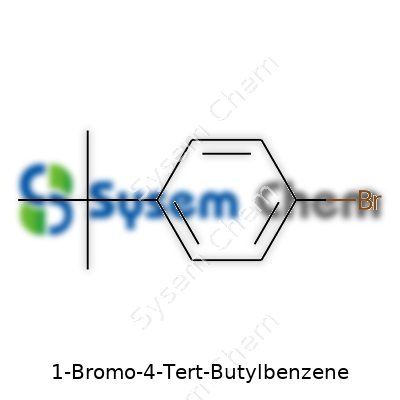

1-Bromo-4-Tert-Butylbenzene: An In-Depth Exploration

Historical Development

Chemists have searched for reliable ways to introduce functional groups onto aromatic rings since the dawn of organic synthesis. Back in the late 19th century, aromatic bromination became a staple technique, opening the door for compounds like 1-Bromo-4-Tert-Butylbenzene. Early forms of this substance found their way into laboratories as research chemists sought molecules that could serve as sturdy stepping stones for making more complex chemicals. The tert-butyl group on the para-position offered a route to stabilize the aromatic system, while the bromine atom added a handy spot for further transformation. Interest grew steadily, particularly through the 20th century, as new methods for manipulating aromatic compounds emerged and demand in industrial chemistry picked up pace.

Product Overview

1-Bromo-4-Tert-Butylbenzene, sometimes known on supplier lists by its compact formula C10H13Br, stands out due to its unique combination of stability and reactivity. Many see this chemical as a prime candidate for use in building more complex organic compounds, both in academia and manufacturing. Its distinct molecular structure features a bromo substituent on a benzene ring positioned opposite a tert-butyl group. In a practical sense, chemists appreciate this setup for facilitating predictable reactivity in cross-coupling reactions and other synthetic procedures. Several laboratories lean on this compound, whether creating pharmaceuticals, specialty materials, or refining advanced catalysts.

Physical & Chemical Properties

Users will notice that 1-Bromo-4-Tert-Butylbenzene shows up as a clear, colorless to pale yellow liquid at room temperature, with a faint, characteristic aromatic odor. By most standards, it has a boiling point hovering around 230-232°C and a melting point near −13°C. Its molecular weight clocks in at about 213.12 g/mol, and it exhibits low solubility in water but mixes freely with common organic solvents like ethanol, chloroform, and ether. The bromine atom on the aromatic ring creates a site for both nucleophilic and electrophilic substitutions, making this molecule a flexible starting material in synthetic schemes. Notably, its tert-butyl group fends off unwanted side reactions, improving selectivity during downstream transformations.

Technical Specifications & Labeling

Product quality for 1-Bromo-4-Tert-Butylbenzene ties closely to attributes like minimum assay purity (usually>98%), controlled moisture content, and clearly indicated storage instructions. Bottles often carry hazard warnings due to the moderate toxicity of aryl bromides. Labels include CAS number 3972-65-4, UN shipping codes where necessary, and batch numbers for traceability. Chemists and safety officers count on this information, minimizing risk and ensuring accurate record-keeping every time a reaction gets underway. Modern supply chains emphasize not only the purity but also transparent documentation, so the user knows exactly what they're handling.

Preparation Method

Synthesis often starts by treating 4-tert-butylbenzene with bromine in the presence of a Lewis acid, such as iron (III) bromide. This approach leverages the electron-donating nature of the tert-butyl group, directing the bromine to the para position on the ring. Operating under mild conditions with careful exclusion of moisture and oxygen allows chemists to minimize side products and maximize yield. Once the reaction runs its course, the mixture typically undergoes extraction and distillation to isolate the product. This method stands the test of time, thanks to its simplicity and reliability in the hands of experienced synthetic chemists.

Chemical Reactions & Modifications

1-Bromo-4-Tert-Butylbenzene serves as a springboard for a host of chemical transformations. The bromine atom can swap out through various coupling reactions—Suzuki, Heck, and Stille routes, to name a few—bridging aromatic units or linking to more elaborate scaffolds. Nucleophilic aromatic substitution, though less favorable due to the deactivating effect of the tert-butyl group, still comes into play under strong enough conditions. The tert-butyl group itself resists most reaction conditions, standing firm against acids and bases. In my own lab experience, the resilience of the tert-butyl group has kept unwanted rearrangements at bay, letting the aromatic bromide shine as a flexible partner in multi-step syntheses.

Synonyms & Product Names

Those searching chemical catalogs for 1-Bromo-4-Tert-Butylbenzene may encounter a range of alternative names. Its IUPAC name cites it as 1-Bromo-4-(tert-butyl)benzene, though entries like p-tert-butylbromobenzene, 4-tert-butylbromobenzene, or simply para-bromotertbutylbenzene reflect the same core structure. Catalog numbers and supplier codes might help cross-reference across different vendors, yet the CAS number remains the most reliable anchor for avoiding confusion.

Safety & Operational Standards

On the safety front, handling 1-Bromo-4-Tert-Butylbenzene comes with well-defined protocols, reflecting the general caution that goes into working with organobromides. Users must work in a fume hood and wear nitrile gloves, as aryl bromides may irritate skin and mucous membranes or trigger allergic responses. Eye protection isn’t optional; small splashes can cause significant discomfort. Storage takes place in cool, dry conditions, away from heat sources and direct sunlight. Waste management follows local regulations for halogenated organics, with spent reagents and washings sent for licensed disposal. Rigid adherence to safety data sheets reflects not only compliance culture but a genuine concern for well-being in shared lab environments.

Application Area

Uses for 1-Bromo-4-Tert-Butylbenzene stretch across several sectors. In pharmaceutical research, teams exploit its bromine-substituted ring in fragment-based drug design, building lead compounds by attaching bioactive groups. Materials scientists apply this building block during the assembly of advanced polymers, where precise branching or cross-linking lays the groundwork for new mechanical properties. Catalysis researchers value this molecule when creating ligands and finely-tuned metal complexes. In teaching settings, educators find this compound useful for introducing undergraduates to aromatic substitution and the logic behind electrophilic additions.

Research & Development

Across R&D divisions, 1-Bromo-4-Tert-Butylbenzene fuels innovation by granting access to a wide array of structural motifs. Its use in palladium-mediated coupling reactions supports the exploration of new functional materials and active pharmaceutical ingredients. Many process chemists tweak standard procedures, improving yields and reducing the volume of hazardous waste, supporting greener chemistry goals. I have noticed how trial-and-error with different catalytic systems using this compound unlocks new synthetic avenues, letting researchers break free from legacy limitations. Emerging automation and data-driven design tools now enable more rapid screening of reaction conditions, with 1-Bromo-4-Tert-Butylbenzene featuring prominently in libraries for structure-activity analysis.

Toxicity Research

Toxicological data for 1-Bromo-4-Tert-Butylbenzene remain somewhat limited, though evidence suggests moderate toxicity common to many aromatic bromides. Acute exposure may lead to irritation, and chronic exposure raises concerns for both skin and respiratory sensitization. Animal studies point to low bioaccumulation potential, yet environmental researchers still monitor its fate in wastewater streams. Advances in computational prediction models could shed more light on long-term impacts, encouraging manufacturers to adopt robust containment measures in high-volume applications.

Future Prospects

Looking ahead, the future of 1-Bromo-4-Tert-Butylbenzene depends on new synthesis technology and growing emphasis on sustainability. Cleaner, catalytic bromination methods and inventive recycling strategies may reduce waste and improve safety. Pharmaceutical researchers continually hunt for efficient ways to add complexity and function to aromatic scaffolds, creating persistent demand for specialized building blocks like this one. As green chemistry principles take hold, companies may lean on bio-based raw materials and minimize the environmental footprint at every stage, further transforming the landscape for aromatic bromides. Through it all, practical experience with 1-Bromo-4-Tert-Butylbenzene keeps reminding chemists how the right balance of stability and reactivity drives progress in both the classroom and the factory floor.

Chemical Purity: More Than a Number on Paper

I’ve seen a fair share of labs and workshops that rely on the foundation of good chemicals. One question always pops up: just how pure is the 1-Bromo-4-Tert-Butylbenzene sitting on the shelf? Purity isn't just a technical detail, it tells you how trustworthy your entire experiment will be. If you’ve been in research, you know that the difference between a 97% and a 99% purity sample can make or break a whole week’s worth of work.

Sellers usually state that their 1-Bromo-4-Tert-Butylbenzene meets high purity standards, often around 98% to 99%. This sounds solid, but that small remaining percentage can throw a wrench into sensitive projects. The reason is simple: impurities react too. In synthesis, unwanted byproducts create headaches for both researchers and industry workers. This shows up particularly in pharma work, where every contaminant could end up changing a medicine’s safety or effectiveness.

Real-World Impact of Impurities

Lab work isn’t cheap. If you buy a kilogram of 1-Bromo-4-Tert-Butylbenzene and a percent or two is something else, you find yourself chasing odd peaks on your chromatograms or wondering why your yields seem stubbornly low. Equipment doesn’t come cheap either, and repeated runs with impure material can lead to clogged columns, ghost peaks, or problems that only an experienced chemist could recognize without days of troubleshooting.

Compare notes with a colleague who works in QC at a pharmaceutical lab. For them, a substance that tests at 98% instead of 99.5% triggers a long line of extra checks and sign-offs. In drug development, companies follow strict guidelines from agencies like the FDA and EMA. These bodies ask for proof—spectroscopy data, HPLC traces, GC-MS reports—that every impurity is accounted for and known to be harmless at those low levels. That means the “missing” percentage has to be identified, not just ignored.

Support for Purity Claims

Most reputable suppliers publish Certificates of Analysis to show evidence for their claims. Without this documentation, buying bulk chemicals becomes a gamble. Certificates lay out detected impurities, batch specifics, and sometimes stability data. They provide peace of mind that someone checked and logged what came out of the reactor. Over my years of purchasing, I’ve learned to never skip reading these. If a supplier can’t send a clear certificate, it’s worth walking away. This is part of practicing good risk management, which gets a nod from industry standards and regulatory guides alike.

High purity comes from careful process control and smart design in chemical manufacturing. That means skilled workers and decent raw materials. Sometimes, the extra cost of highly pure material is money well spent when a contaminated batch wipes out not just time, but reputation. The natural temptation is to go for a bargain, but the hidden cost comes later when you retrace steps, dispose of wasted product, or try to salvage results.

Improving Confidence in Purity

Better purity starts with choosing suppliers who invest in their product. Third-party lab testing adds another layer of reliability. I like to see data that goes beyond the bare minimum—full chromatograms, NMR numbers, or documented impurity profiles. Asking tough questions up front, or running a small batch test yourself, can prevent serious issues down the line. Auditing suppliers or requesting detailed traceability reports can weed out companies that cut corners.

Researchers and manufacturers pay close attention to what’s in their bottles for good reason. The value of high-purity 1-Bromo-4-Tert-Butylbenzene isn’t just about clean numbers, it’s about protecting results, budgets, and safety. That’s why the simple answer “it’s more than 98% pure” never covers the whole story—demanding proof and understanding what’s in the bottle is what really keeps science moving forward.

Understanding the Nature of 1-Bromo-4-Tert-Butylbenzene

1-Bromo-4-tert-butylbenzene comes up a lot in chemical labs that handle organic syntheses. This compound, a brominated aromatic, doesn’t seem glamorous, but treating it right in storage helps ensure both safety and project success. I’ve seen what happens when basic storage rules are ignored: leaky bottles, strange odors drifting through shared spaces, stressed-out researchers who can’t get reliable results.

Shielding from Light and Heat

Direct sunlight and high temperatures change so many chemicals, and 1-Bromo-4-tert-butylbenzene is no exception. Bright light can sometimes kick off reactions that leave you with new byproducts instead of your needed reagent. Excess heat has made our reagents clump, discolor, or even develop pressure in sealed containers. I recommend keeping this compound in a cool, shady spot, ideally in a chemical storage cabinet away from sources like radiators or windows. Based on manufacturer labels, most labs in North America keep 1-Bromo-4-tert-butylbenzene around 15–25°C, but lower temperatures in a refrigerator (never a freezer) slow down decomposition for longer-term storage.

Avoiding Moisture and Air Exposure

Brominated aromatics can suffer from moisture. Once a bottle sits unsealed in a humid room, labels start peeling and before long, you may notice odd textures at the cap. This compound resists water better than some, but introducing moisture or air often enough can still lead to hydrolysis and contamination. Screw caps tightly and choose containers made of glass—never metal—because halogenated organics can sometimes corrode metals. Some chemists swap the air in the bottle for nitrogen. It’s a time-proven trick to boost shelf stability, although for short usage windows, tightly sealed glass does the job.

Mindful Segregation: Safety Considerations

Most labs sort brominated aromatics away from acids, bases, and strong oxidizers. Storing 1-Bromo-4-tert-butylbenzene next to concentrated acids raises the risk of unstable reactions, especially if there’s a spill. I’ve watched beginners shelve everything alphabetically, but segregation by hazard class keeps accidents at bay. Safety Data Sheets (SDSs) lay this out clearly. If you share a workspace, label each chemical clearly and date it upon arrival. Tidy, segregated shelves don’t just help with compliance—they make for a safer, more predictable lab day.

Labeling, Inspections, and Inventory

Every bottle in our stockroom wears a typed label and the receive date. I’ve relied on this many times to spot expired or questionable reagents before running important reactions. Labs that inspect chemicals monthly, checking for signs of leaks or color changes, avoid headaches caused by degraded stock. Cleaning spills immediately blocks cross-contamination—something that once ruined three days of my team’s efforts after a slow, unnoticed leak. Prompt reporting and disposal of spent chemicals head off environmental harm and keep storage areas within strict legal limits.

Responsible Disposal

Getting rid of brominated compounds demands respect for both legal and environmental rules. These aren’t drain-safe. Partnering with certified waste handlers, using special collection containers, and logging every outgoing chemical brings peace of mind. Many labs now employ small waste containers just for halogenated solvents and reagents, a move that’s made end-of-year cleanouts far less stressful.

Why Good Storage Pays Off

Walking into a well-organized stockroom sets a tone of care and professionalism. It means you can grab 1-Bromo-4-tert-butylbenzene, trust it’s unspoiled, and focus on your experiment, not the shelf behind it. By protecting against light, heat, moisture, and accidental mixing, you safeguard both research quality and everyone’s health. That’s a payoff you notice every working day.

Pulling Numbers from the Periodic Table

Every chemist I’ve known keeps a tight grip on the periodic table, especially for number crunching. Figuring out the molecular weight of something like 1-Bromo-4-Tert-Butylbenzene isn’t just a classroom exercise. It matters. We’re looking at a molecule made of carbon, hydrogen, and bromine. To get its molecular weight, you add up the weights: Carbon (C) comes in at 12.01, hydrogen (H) at 1.01, and bromine (Br) stands hard at 79.90. This compound packs a total of 10 carbons, 13 hydrogens, and one bromine. Multiply and add these, and you end up at around 227.12 grams per mole.

Why Molecular Weight Matters Beyond the Lab

I’ve seen more than a few eyes glaze over at the term “molecular weight,” but in real-world chemistry, it saves time and money. In pharmaceuticals, a single miscalculation can mean bad results—or wasted batches. In the lab, getting that weight right means efficiency. You know how much of each chemical to work with, and surprises don’t show up in your final product. I’ve prepared many reactions where the difference of one digit meant cleanup, recalculations, or having to order more stock.

Balancing Budgets and Safety

Talking about 1-Bromo-4-Tert-Butylbenzene’s molecular weight connects straight to cost and safety. Handling bromine means knowing exactly what’s in your flask. Underestimating it isn’t a simple mistake; it invites risk. Lab accidents often trace back to bad math. One misstep in measurement, and the bill can skyrocket, not to mention downtime from needing extra safety checks when something doesn't add up.

Next Steps for Students and New Researchers

Precision matters. If you’re new or returning to the lab, always crosscheck your numbers. A well-maintained reference notebook will streamline later projects. The formula for 1-Bromo-4-Tert-Butylbenzene becomes muscle memory. Capping each project with a clear calculation keeps processes smooth—and trusted.

Tools and Resources Make a Difference

Online calculators help, but there’s no substitute for learning direct calculation by hand. I’ve seen more mistakes slip through slick apps than through a careful double-check. Don’t depend only on software. Digital resources, such as PubChem and ChemSpider, offer quick access to compound data, but always recheck values for the compound you’re studying. Small errors slip through, especially in user-generated content.

Building a Foundation for Advanced Research

Accurate molecular weights offer more than nice trivia. They pave the way for scalable research. In my experience, robust research starts with solid fundamentals. Graduate students and industry scientists alike use these values for everything from new drug synthesis to materials science. Start sloppy, and the whole chain wobbles.

Consistency Leads to Credibility

Real trust in science grows from consistent, repeatable results. Nailing the weight of 1-Bromo-4-Tert-Butylbenzene every step of the way doesn’t just pass muster inside one lab. It sets expectations for anyone reviewing results, from regulatory boards to publishing journals. In a career spanning academic labs and industry settings, meticulous weighing and calculation built every good reputation I’ve heard of.

A Compound With Real Chemical Muscle

1-Bromo-4-tert-butylbenzene shows up in labs that build custom molecules, brew new polymers, or tweak pharmaceuticals. Its structure looks simple, yet its value pops up in reactions where a bromine handshake opens the door for all kinds of further chemistry. Chemists searching for efficient tools run into this compound because it slides right into Suzuki couplings, Grignard reactions, and other backbone-forming steps.

Bulk Supply: A Real Challenge

Getting a few grams for research rarely causes a stir. Most big-name chemical suppliers list it in standard catalogs, and any research group with a credit card and a delivery address wraps up a bottle quickly. That door slams most of the time once you start asking about bulk—think kilos, not grams. What changes at this scale?

Production steps up in complexity as orders grow. Suppliers pay attention to environmental and safety regulations, especially because brominated compounds can trigger extra scrutiny. Manufacturing routes focus on yields, purity, and handling the byproducts, including ones nobody wants going anywhere near the sewers or landfill. Not every facility handles this complexity; companies with the right expertise can meet larger orders, but prices and lead times reflect real work behind the scenes.

Who’s Buying in Bulk, and Why?

Small drug firms, specialty material outfits, and contract manufacturing organizations request 1-Bromo-4-tert-butylbenzene at scale. I’ve worked in research operations where teams hit a bottleneck waiting weeks, sometimes months, for specialty building blocks. A delay in securing a few kilos can derail an entire project timeline.

Nobody takes the plunge to scale unless there’s a concrete project. Big pharma doesn’t stock this compound like aspirin—demand spikes happen when a process route standardizes on this building block or a development batch heads to the pilot plant. Startups and academic spin-outs—often working with tight capital—can see the cost per kilo hit hard, sometimes climbing three or four times compared to smaller quantities due to special shipping, handling, and certification needs.

Reliable Sourcing—What Works?

It pays to dig past the first few hits on Google. International vendors, especially in the US, Germany, Japan, and India, claim bulk capabilities, but the fine print matters: purity specs, batch-to-batch consistency, and real lead times. Trade shows and industry contacts often lead to trustworthy suppliers—relationships built over years still matter.

Regulatory paperwork slows things down. If the product is heading into anything near a regulated industry—pharma, especially—the supplier must show traceability, lot documentation, and sometimes meet specific GMP requirements. I’ve watched fledgling med-tech companies pivot mid-project after a source failed to deliver a paper trail matching regulatory expectations.

Pushing Forward: Solutions for Short Supply

Domestic chemical manufacturing can regain ground by simplifying import processes and supporting responsible scale-up. Suppliers who invest in regional production bring quicker response times and stronger quality control. Local universities and industry labs should find ways to team up with suppliers, since feedback from real experiments sheds light on batch variability issues and forecasting demand. That tight feedback loop can help both sides avoid costly surprises.

In the meantime, companies planning for scale do well to lock contracts early, double-check certifications upfront, and maintain plan B sources. Chemistry might run on molecules, but delivery still rests on relationships and clear communication every step of the way.

Where Chemistry Meets Real Innovation

I’ve seen a lot of niche chemicals claim a spot on the shelves of research labs, but few have earned such a reputation in synthetic chemistry circles as 1-Bromo-4-tert-butylbenzene. Its long name hides a rather practical utility in the world of organic synthesis. Just one look at the structure, and chemists spot that bromo group waiting to take part in cross-coupling reactions. That tert-butyl piece, sticking out like a shield, brings both stability and some interesting selectivity to the game.

Key Roles in Pharmaceutical Research

I’ve met research teams using 1-Bromo-4-tert-butylbenzene in the early stages of drug discovery. For them, it isn’t just a building block; it opens paths to molecules that would be hard to reach otherwise. The bromo group joins forces with palladium catalysts in Suzuki, Heck, or Sonogashira couplings. These reactions lay the foundation for much of today’s pharmaceutical innovation. Tinkering with the tert-butyl group often makes molecules harder for metabolic enzymes to break down, an essential trait for designing medicines that last long enough in the human body to be effective. According to a review in ScienceDirect, these types of aryl bromides help create candidate drugs that pharmaceutical pipelines need for clinical trials.

Moving Beyond Medicines: Material Science Applications

Chemists don’t just stop with health sciences. Material science also leans on clever building blocks, and this compound fits the bill. Custom-designed polymers and advanced plastics owe some of their tailored properties to building blocks like 1-Bromo-4-tert-butylbenzene. That tough tert-butyl group adds bulk to polymer chains, lowering crystallinity and changing melting behavior. These shifts can make plastics more flexible or improve their ability to handle temperature swings.

Specialty Ligands and Catalysts

It’s impossible to ignore how often chemistry teams use molecules like this as starting points for ligands and new catalysts. The tert-butyl group creates spatial effects in metal complexes—making new catalysts that speed up tricky reactions. Research groups worldwide keep reporting new catalysts relying on aryl bromides just like this one, according to journals like the Journal of Organic Chemistry.

Safety and Environmental Considerations

Handling 1-Bromo-4-tert-butylbenzene calls for some respect. Like most brominated organics, it can cause skin irritation and needs careful storage. Companies focusing on green chemistry look for ways to reduce waste and recycle halogenated solvents. Tools like microflow reactors have started to cut solvent use and improve overall safety.

What’s Next: Smarter Synthesis and Sustainability

Sustainability challenges can’t be ignored in today’s labs. With tighter regulations on brominated waste and pressure to use renewables, chemists look for alternatives. Biobased feedstocks, better waste treatment, and innovative catalysis lend hope. Companies partnering with academic labs push toward less hazardous, more efficient routes involving brominated arenes.

From the labs hunting for tomorrow’s blockbuster drug to the factories spinning out new materials, the importance of 1-Bromo-4-tert-butylbenzene runs deep. For anyone stepping into organic synthesis, it stands as a reminder of how the right chemical tools can shape entire industries, always nudging researchers to think hard about both performance and responsibility.