1,6-Dibromohexane: A Down-to-Earth Analysis

Historical Development

Science never gives up its search for new molecules that change how we build things. In the chemical world, 1,6-dibromohexane has earned its stripes over the decades, mostly because of a simple backbone that offers plenty of room for creative work. Chemists first started exploring the dibromoalkanes during a time when brominated hydrocarbons were getting attention for their usefulness in organic synthesis and polymer production. 1,6-Dibromohexane, which offers a spaced-out bromo handle on both ends, found respect in the laboratories just as research in synthetic polymers and pharmaceuticals started taking off. It unlocked new ways to join and extend carbon chains, leading to ideas and products we still see in research and industry today.

Product Overview

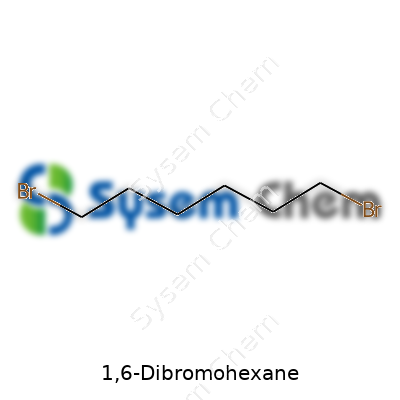

Ask anyone who’s worked in a university or industry lab, and there’s a good chance they’ve handled a bottle of 1,6-dibromohexane. With its two bromine atoms sitting on the end of a six-carbon chain, the molecule packs just enough punch to make itself useful without creating too many headaches in the process. Manufacturers have learned how to deliver it reliably, paying close attention to purity because impurities always seem to pop up when least expected in synthetic work. The chemical’s physical form—a clear, slightly viscous liquid—makes it easy to measure and dispense, unlike some solids that always seem to spill or stick to the scoop.

Physical & Chemical Properties

1,6-Dibromohexane carries a molecular weight around 271 g/mol. At standard conditions, it shows up as a colorless to pale yellow liquid. It doesn’t evaporate nearly as fast as familiar solvents like acetone, thanks to its relatively high boiling point near 255°C and melting point around -10°C. Density clocks in around 1.51 g/mL, letting you know there’s plenty of bromine in the mix. It dissolves well in a range of organic solvents but won’t budge in water, not surprising for a long-chain alkyl dibromide. Because of the two bromine atoms, the compound is reactive enough for alkylation work but doesn’t go overboard and start breaking down under room conditions. This balance keeps it popular in custom syntheses.

Technical Specifications & Labeling

Reputable suppliers mark their bottles clearly with CAS number 629-03-8, along with molecular structure diagrams and hazard labeling. The technical sheets usually spell out minimum purity—often 98% or greater—and detail common contaminants such as related alkanes or trace water, both of which affect product performance in delicate reactions. Packaging ranges from small amber glass bottles ideal for bench work to sturdy drums in industrial-scale settings. Safety warnings constantly remind users that, like many brominated organics, direct contact or inhalation should be avoided. Labels tie the product to regulatory frameworks including OSHA, REACH, and GHS.

Preparation Method

To make 1,6-dibromohexane, a common way is to treat 1,6-hexanediol or 1,6-dichlorohexane with a halogenating agent like phosphorus tribromide or hydrobromic acid. Some chemists prefer starting from 1-hexene, adding bromine to both ends through a double-bromination step. Each of these methods requires careful control of temperature, reaction time, and stoichiometry to prevent overhalogenation or by-product formation, both of which waste money and slow down downstream work. After reaction, purification steps like distillation or chromatography come in, stripping out color bodies and unreacted starting material. It’s a process that rewards attention and punishes shortcuts.

Chemical Reactions & Modifications

Two reactive bromo groups make 1,6-dibromohexane a versatile tool on the lab bench. Industrial chemists often use it for alkylation, where the molecule serves as a linker or spacer. Reactions with primary amines or thiols lead straight to diamines or dithiols, which are starting points for making specialty polymers, resins, and surfactants. In academic work, I’ve seen teams use it as a skeleton for supramolecular assembly, building up larger architectures that can capture ions or store energy. It’s also handy in making ionic liquids and as an intermediate in the synthesis of more complex organics. In nucleophilic substitution, the bromine atoms get swapped out easily, making way for new functionality. Chemically, it’s flexible but predictable—a quality researchers appreciate.

Synonyms & Product Names

Depending on the manufacturer, you might see bottles labeled as hexamethylene dibromide, hexane-1,6-diyl dibromide, or 1,6-dibromhexan. The chemical structure remains the same, no matter the labeling. Check the CAS number to be sure you’re using the right product, especially if you’re tracking inventory or completing regulatory paperwork.

Safety & Operational Standards

Lab experience teaches respect for chemicals like 1,6-dibromohexane. Skin contact irritates quickly, and prolonged exposure brings bigger problems: headaches and respiratory discomfort, especially in poorly ventilated spaces. Safety data sheets always recommend gloves, goggles, and lab coats, but adding a working fume hood isn’t just best practice—it’s essential. Regulatory agencies stress responsible storage since accidental spills can harm people and the environment. Cleanup routines for brominated liquids involve specialized absorbents and safe disposal in tightly capped waste containers. Companies keep records of training and personal protective equipment use, understanding that mistakes around these chemicals can’t always be fixed by calling the manufacturer.

Application Area

1,6-Dibromohexane doesn’t just sit in warehouses. It moves briskly in sectors where custom organic synthesis rules: polymer research, pharmaceutical development, fine chemicals, and materials science. Manufacturers use it as a building block for surfactant molecules, which turn up everywhere from industrial lubricants to personal care products. In biotech, it helps assemble spacer arms for bioconjugation, vital for diagnostics. Electronics groups have used it to engineer new types of resist materials, often tailoring device features at the nanoscale. Research groups pursue di- and polyfunctional frameworks that bring more performance to batteries and sensors. Use cases shift over time as new challenges and market needs arise, but demand for thoughtfully designed dibromoalkanes keeps on climbing.

Research & Development

Academic and industrial teams can’t seem to exhaust the list of new uses for 1,6-dibromohexane. In the last decade, papers have described its success as a flexible linker in dendrimer synthesis and nanotechnology. Some research moves toward green chemistry—shifting processes away from harsh reagents or high waste. Advanced labs study its potential for smart polymers, expecting performance advantages in self-healing coatings or smart delivery systems. The molecule’s reactivity opens doors in the synthesis of ionic liquids for next-generation batteries and supercapacitors. Every round of research spurs tweaks in reaction conditions, supporting data that pushes chemical knowledge forward.

Toxicity Research

Much of the research on toxicity highlights the predictable results that come with most brominated hydrocarbons: skin, eye, and respiratory irritation in people, and aquatic toxicity in the environment. Chronic exposure can affect the liver and nervous system, raising red flags with repeat use. Lab animals exposed to high levels show clear negative effects, supporting the need for strong containment and disposal routines. Government agencies keep a close eye, updating exposure guidelines to protect workers. Manufacturers and users carry a responsibility to limit releases and handle waste with care, tying health and safety concerns to daily practice.

Future Prospects

The story of 1,6-dibromohexane isn’t finished, even as the world pivots to greener and safer chemistry. Demand keeps shifting towards more sustainable production routes and improved control of emissions and worker safety. Research on bio-based or recyclable brominated intermediates may point toward new pathways that use fewer hazardous materials without dropping performance. In my experience, innovation responds quickly to tighter safety codes and changing customer demands. Teams in academic, industry, and regulatory circles will keep pushing for products that balance performance with environmental impact. As analytical methods sharpen and synthetic chemistry evolves, 1,6-dibromohexane’s role as a reliable building block might adjust, but its importance won’t disappear anytime soon.

Exploring Everyday Chemistry

People rarely think about compounds like 1,6-dibromohexane, but this colorless liquid quietly powers much of the behind-the-scenes work in chemistry labs and factories. This chemical belongs to a group called dihaloalkanes, which means it has bromine atoms at both ends of a six-carbon chain. Its structure makes it useful for building bigger, more complex molecules found in everything from advanced plastics to specialty pharmaceuticals.

Chain Reactions in Polymers

One real-world use of 1,6-dibromohexane shows up in making certain types of polymers—a kind of plastic that can handle high heat or corrosive chemicals. If you want plastics that last for decades or show up in electronics, cables, or high-strength coatings, you need sturdy molecular links. 1,6-dibromohexane works as a "linker" between chains of molecules, letting chemists tie everything together into big, strong networks. Without reliable linkers, manufacturers risk weak or brittle materials—a headache for both consumers and engineers.

Smart Solutions in Pharmaceutical Synthesis

Drug discovery relies on building complex molecules step by step. Chemists use 1,6-dibromohexane to add "handles" to their compounds, allowing them to join different pieces in a controlled way. Imagine trying to snap together LEGO bricks with missing connectors; medicines would be hopelessly difficult—if not impossible—without tools like this. 1,6-dibromohexane allows researchers to test new drug candidates faster and more efficiently, shortening the time before important medications reach patients.

Advanced Chemistry in Schools and Labs

Beyond industry, 1,6-dibromohexane has become a staple in educational labs. College students use it to practice making complex organic compounds, learning how to handle reactive substances and safely conduct experiments. My own time in university labs left me with stained gloves and a strong reminder of the care these substances demand—minor spills can create major hassles, and the sharp, persistent odor sticks with you long after cleanup ends.

Safety, Environment, and the Path Ahead

Using chemicals like 1,6-dibromohexane brings challenges. Handling requires proper training, because accidental contact can irritate skin or eyes and poses risks if inhaled. Manufacturers provide clear instructions for storage, labeling, and disposal, aiming to reduce accidental exposure. This matters both for workers and for the wider environment. Companies rely on fume hoods, ventilators, and well-designed protocols—not just to meet regulations, but to avoid unnecessary dangers. Some groups have started researching greener alternatives, hoping to replace brominated compounds with options that break down safely and work just as well. Green chemistry keeps advancing, but so far, few substitutes match the unique properties of 1,6-dibromohexane.

Insights for Readers and Industry

The next time you plug in your phone or open a childproof medicine bottle, chemical building blocks like 1,6-dibromohexane have probably played a hidden role. As society demands safer, more sustainable solutions, both scientists and industry leaders constantly juggle performance, cost, and safety. The search for better chemicals continues, but for now, compounds like this keep industry, research, and even classrooms running smoothly—and safely—behind the scenes.

Simple Chemistry, Everyday Relevance

Plenty of folks remember chemistry lab, the whiff of alcohol lamps and the challenge of drawing carbon chains. 1,6-Dibromohexane pops up as a simple but important molecule. It fits right into a class of organobromine chemicals, showing up as six carbons in a row, a bromine atom hooked to each end. If we look at this structure, it tells us the molecular formula: C6H12Br2. That’s straightforward, but there’s more to it than the formula on paper.

Why Small Molecules Matter

It’s easy to dismiss these chain molecules as mere lab curiosities, but they show up quietly in industries and research. Years back, I handled something similar in a research lab focused on polymer synthesis. Chain-like dibromo compounds made for excellent starting points. In real-world manufacturing, researchers create new materials for everything from electronics to medical devices using such pieces. These starting chemicals often set the tone for the final product’s safety and performance. Miss a carbon or add one extra bromine and the outcome flips, sometimes with unexpected results. This kind of accuracy makes the correct formula not just a classroom fact, but a piece of information tied to real consequences—economic and environmental.

Making Safety and Sustainability Count

Brominated compounds raise eyebrows for health and environment, too. Always check the Material Safety Data Sheet before opening a bottle of something like 1,6-dibromohexane. It’s not just chemists who should care—waste handlers, warehouse workers, and anyone living near chemical plants face risks if these molecules get loose. Data from the Agency for Toxic Substances and Disease Registry point out that while organobromines are less volatile than related chlorine compounds, they still persist. Industries need tight protocols to keep spills from tainting soil or water supplies. In my own lab experience, spillage meant not only an afternoon lost but a paperwork marathon and a silent lesson in handling hazardous materials.

Smarter Chemistry for a Cleaner World

Industry can’t shift away from functional chemicals at the drop of a hat, but there’s room for improvement. Sourcing greener alternatives cuts risks, and updated handling rules help protect both workers and the environment. Labs can swap out the more persistent brominated compounds for safer analogs or just improve their storage and waste routines. Even small steps—reviews of bottle labeling, regular refresher training—lead to better habits over time.

The Formula Tells a Story

Six carbons, twelve hydrogens, two bromines—on paper, it’s efficient and elegant. In practice, it sits as a reminder of the importance of accuracy in science and the domino effect chemicals have once they leave the bottle. Data in publications and resources like PubChem reinforce why double-checking molecular formulas matters. Small details translate into big impacts in labs, in industry, and in communities downwind and downstream. Respect for the formula fuels respect for safety and for the people working with these molecules every day.

Everyday Chemicals, Real Risks

Stepping into a chemistry lab, glassware lined on metal shelves, you’ll find containers labeled with plenty of long names. 1,6-Dibromohexane is one of those. It doesn’t have a catchy nickname or a warning label that jumps out in neon, but that doesn’t mean it’s safe to brush off as harmless. Used frequently in making chemicals, plastics, and pharmaceutical ingredients, this substance ends up handled more than many people realize.

What Science Says About 1,6-Dibromohexane

Science talks clearly about this one. Inhalation or direct skin contact with 1,6-Dibromohexane can cause irritation. Folks who work in labs or around industrial chemical processes are at the front line. According to the Globally Harmonized System (GHS), it’s classified as a toxic chemical, with specific concerns about harm if inhaled or if it gets on your skin. A report from PubChem highlights that even small-scale exposure over time builds up and leads to headaches, dizziness, or breathing problems.

This chemical finds many uses, especially as an alkylating agent, but that same trait puts people at risk. Alkylating agents change DNA, and with enough exposure, the risk of mutations rises. Results can range from regular allergic responses to bigger threats – animal studies found liver and kidney damage when exposed over weeks. There isn’t enough human data for a definitive answer on cancer, but based on the way similar compounds behave, long-term caution feels wise.

Facing the Hazards at Work

Not everyone in the industry gets the luxury of completely safe conditions. Chemical plants and research facilities rely on personal protective gear: gloves, goggles, and respirators. My time working near research labs showed me that even the best-trained scientists relax their guard after hundreds of routine days, and that’s exactly when accidents happen. A whiff from a leaky flask can sting eyes or throat. Spills on the skin can burn or blister.

Laws help, but enforcement often falls short where budgets run tight. The U.S. Occupational Safety and Health Administration (OSHA) sets guidelines, but gaps in ventilation, broken fume hoods, or simple neglect push risks higher. Busy work environments breed shortcuts. Flimsy gloves, poor labeling, or broken containers make for a recipe no one wants to follow.

Ways to Cut Down the Harm

Commonsense safety takes constant reminding. Labels should use bold warnings, not fine print. Training works best when it uses hands-on drills instead of just lectures. Spill kits belong close by, and so does emergency eyewash. Stocking proper protective equipment isn’t enough—regular checks for rips or old masks keep them reliable. Facilities need to invest in quality ventilation, not just tick a box for compliance.

For people outside the lab or factory, buying chemical products for home experiments or DIY tasks opens a door to risk. Companies could help by making safety sheets clearer and more available to the public. Schools and universities have a duty to show students the right way, not just the easy way.

Looking Ahead

No chemical is evil by default, but ignoring the real harm 1,6-Dibromohexane can cause has led to trips to the ER, skin burns, and long investigations into mysterious headaches. Practical steps, group responsibility, and simple respect for the facts prevent accidents and health scares. Attention in the right places—protection, monitoring, and real transparency—makes even nasty chemicals match safe working lives.

Getting Practical About Chemical Storage

1,6-Dibromohexane doesn’t make headlines like more flammable or notorious chemicals, but it brings with it genuine risks all the same. I’ve worked in labs where almost everybody has a near-miss story involving something as “routine” as a bottle that started to leak or a shelf that grew unexpectedly sticky. The fact is, even with less volatile chemicals like this one, taking shortcuts isn’t worth the fallout. Spilled solvents affect air quality, damage surfaces, and long-term exposure can impact health.

Understanding the Hazards of 1,6-Dibromohexane

This compound is clear and oily, which means it doesn’t announce its presence with aggressive odors or alarming color. That ease of handling can lull even careful people into skipping steps. 1,6-Dibromohexane is harmful if you breathe in vapors, let it touch your skin, or get it in your eyes. Exposure is tied to irritation and there’s debate around long-term effects, so taking its toxicity lightly does no one any favors. Regulatory agencies in North America and Europe flag it as hazardous.

Building Safe Storage Habits

Storing this chemical safely starts with keeping it in containers that won’t react or corrode. High-density polyethylene (HDPE) performs well here, and I’ve seen colleagues regret using glass with questionable caps since halogenated organics sometimes degrade rubber or poorly-made plastic. Containers need to seal tightly, but also allow for easy label checks. It’s tempting to re-bottle a little leftover into whatever is available, but that’s a sure way to invite spill risks or mystery residue.

I always store 1,6-Dibromohexane in a cool, dark spot—never anywhere the temperature swings above room temp. This reduces the formation of unwanted byproducts, which keeps things safer and extends storage life. Chemicals like this want to be away from direct sunlight, which can sneak up fast on a lab bench or poorly covered shelf. Heat can make vapor more likely to form, which is not something you want circulating in the air.

Even more important, I never shelve it near acids, bases, or oxidizers. Reactive neighbors can escalate a minor leak into an emergency. Segregation cabinets cost money, but in every laboratory where I’ve worked, that investment paid for itself with fewer accidents and peace of mind. Even in classroom settings where budgets tighten, wooden cabinets lined with chemical-resistant paint and clear hazard labeling have made a huge difference.

People and Protocols Matter

Superficial policies don’t last. In real-world labs and storerooms, regular walk-throughs and peer checks catch things before they become stories someone shares with regret. I’ve learned that visual inspections—making sure labels are legible, noting date of arrival, and spotting any crusting or discoloration—go further than paperwork ever will. Just knowing what’s in the bottle, and how long it’s been around, can stop surprises later.

Emergency procedures won’t help if folks haven’t rehearsed them. I’ve watched good teams run spill drills and talk out scenarios every few months, so that new faces and seasoned staff can work in sync if something goes wrong. Chemical-resistant gloves, goggles, and fume hoods don’t collect dust when everyone sees the point.

Solutions for a Safer Space

Earning trust with hazardous materials means taking small, smart steps every day. Strong storage cabinets, clear labeling, checking for container integrity, and supporting a lab culture that respects chemical hazards go further than most realize. When new chemicals arrive, taking five minutes to train staff about their risks beats out taking chances every time.

What You Notice Right Away

Every chemist learns fast that no two liquids behave the same on a bench. 1,6-Dibromohexane stays true to that. It’s a colorless liquid at room temperature. It doesn’t take much sniffing to pick up a slight, almost sweet but still sharp odor. Some say it reminds them of other organobromines—less punchy than chloroform, not as sweet as pure ether, but always a sign you should not go breathing too deeply.

Density and Viscosity

Fill a small graduated cylinder and you’ll see this liquid sits on the heavier side. The density lands around 1.48 grams per cubic centimeter at 20°C. That means, if you add it to water, it sinks—not floats. All that bromine packs a lot of weight into a simple organic chain. It pours thicker than hexane, more like vegetable oil than water. Not syrupy, not greasy, but substantial. That difference matters when you’re mixing or separating layers in the lab.

Boiling and Melting Points

It boils at about 255°C, so you won’t see it evaporating at room temperature. If you’ve heated samples under a hood, you know it takes a serious amount of energy and patience to distill this one. If you spill some on your bench and hope it vanishes by itself, you’ll be waiting a long time. In the freezer it does eventually solidify, but only below -1°C, so you don’t run into issues with freezing in everyday storage.

Solubility and Mixing

This compound just doesn’t get on with water. Drop some in a beaker and watch it sink, barely mixing at all. That isn’t surprising given its long hydrocarbon backbone and bulky bromine ends. Try dissolving it in ethanol, chloroform, or ether, and you’ll get much better results. Young researchers sometimes learn the hard way that rinsing glassware with only water leaves a slick residue behind.

Stability and Handling Concerns

With 1,6-Dibromohexane, light and air won’t break it down right away. It does best in dark, cool cabinets, preferably sealed tight. People think twice before letting it sit open on the bench for hours. Human skin absorbs some substances pretty fast, and this one falls in that category. In the lab, gloves are not a suggestion—they’re a must. Chronic skin contact has caused rashes in some workers. I have met chemists who insist on thicker gloves and plenty of ventilation anytime they decant even a small bottle.

Why All This Matters

The heft and chemical nature of 1,6-Dibromohexane make it a go-to reagent for making specialty polymers and custom chemicals. Its resistance to water means it’s useful in reactions where keeping things dry is crucial. Its high boiling point means chemists can heat it alongside other tough materials without losing everything to the air. But good laboratory habits always come into play. Avoid spills, double-check waste protocols, and treat every bottle as worth a second look before you open it.

Potential Solutions for Safer Handling

Better ventilation helps keep fumes at bay. I’ve found that storing it in clearly labeled, amber bottles with tight seals reduces accidents. Setting up a dedicated workspace for halogenated chemicals cuts down on cross-contamination. Training new students in safe skin protection early on prevents a lot of nasty surprises down the line. As more teams move to green chemistry, some are hunting for replacements with lower toxicity, but in specialized synthesis, 1,6-Dibromohexane still carves out a role. With knowledge, the risks stay manageable and science moves forward.