1,6-Dichlorohexane: Insights, Challenges, and the Road Ahead

Historical Development

The story of 1,6-dichlorohexane stretches back to a time when chemists scoured the landscape of organic synthesis to meet the demands of plastic and polymer industries. By the mid-20th century, demand for versatile intermediates that could deliver both reactivity and selectivity set off a wave of research. Chemists eyed dihalogenated alkanes like 1,6-dichlorohexane for their knack in introducing controlled molecular connectivity. Europe and the United States spent resources to meet industrial and military needs, especially as synthetic rubbers and specialty plastics marched into mainstream production. Over the decades, as regulations tightened, researchers honed purification processes and routes to full-scale manufacturing to produce a reliable product, minimizing contaminants like polychlorinated byproducts.

Product Overview

Industry classifies 1,6-dichlorohexane as a specialty dihalide, sought for its six-carbon backbone and terminal chlorine atoms. This configuration puts it in a unique class of molecular building blocks that find use from pharmaceuticals to specialty materials. In my experience, bulk suppliers often sell it in steel drums or high-density polyethylene containers, ready for downstream processing. It enjoys a steady market in the fine chemical and polymer fields, and customers usually watch for moisture content and purity to keep downstream reactions on track.

Physical and Chemical Properties

1,6-dichlorohexane comes as a clear, colorless liquid with a faint, chloroalkane-style odor—few would call it pleasant. Its boiling point usually lands near 225°C, so it handles lab distillation without fuss. Density sits slightly above water at around 1.07 g/cm3. It doesn’t mix well with water, but goes easily into organic solvents such as ether, acetone, and benzene. On the chemical side, the two terminal chloro groups serve as molecular anchors for nucleophilic substitution, letting chemists install new groups on either or both ends. The molecule itself tends to sit quietly at room temperature but jumps into action with the right catalyst or base.

Technical Specifications & Labeling

Each barrel or flask comes stamped with purity, batch number, and shelf-life. Labs look for specifications like GC purity above 98%, water content below 0.5%, and color standards measured by Hazen scale. Packaging usually demands moisture barriers and warnings to handle with care, since improper storage can corrode seals or introduce unwanted hydrolysis. EU and US regulations push for harmonized Safety Data Sheets, ensuring users recognize both product quality and inherent risks.

Preparation Method

Several routes lead to 1,6-dichlorohexane, though chlorination of hexane-1,6-diol or direct chlorination of n-hexane with controlled conditions dominate. Manufacturers fine-tune reaction temperature and the ratio of starting materials. Side products—like higher-chlorinated hexanes or incomplete substitution—stay under strict watch, since downstream processes depend on high selectivity. Purification by distillation under reduced pressure removes thermal risks, and care during storage avoids unwanted light or heat exposure. Researchers always watch for traces of unwanted diols or mono-chlorohexanes sneaking through, as they can gum up later syntheses.

Chemical Reactions and Modifications

1,6-dichlorohexane shines as a bridge between disparate chemical species. It eagerly surrenders its chlorines under basic or nucleophilic conditions, letting chemists craft elaborate structures such as macrocycles, crown ethers, or straight-chain polyamides. I’ve seen it act as a handy cross-linker in polycondensation—where striking the right molar ratio gives tight control over molecular weight. The molecule can also serve as a backbone for introducing azides, thiols, or organometallics, which then open doors to new material classes. Reactions must balance speed with selectivity, because side products waste precious starting material and complicate purification.

Synonyms and Product Names

Across SDS sheets, suppliers swap between “hexamethylene dichloride,” “1,6-dichloro-n-hexane,” and simple “DCH.” Trade names avoid confusion by marrying the core name with supplier branding. In research and patents, hexamethylene dichloride crops up most often, especially in polymer and specialty chemical documents. Database searches need a steady hand, as variants in hyphenation or prefix can shift search results—a detail that has tripped up more than one materials scientist.

Safety and Operational Standards

Working with 1,6-dichlorohexane demands a disciplined approach. Its vapors can irritate the eyes, nose, and throat. Gloves and splash goggles stay on during handling, and chemical fume hoods cut exposure risk. Spills call for absorbents and proper disposal—this isn’t something you mop up and forget. Fire safety stands front and center, since the liquid can form toxic hydrogen chloride fumes on burning. European REACH and American OSHA frameworks both call for strict labeling, proof of worker training, and robust spill response. In my experience, plant operators run annual drills to keep teams sharp.

Application Area

Industries reach for 1,6-dichlorohexane as a linker and intermediate. Nylon-6,6 production, polyurethane research, and specialty elastomers all owe something to this molecule. Fine chemical synthesis uses it for chain extension, while pharmaceutical research turns to it for easy installation of custom groups or pharmacophores. Surface modification and coatings benefit from its terminal chlorines, which add stickiness or create cross-linked meshes. In my own lab days, we tapped it as a spacer for enzyme immobilization on solid supports, which needed both reactivity and separation between catalytic sites. Its unique length and terminal reactivity lend flexibility, but its toxicity narrows the range of open-hand uses.

Research and Development

Cutting-edge research cares about selectivity and greenness. Newer synthetic methods try to dodge classical chlorination by leaning on flow chemistry or photochemical activation, which cut undesired byproducts and increase atom efficiency. Researchers dig into catalytic approaches for both making and breaking the carbon-chlorine bonds, unlocking new late-stage modifications. In applied fields, polymer scientists play with incorporating 1,6-dichlorohexane into novel polyamides and responsive materials, aiming for a sweet spot of mechanical strength and processability. Environmental chemists, meanwhile, probe pathways for safe degradation and cleanup. Peer-reviewed journals bristle with protocols to minimize waste, recovery, and risk of persistent byproducts.

Toxicity Research

Toxicologists keep a close eye on chloroalkanes, and 1,6-dichlorohexane is no exception. Animal studies flag it as a potential irritant with moderate acute toxicity, especially at higher doses or prolonged exposure. Chronic exposure could impact liver enzyme levels, but researchers lack longitudinal human studies that clarify the risk. Regulatory bodies frequently update exposure limits and acceptable daily intakes as more animal data comes to light. In industrial settings, air monitoring and personal protective equipment matter more than ever. The push for alternatives sometimes runs up against performance trade-offs, so thorough risk assessment remains key. Academic and commercial labs work to design analogues with less persistence or lower uptake in living tissue, but replacing legacy intermediates in entrenched processes tends to move slowly.

Future Prospects

The future of 1,6-dichlorohexane feels tied to three forces: regulatory tightening, greener synthesis, and the shifting needs of specialty materials. As international agreements keep squeezing down on chlorinated organics, manufacturers invest in less resource-intensive production and cutting-edge waste treatment. The rise of bio-based polymers and biodegradable alternatives challenges its market share, but industries hooked on custom reactivity keep the dial turned up for high-purity supplies. Startups and academic groups race to develop methods that blend classic reliability with modern sustainability goals. There’s a growing push to study long-term effects on ecosystems and human health, aiming for transparency and public trust. Open collaboration between regulators, researchers, and producers holds promise for managing risks without stifling genuine innovation.

Why Knowing the Formula Matters

Every high school chemistry student remembers the struggle of memorizing chemical formulas, but those strings of letters and numbers do more than fill exam sheets. They open a window into the world behind the beakers and vials: the interactions, risks, and opportunities present in every compound. Looking at 1,6-dichlorohexane, for those dealing with organic synthesis, this information can shortcut research or prevent costly mistakes.

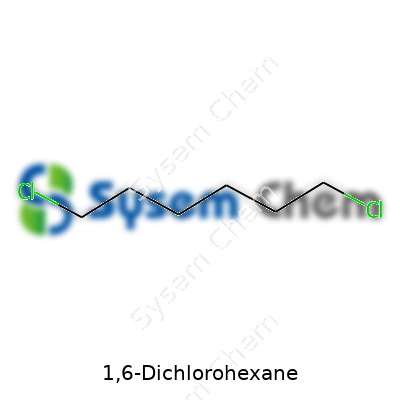

The Formula Unpacked

1,6-Dichlorohexane has the chemical formula C6H12Cl2. This structure tells a story. Start with six carbons in a chain – hexane forms the backbone. Swap out a hydrogen on each end for chlorine, and you end up with something new: 1,6-dichlorohexane.

C6H12Cl2 might look modest, but quite a bit happens at the molecular level. Chlorine atoms sitting on the ends change how the molecule behaves. Now, the compound can take part in interesting reactions. For those creating specialty polymers or testing new chemical pathways, this isn’t just trivia. It’s the starting gun for a dozen types of experiments.

Digging Into Its Uses

In industrial labs, 1,6-dichlorohexane helps create building blocks for things like nylon. Anyone who’s ever patched a torn tent or watched athletes sprint across the turf has seen the results of these long carbon chains up close. Its formula tells manufacturing engineers exactly what they need to mix, handle, or neutralize in the setup.

Anyone with a background in lab work knows that the formula isn’t just theoretical. If one hydrogen goes missing, or a chlorine shifts to the wrong position, processes might stall or release something toxic. The specificity of C6H12Cl2 is a safety net and a recipe.

Health and Environmental Impact

Not every compound with chlorine is friendly to humans or the environment. 1,6-dichlorohexane finds its way into the conversation about chemical safety training because chlorinated hydrocarbons sometimes resist easy breakdown. Several government guidelines flag these molecules, urging factories and supply chains to store and dispose of them properly. Unintentional releases into soil or water raise red flags for inspectors and environmental consultants.

Many labs run strict protocols because exposure can irritate the respiratory tract or skin. Regulatory agencies suggest containment, monitoring, and protective gear – not only because of the risks, but also to meet compliance for chemical handling and disposal.

Moving Toward Safer Practices

Chemistry isn’t all trial and error anymore. It leans on shared data, careful observation, and transparency about risks. Any process involving 1,6-dichlorohexane needs routine assessments, seeking ways to substitute safer chemicals or install smarter waste treatment. Those approaches lower the odds of accidents, keep workers healthier, and shrink the environmental footprint.

C6H12Cl2 sits at a crossroads of utility and responsibility. Studying the formula and its implications signals respect for both science and safety — a foundation that outweighs any shortcut or oversight in the lab.

Introduction to 1,6-Dichlorohexane

1,6-Dichlorohexane turns up in labs and factories far more often than most folks realize. With its two chlorine atoms spaced along a six-carbon chain, this compound acts as a key building block for a range of chemicals. Most people never handle it directly, but the products built from it end up in surprising places.

Role in Polymer Production

Walk through any plastics manufacturing plant: odds are good you’ll see 1,6-Dichlorohexane at work. Chemists use it to create specialized nylons and polyamides. Take nylon-6,6, used in fibers for making clothing, ropes, and industrial materials. The dichlorohexane helps form the core of these tough synthetic chains. Its reactivity, especially with amines, wins over manufacturers because it leads to strong, durable materials with repeatable results.

A chemist I knew from my days around university research liked to talk about polymer “building blocks” the way a chef talks about flour or eggs. 1,6-Dichlorohexane acts much the same for polymers: a reliable ingredient that keeps large-scale processes moving predictably. It’s not glamorous, but without it, nylon production would grind to a halt.

Intermediate in Pharmaceutical Synthesis

Drug companies need chlorine-bearing intermediates, since they often help change molecular shape or introduce new chemical groups. 1,6-Dichlorohexane helps make certain antihistamines, antifungals, and other pharmaceuticals. It’s not the star of the final product, but it sets up molecules to deliver results in the patient’s body. Researchers lean on its chemical structure to add length to a carbon chain, or to serve as a spacer that keeps more complicated parts of a molecule properly positioned.

Safety matters in any pharma lab, and handling chlorinated solvents gets lots of attention. Nobody wants accidental exposure, so fume hoods, gloves, and strict inventory practices stay in place. Proper storage away from heat or flame stands as a given — companies focus on both worker safety and end-use purity. Mistakes with chlorinated solvents historically caused health issues; over time, improved protocols brought down risks.

Crosslinking Agent in Specialty Chemicals

Epoxy resins and adhesives gain strength and flexibility by linking polymers together. 1,6-Dichlorohexane brings value here as a crosslinker. The chemical bridges between two long plastic chains, boosting properties like elasticity and heat resistance. Paint producers and adhesive makers find this useful when tailoring products to withstand tough environments.

I once visited a plant that made industrial sealants — these jobs depend on meticulous recipe work. Operators check batch sheets closely, since a mix-up with ingredients disrupts curing, strength, and final performance. 1,6-Dichlorohexane’s predictability in these systems lets companies minimize waste and keep products dependable.

Environmental and Health Considerations

Any use of chlorinated organics will raise concerns. 1,6-Dichlorohexane poses risks if inhaled or mishandled. Over time, tighter legal rules pushed chemical companies to reduce emissions and invest in closed-processing equipment. Modern labs recover solvents and track usage down to the gram. Disposal plans avoid dumping into water supplies and ensure incineration at facilities meant for hazardous waste.

Safer alternatives pop up in industry journals, but none match the balance of cost and chemical function in every application. Until better options arrive, careful oversight and new engineering controls will keep workers and communities as safe as possible.

Paving the Way for the Future

Science never stays still. Manufacturers and researchers watch out for greener, safer replacements, both to meet laws and customer preference. In the meantime, 1,6-Dichlorohexane stays indispensable for making plastics, drugs, and specialty glues. Success depends on vigilance—good chemistry, safe practice, and a willingness to improve as new ideas take shape.

Understanding the Risks

1,6-Dichlorohexane doesn’t get much press, but those who work in labs and factories know it by reputation—a clear liquid, not too different from many others at first glance, but with some real bite beneath the surface. Breathing in vapor or getting it on your skin can mean headaches, rashes, or more serious troubles for organs if exposure piles up. There’s always a temptation to move fast and skip the gloves or mask, but this is not a shortcut with a safe ending.

PPE: Non-Negotiable Gear

Gloves made from nitrile or neoprene put a barrier between skin and chemical, stopping the burn before it starts. Throwing on a pair of old latex gloves from a dusty box may seem like “just fine for a quick pour”—my younger self learned the hard way. I developed irritation along my wrists after handling a similar chlorinated solvent because I cut corners on glove choice. Now, I pick gloves rated by manufacturers for these tricky compounds and make sure the cuffs overlap the sleeves of my lab coat.

Splashing, even a single drop, can get in your eyes. Safety goggles or, even better, a face shield goes a long way to keep the day uneventful. Any work in small or confined spaces calls for real ventilation—turn on the fume hood, double-check the airflow, and watch for any funny smells or stinging eyes that signal a problem.

Ventilation and Housekeeping

A flammable solvent like this one doesn’t get along with open flames or even sparks. No smoking signs shouldn’t just hang as reminders—they actually belong. Clearing away clutter, wiping surfaces after every session, and emptying waste containers regularly doesn't only help keep things tidy. It cuts down on accidents—spills go unnoticed in a messy space and vapor builds up if air isn’t moving. Years living near a chemical plant taught me that most major incidents start with ordinary neglect.

I remember a friend who learned about vapor density the wrong way—he was working one floor below a chemical spill, unaware that heavier-than-air vapors like those from 1,6-Dichlorohexane were creeping down the stairs. Luckily, someone upstairs heard coughing and hit the alarm. This sort of solvent sinks, so open those lower-level windows and doors and run the exhaust fans at floor level.

Storage and Spills

Locking storage cabinets, labeled for flammables, keep minds at ease. Glass or high-density polyethylene containers do the trick, tightly capped, no exceptions. If a spill finds its way onto a bench or the floor, reaching for the sand or absorbent pads beats paper towels or rags—never seen paper stand up against chlorinated chemicals without coming apart and spreading the mess.

Having material safety data sheets (MSDS) nearby, not just filed away, helps in urgent situations. Reading about cleanup protocols and understanding the right steps before trouble starts can change the outcome of a bad day.

Emergency Routines

We practiced emergency drills at my old job monthly. Ensure that eye wash stations and safety showers are easy to reach, tested weekly, and free from boxes or mop buckets blocking the way. No one expects an accident until it happens; that’s why walking the escape route and double-checking shelves for leaks and drips feels tedious, but beats panic hands down.

Trust comes from knowing those around you are equally prepared and committed. Treat every work session with 1,6-Dichlorohexane as a team effort—remind each other, check the gear, keep the space clear, and nobody has to worry about being the next cautionary tale.

Why Proper Storage Matters

I’ve worked in labs where 1,6-Dichlorohexane was among the dozens of bottles lining the chemical shelves. Nobody needed a reminder that storing chemicals the right way is both a safety issue and a requirement for quality control. One wrong step could put people at risk, damage property, or cost a fortune in lost materials. With 1,6-Dichlorohexane, the risks grow because of its volatility and potential health effects, which range from skin irritation to respiratory issues on exposure.

Keep It Cool, Keep It Safe

From my own experience, this is not the type of chemical you want getting warm in direct sunlight or next to a heater. Heat can lead to pressure build-up inside the container, possibly causing leaks or—worst case—a rupture. Always aim for a cool, dry place, away from sources of heat. Commercial storage rooms with climate control systems often work best, but even basic shelving in a dedicated chemical storeroom does the job if it maintains steady, low temperatures. Room temperature sometimes gets tossed around as a standard, but for volatile organics, even slightly cooler conditions help slow down any unwanted reactions.

Focus on Ventilation and Segregation

I remember a case where air in a poorly ventilated storage closet got thick with fumes. Chemicals like 1,6-Dichlorohexane release vapors that should never build up—not just because of the smell, but because inhalation is a serious health hazard. Good ventilation keeps the air clean. Fume hoods or exhaust systems belong in any room handling this substance. Storage needs to keep the chemical away from oxidizers and strong acids. It tends to react badly when mixed with incompatible materials, creating dangerous byproducts or heat. Reading the label and safety data sheet gives real, practical information on what should not live next to this bottle.

Containers: Strong, Secure, and Stable

Glass or high-density polyethylene bottles perform well for this type of solvent. During one of my years handling bulk shipments, I saw flimsy containers fail because the solvent chewed through the plastic. Every vendor worth buying from will supply it in something that can stand up to long-term contact. The cap plays a crucial role. A tight seal avoids leaks and keeps fumes from sneaking out. Even so, storing the bottle inside a secondary containment bin prevents spills from spreading if an accident occurs. This tactic saved us hours of cleanup after an earthquake shook things loose once.

Clear Labeling, Zero Confusion

Labels sound like a minor detail—until someone grabs the wrong thing in a rush. Every bottle should carry a clear, legible name, concentration, and hazard warnings. Writing the date of receipt and opening helps manage shelf-life; solvents like this lose their edge over time or through contaminant exposure. Avoid decanting into unlabeled jars or containers. Every broken rule here drove home how confusion only adds to risk.

People Make the Difference

Good training and regular reminders often do more to prevent accidents than any single piece of equipment. Newcomers sometimes assume all clear liquids behave the same. Sharing real stories and hands-on demonstrations turns safe storage from theory into habit. Keeping a master list of hazardous chemicals and their locations helps in case of emergencies and inspections alike.

Better Solutions: Technology and Communication

Today’s labs use digital inventory systems and barcodes for tracking. Knowing exactly how much stock sits on shelves, and where, keeps over-ordering and crowding to a minimum. Taking time to review storage policies each year, especially after an incident or near miss, definitely pays off. It shows real commitment to safety and quality.

Chemicals in Daily Life: Why 1,6-Dichlorohexane Matters

Shoppers rarely stop to read ingredients on a bottle of cleaner, and most people never hear about intermediates like 1,6-dichlorohexane. Yet, those in the chemical industry, research, or manufacturing world come across this substance far more often. It’s a chlorinated hydrocarbon used as an intermediate in plastics, rubbers, and specialty chemicals. Plenty of labs and factories keep 1,6-dichlorohexane on hand, but conversations about safety often focus on big, headline chemicals like BPA or PFAS. True safety requires looking at every link in the supply chain, even the obscure ones.

Health Hazards Come From Exposure

People seldom touch 1,6-dichlorohexane directly in daily consumer use, but those working in plants or transportation do encounter risk. Its vapors, skin contact, and accidental spills all carry baggage. Breathing in this chemical often causes throat and lung irritation. Chronic contact brings headaches, dizziness, and skin irritation, sometimes even more severe issues after long periods. Reports from occupational health studies suggest chlorinated hydrocarbons can sometimes affect the central nervous system and cause damage over years of exposure.

Personal experience with handling strong chemicals goes back to years spent working in research. Even brief carelessness—opening a bottle without a fume hood—brought quick discomfort. Tingling fingers, tickle in the throat, or sudden headaches didn’t take much exposure. Regulations urge gloves, goggles, and good ventilation, and these truly make a difference. It’s not paranoia; it’s the reason people in labs and industry environments take protocols so seriously.

Environmental Effects Reach Farther Than Expected

Disposal presents another major challenge. Dumping even small amounts of chlorinated solvents can seep into groundwater or soil. Research shows that these substances resist natural breakdown in the environment. Chlorinated hydrocarbons, which include 1,6-dichlorohexane, can linger for years, turning up in water samples far from where they started. Fish and animals suffer when they take up chemicals that don’t belong in their ecosystem. Some studies indicate that breakdown products might be even more toxic than the original compound.

Having grown up near chemical plants, I’ve seen what mishandled substances can do to rivers and fields. Local fishing spots shut down from contamination; folks worry about their well water. Accumulated mistakes with small chemicals add up over decades. Years later, cleanup projects still struggle to reverse the damage.

Solutions Start With Responsibility

Solvents and intermediates don’t need to be villains, but careful use and disposal are non-negotiable. Companies must give workers proper protective gear, air-quality monitoring, and training—and back these up with active enforcement. Local agencies should keep a close eye on disposal and support better wastewater filtering. Researchers hunting for greener alternatives play a vital role here; every new synthesis route that skips chlorine helps reduce future risk.

On the policy side, tighter reporting, tougher rules on waste, and expanded workplace monitoring hold the greatest promise. Decision-makers shouldn’t ignore the “small” chemicals. When each link in the chain is safe, entire industries—along with the people and places around them—run with a lot less risk.