remember its sharp odor and clear, colorless look before you ever glance at the textbook figures. This compound shows up when you add bromine to butane, swapping out a hydrogen for a bromine atom. 1-Bromobutane comes with a straightforward formula, C4H9Br, but even simple molecules like this carry plenty of practical quirks.

What You See and Smell

This chemical pours as a liquid under room conditions—no surprises for those used to working with other straight-chain bromides. The first thing you notice, outside the fume hood, is the strong, sometimes overwhelming, sweetish odor. The color stays transparent, which helps during purity checks. Don’t let anyone catch a whiff without protection, though, since the fumes can leave your head spinning or your eyes tearing up.

How It Handles Temperature

On the matter of temperature, 1-Bromobutane boils at about 101 degrees Celsius. Toss some in a test tube and hit it with a Bunsen burner, and it turns to vapor faster than water but sticks around longer than more volatile lab solvents such as diethyl ether. That quality lets you use it for extractions or reactions where you need a compound that won’t flash off too soon. If you chill it down to -112 degrees Celsius, it’ll freeze solid. Not many everyday folks have call for that, but for precision work, those numbers matter.

Density: Heavier Than Water

From the first drop, you see right away that 1-Bromobutane won’t float. Its density sits at about 1.27 grams per cubic centimeter, making it sink in water. Mix it in a beaker with plain tap water and it settles straight to the bottom. In my experience, this comes in handy when separating layers after a reaction or extraction—especially in crowded student labs where time matters. The weight also hints at that bromine atom packed onto the carbon chain, adding both heft and firepower in chemical reactions.

Solubility and Mixing

Try swirling 1-Bromobutane in water, and you’ll notice stubborn droplets that never really blend. It’s barely soluble in water, thanks to its nonpolar chain and weak attraction for water’s polar nature. Instead, it mixes much better with ether, alcohol, and most organic solvents. This property shapes a lot of hands-on chemistry, where you need an organic phase to pull out products or purify materials after a reaction.

Other Key Physical Features

1-Bromobutane brings some other tricks to the table. Its refractive index, a measure of how much it bends light, sits at 1.4399. That’s higher than pure alkanes, again pointing to bromine’s influence. For the hazard-minded, its vapor carries a bit of danger; its flash point—where vapors can ignite—hovers near 32 degrees Celsius. Keep it far from flames or sparks. The skin and eyes also don’t get along well with this liquid, and even brief exposure calls for goggles and gloves, a rule pounded into my brain by more than one safety officer.

Why These Details Matter in the Real World

These facts might seem dry, but knowing 1-Bromobutane’s physical properties turns out to be your best defense, whether you’re trying to avoid spills, design a separation, or pick it apart in research. Each number comes from years of trial, error, and attention to the habits of molecules in glassware. For people in the lab, keeping these traits in mind doesn’t just save money—it could prevent injuries, save time, or open up more efficient ways to build the next useful compound. Anyone who cares about clean results, safety, and getting the job done right always checks the numbers before uncapping the bottle.