1,4-Dichlorobutane: A Down-to-Earth Look at a Versatile Chemical

Historical Development

The journey of 1,4-dichlorobutane stretches back almost a century, landing right inside the industrial revolution’s explosion in organic synthesis. As chemists began exploring chlorinated alkanes, they figured out that chlorination of alkanes not only shifted how people made plastics, but also opened doors for the manufacture of pharmaceuticals and agrichemicals. This compound started as another curiosity. It eventually earned a role as an essential intermediate, with major chemical companies using different approaches, from direct chlorination of butene to continuous processes involving liquid or gas-phase reactions. Lessons from these earlier methods nudged safety protocols forward, moving from open reactor vessels to closed systems and automation, driven by health concerns and the race for higher yields.

Product Overview

1,4-Dichlorobutane falls under halogenated hydrocarbons. Industries count on it mainly as a chemical intermediate, especially for producing poly(tetramethylene ether) glycol, an ingredient critical to spandex fibers, and in the synthesis of pesticides and specialty polymers. You regularly see it in catalogs under various grades, sometimes tailored to suit lab research, and industrial manufacturing, and even blending for formulations requiring higher purity. Commercial demand doesn’t just reflect a single sector; it spreads across textiles, agrochemicals, and specialty plastics, tying the fortunes of this molecule to wide swaths of the global supply chain.

Physical & Chemical Properties

This clear, colorless liquid carries a faintly sweet odor. Boiling at roughly 161°C, it remains fluid at room temperature, and has a melting point close to -50°C. Its relatively low vapor pressure means it can evaporate if spilled, but not as fast or dangerous as lighter solvents like ether. 1,4-Dichlorobutane dissolves poorly in water, but mixes well with organic solvents such as benzene and chloroform. Chemically, the two chlorine atoms sit at opposite ends of the four-carbon chain, making this molecule flexible in synthesis—able to serve as a nucleophile or to be built into rings or more complex scaffolds. These identical reactive sites allow for efficient transformation into diols and other versatile building blocks for industry.

Technical Specifications & Labeling

Suppliers assign technical specs chiefly based on purity—commonly delivering grades above 98%, with water content, color, and acidity all listed on the certificate of analysis. Labeling requirements match global chemical trade rules. Proper hazard codes—such as GHS signals for acute toxicity, flammability, and warnings about skin and eye contact—appear on every drum and bottle. Companies must list the correct UN number (such as UN 2384) and shipping information for safe transport. I’ve seen the frustration that comes with unclear labeling; mistakes sometimes delay shipments or spark regulatory headaches. Rigorous attention to this information, with barcodes and QR codes for traceability, helps reduce errors and builds much-needed trust among customers.

Preparation Method

You won’t find just one approach to making 1,4-dichlorobutane. One common factory route starts with reacting butadiene with hydrogen chloride, producing 1,4-dichloro-2-butene, which then gets catalytic hydrogenation to remove the middle double bond. Another route treats tetrahydrofuran or 1,4-butanediol with thionyl chloride or phosphorus halides, swapping oxygen atoms for chlorine. These choices depend on local prices, available byproducts, and desired purity. As environmental regulations have tightened, manufacturers have been forced to cut emissions of chlorinated byproducts, pushing for better catalysts and closed-cycle recycling of solvents.

Chemical Reactions & Modifications

This molecule lends itself to a surprising number of chemical changes. Synthetic chemists use it to introduce four-carbon spacers into more complicated molecules. The pair of chlorines at both ends allow for substitutions, letting folks turn the chain into diols with sodium hydroxide or hook it onto aromatic groups via nucleophilic substitution. Reductive dechlorination makes 1,4-butanediol, valued for producing flexible polymers. In some labs, 1,4-dichlorobutane serves as a bridge in making complex, ring-shaped heterocycles or as a precursor for surfactant backbones. These uses have expanded as researchers hunt for greener and faster ways to build useful molecules.

Synonyms & Product Names

Chemists and suppliers have always juggled different names for this compound—1,4-dichlorobutane is the IUPAC label, but trade names like Tetramethylene dichloride or Butane-1,4-diyl dichloride appear in catalogs. Companies sometimes list German, French, or Japanese names too, reflecting its truly international demand. As practical advice, always check CAS numbers (such as 110-56-5) in addition to names. Relying solely on product names can cause confusion, especially when similar-sounding chemicals might pack different hazards or uses.

Safety & Operational Standards

Having worked in labs and walked through chemical plants, it becomes clear pretty fast that safety with chlorinated organics never comes by default. Direct contact with 1,4-dichlorobutane can irritate skin and eyes; workers report headaches or dizziness if exposed to high vapor concentrations. It catches fire at higher temperatures than gasoline, but caution still means using explosion-proof equipment and good ventilation. Organizations like OSHA and the European Chemicals Agency set exposure limits, and most facilities require chemical goggles, gloves, and sometimes air-monitoring. After a close call involving a leaking drum, I started double-checking drum seals and personally ensured proper labeling every time. This attention keeps both people and facilities out of trouble.

Application Area

Textile manufacturers depend on 1,4-dichlorobutane for making spandex, which powers the stretch in athletic and fashion clothing. Polymer folks covet it as a precursor for engineering plastics that must resist chemicals and heat. Agrochemical manufacturers use it to build intermediates that wind up controlling weeds or insects. Small-scale labs reach for it when building research compounds or new catalysts. Electronics industries, always seeking new insulating and dielectric materials, have shown interest in specialized polymers springing from this chemical. This spread across multiple markets ensures that demand keeps ticking, even if one sector slows down.

Research & Development

Research doesn’t stop after decades of use. Green chemistry teams work hard to cut waste and trim the use of hazardous reagents; one trend focuses on catalytic chlorine introduction, avoiding older phosphorus-based chemicals that create hard-to-treat waste. Polymer scientists are exploring chain-length modifications to tweak flexibility and resistance in technical materials. On the toxicology side, researchers revisit worker health studies, aiming to tighten workplace exposure guidelines and monitor long-term exposure risks. Analytical chemists keep refining detection methods, capable now of tracing even tiny amounts leaching into groundwater or air. The persistent drive stems from regulatory changes, but also from the sheer pace of innovation in downstream industries.

Toxicity Research

1,4-Dichlorobutane isn’t among the most acutely toxic chemicals found in an industrial setting, but it still demands respect. Chronic exposure studies in animals point to possible nervous system and liver damage, and high doses depress respiration. Limited evidence suggests this molecule can act as a mild skin or respiratory irritant for humans. Some research links breakdown products to more toxic compounds, like phosgene or hydrochloric acid, under severe heating or fire. Environmental researchers measure how quickly bacteria and sunlight help break down spilled dichlorobutane, trying to understand the risks if it escapes into streams or soil. This ongoing work feeds into stricter spill response procedures, waste disposal protocols, and regulatory reviews around the world.

Future Prospects

Looking out to the future, 1,4-dichlorobutane faces two big forces—ongoing demand for specialty polymers and tightening global chemical safety rules. As countries enact stricter controls on chlorinated compound emissions, chemical engineers must invent new processes with smaller ecological footprints. Biobased pathways, using engineered microbes or renewable feedstocks, are beginning to draw attention and early investment. Niche applications in high-tech fibers, advanced coatings, and specialty battery materials push research across fields. At the same time, some regulatory bodies keep reevaluating allowable exposures in the workplace and the environment. Adaptation, investment in greener production, and proven safety data will likely decide who leads and who drops out in the next chapter for this humble but powerful molecule.

Where You’ll Find It and Why It Matters

This chemical sounds like something you might want to avoid, but its existence plays a part in things you use every day. As someone who’s spent time on plant floors and in labs, I know these chemicals don’t work in the spotlight, yet they hold up entire industries. 1,4-Dichlorobutane gets used as a building block in manufacturing. Take nylon—especially nylon 4,6—its stretchy, smooth fibers owe a debt to this substance. From carpet edges that last through years of foot traffic to hosiery that bounces back after every wear, the path starts with a manufacturer adding 1,4-Dichlorobutane into the process.

It’s also not just fabric. The chemical shows up when making specialty rubbers and polymers. These materials get turned into automotive parts and even seals for high-pressure pipes. Many don’t realize how often daily routines brush up against materials traced back to chemicals like this. From the dashboard of your car to the gaskets keeping water lines tight, each leans on reliable compounds made from basic molecules.

Why Chemists Keep Coming Back to This One

A lot of research looks at efficiency and reliability, and this compound checks both boxes. Its two chlorine atoms help make strong chemical bonds. The reactivity gives producers the flexibility needed to dial in properties for specific goals. If someone’s designing a thinner yet tougher tire, or developing insulation that doesn’t bake in the sun, they can turn to 1,4-Dichlorobutane-based materials.

There’s always this tug-of-war—better performance versus risk. Even in the 2020s, performance wins more often than not. I remember visiting a polymer facility in Texas where the engineers rattled off a dozen variations on plastomers, and almost each relied on some chlorinated intermediate like this one.

The Elephant in the Room: Safety and Environment

With so many uses, safety can’t be ignored. Chlorinated chemicals have a mixed record. Some stick around in soil and water for decades. Others can be downright nasty, causing trouble for people with long-term exposure. The EPA watches over production and storage, and OSHA steps in on the factory floor to outline best practices, from fume hoods to glove types.

People I know in the industry keep their guard up. They double-check the ventilation, run regular training, and rarely let things slide. I’ve sweated through spill drills with them—it isn’t something you forget. But making products safer starts way before spills. It comes down to smarter design, picking less hazardous options where it makes sense, or locking in closed-loop systems to cut down leaks and emissions.

Working Toward a Smarter Approach

Demand for versatile plastics isn’t falling off. Still, the industry can keep pushing for alternatives. Green chemistry isn’t a distant dream—I’ve seen startups scaling up processes with cleaner reagents. Big manufacturers could invest more here, and research grants can help point to new breakthroughs.

Most folks just want the products to work and last, which is fair, but choosing materials that don’t stick around as toxic leftovers helps everyone. Supporting stricter oversight and better cleanup tech could go a long way. For anyone who’s part of the supply chain, from lab bench to loading dock, a bit of vigilance and a mindset open to change never hurts.

Understanding What You're Handling

1,4-Dichlorobutane isn’t just another name in a catalog of chemicals—it's one of those clear, colorless liquids that can surprise you if you let your guard down. From organic synthesis in laboratories to certain industrial processes, people handle it more often than you’d guess. What people might not realize is that skin contact causes burns, the fumes can irritate the nose or throat, and spills soak right through gloves if you choose the wrong kind.

Why Gloves and Goggles Matter

A lot of folks brush off glove choice, but not every pair stands up to this solvent. Forget latex—the chemical punches right through. I once saw a technician trust standard lab gloves, and redness showed up less than five minutes later. You want nitrile or butyl rubber gloves, checked for holes before use. Safety goggles come next. Splashes don’t give a warning, and the liquid stings if even a drop finds your eye. Use tightly fitting goggles or a face shield in busy settings.

Breathing Easy Isn't Automatic

People assume ventilation works silently in the background, but chemical vapors spread quicker than you notice. Even in a fume hood, keep your head tilted away and limit open container time. Never lean directly into the hood’s stream. Larger jobs need respirators with organic vapor cartridges. The National Institute for Occupational Safety and Health (NIOSH) sets exposure limits for good reason—breathing too much vapor causes headaches or worse. I remember a day in summer with weak airflow in the lab; just opening a fresh bottle gave the room a sharp, lingering smell. That’s when you realize how fast fumes build up.

Spills, Storage, and Clean Up

Spills happen, even to careful hands. The key is never reaching for paper towels and hoping for the best. Spread absorbent material designed for chemicals, wearing gloves and goggles, then seal waste in labeled containers. Wash work surfaces with soap and lots of water. Contaminated gloves and rags go straight into hazardous waste—not regular trash. Don’t forget: 1,4-Dichlorobutane burns easily. Keep it away from heat sources, sparks, and open flames, storing it in tightly closed bottles inside a ventilated, flame-proof cabinet.

Planning for the Unexpected

Anyone handling chemicals should have easy access to emergency showers and eyewash stations. You hope you won’t need them, but time counts if something splashes. Get familiar with the location before opening anything. Safety sheets (SDS) stay close by for quick reference. If a spill feels too big for one person, evacuate and let the professionals handle it.

Learning from Each Other

People remember the close calls. Stories passed around the lab—gloves melting, forgotten fume hoods, or near misses with open flames—stick in your head far longer than printed warnings. Regular training refreshes what those stories teach: respect the chemical, respect your own health, and speak up about any shortcut that feels risky. Fewer accidents happen in teams that talk honestly about mistakes and pitch in to spot hazards.

Breaking Down the Chemistry

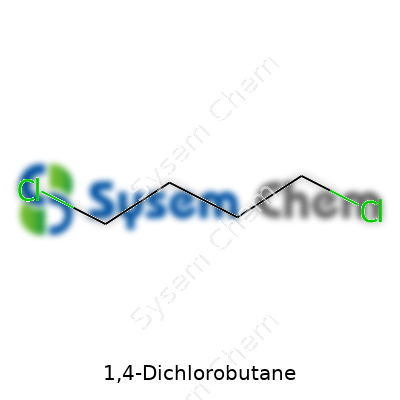

1,4-Dichlorobutane looks simple on paper, but the way its atoms come together opens up conversations about safety, industrial processes, and the endless puzzle of chemical synthesis. The formula is pretty straightforward: C4H8Cl2. Four carbon atoms, eight hydrogens, two chlorines. Now, seeing this formula tells part of the story. What gives this chemical its unique identity is how those atoms line up.

The “1,4” in its name refers to the positions of the chlorine atoms. Chemists number the carbons in the straight chain, and slap a chlorine on carbon number one and another on carbon number four. The structure unfolds in a neat, unbranched line: Cl–CH2–CH2–CH2–CH2–Cl. Both ends carry a chlorine; the center holds two methylene pairs. This layout gives 1,4-dichlorobutane a handful of practical strengths but also means it needs careful handling—chlorinated hydrocarbons never demand carelessness.

Why Structure Matters in Daily Life and Industry

I’ve seen how a detail like the arrangement of atoms doesn’t just matter in the lab. Engineers making rubber, plastics, or specialty chemicals have to trust the right raw material is in the container. Not knowing the difference between 1,4-dichlorobutane and its close relatives can send a production line sideways. This chemical often ends up as a starting point for making other compounds—chlorinated solvents, pharmaceutical ingredients, and, more commonly, the tough, flexible polyamide known as nylon-4,6.

That unbranched chain and terminal chlorines make 1,4-dichlorobutane great for building up longer molecules. It reacts fairly predictably, which helps keep costs low and processes efficient. The recipe counts as old-school organic chemistry: chlorinate a straight-chain butane, separate out the right isomer, and you’re ready to move on. Of course, not every chlorination goes smoothly; I’ve heard stories from folks in industry running into headaches with side reactions or leftover byproducts. That just comes with the territory.

Health and Environmental Considerations

Anyone working with chlorinated chemicals learns quickly to respect them. Many compounds like this can irritate skin, harm the liver, or stick around in the environment longer than we’d like. 1,4-Dichlorobutane is no exception. Direct skin contact or breathing in its vapors calls for prompt action. Thinking about environmental impact, manufacturing facilities turn to scrubbers and strict emissions guidelines to keep these molecules from heading out into local waterways or the air.

Stepping Toward Safer, Cleaner Solutions

Many industries search for options that cut down on hazardous waste and lower toxicity. Green chemistry pushes for ways to swap out substances like 1,4-dichlorobutane for something friendlier to people and the planet. Some companies invest in more efficient catalysts or recycle solvents on-site to limit what escapes into the world. Smart suppliers run regular checks, offer thorough training, and put strong safety data right in the hands of end users. These steps add up—protecting workers, reducing risks, and giving local communities a safer environment.

Final Thoughts on Relevance and Responsibility

1,4-Dichlorobutane’s impact stretches beyond the formula on a label. Its chemical structure shapes the work of chemists, manufacturers, and safety professionals. Paying close attention to every detail ensures better outcomes for health, business, and the environment. This kind of mindful approach pushes the whole field forward, one small molecule at a time.

The Hazards of 1,4-Dichlorobutane

Few chemists or lab managers enjoy dealing with 1,4-Dichlorobutane, and with good reason. This solvent comes with its own story of risks. The liquid gives off a strong odor that hints at its harmful vapors, which can irritate the skin, eyes, and lungs. Even small spills cause headaches for lab cleanup, not just because of fumes, but also due to its flammability. Anyone caught unaware by its irritating vapor learns quickly to treat this chemical with respect.

Why Storage Matters

Poor storage can lead to more than just a bad smell drifting through a lab. 1,4-Dichlorobutane will evaporate easily, and containers left open—or stored in a warm spot—can fill the air with fumes that risk fire and health. I’ve seen poorly stored chemicals lead to false alarms, unnecessary evacuations, and near-misses that could have been avoided with a tighter lid and the right spot on a shelf.

Simple Steps for Storage

Stashing 1,4-Dichlorobutane at the back of a closet doesn’t cut it. There’s a right way, and it starts with choosing a strong, airtight container. Glass works well, but make sure the lid seals tight and won’t crack if dropped. Thick, chemical-resistant plastic jugs hold up if glass makes you nervous, but avoid metal since this solvent can chew through certain alloys over time.

Give the storage spot some thought. Heat and sunlight speed up evaporation and break down most solvents over time. Keep the bottle in a cool, shaded cabinet designed for flammable materials. These cabinets are built to contain a fire for a reason, and they’re worth every penny once something goes wrong down the hall.

Label the container clearly. Sharpie won’t do—use a printed chemical label that stands up to drips and splashes. If someone else grabs a container during a busy morning, there should be no question about what’s inside.

Ventilation and Segregation

I learned early that good air flow matters. Store 1,4-Dichlorobutane where vapors won’t build up. Flammable storage cabinets with venting fitted do a fine job. Never squeeze this chemical in with oxidizers or acids—a forgotten leaky bottle can spell disaster if chemicals mix in a confined space.

Monitoring and Spill Prep

Storage doesn’t stop once the bottle’s tucked away. Check containers for leaks or bulges during regular inspections. Leaks can form as seals wear out, and ignoring them just makes a small problem big fast. Wipe up spills right away using chemical-resistant absorbent pads, with plenty of ventilation. Old rags won’t do—vapors can linger and spread if not contained.

Keep a chemical spill kit nearby, stocked with the right response gear. If the label says goggles, gloves, and lab coats, use them every time. Public health data shows that most lab accidents happen due to skipped precautions, not bad luck.

Building Safe Storage Habits

Over the years, I’ve seen smart storage save labs from major headaches. A little time spent on proper technique keeps people healthy and work on track. Handling 1,4-Dichlorobutane as if it’s always moments from causing trouble—because sometimes, it is—is the surest way to respect both the risks and the team using it.

Understanding an Overlooked Chemical Threat

1,4-Dichlorobutane isn’t something most of us chat about during a coffee break. This industrial solvent shows up in laboratories, factories, and manufacturing spaces. It’s used when making other chemicals, handling polymers, or as a cleaner. You won’t find it on grocery shelves, but people who spend time where chemicals matter might brush up against it, sometimes without even knowing. I spent a year working with chemical databases, and this one rarely raised a red flag in public discussion, despite clear evidence about its risks.

The Health Risks Lurk in Routine Work

Even a quick whiff of 1,4-Dichlorobutane makes you realize you are around something serious. Inhalation can irritate the nose, throat, and lungs. Extended exposure brings headaches and dizziness. Some research points to liver and kidney damage in workers handling it over long stretches. In the late 1990s, studies tracked symptoms in plant employees who bumped up against low concentrations all day. Results showed memory trouble, slow reflexes, and frequent complaints about fatigue. Short-term discomfort turns into bigger problems with barely a warning sign.

Toxicologists pay a lot of attention to how chemicals move through the body. 1,4-Dichlorobutane can pass through skin and the lungs. The liver works overtime trying to break it down, but if the dose keeps coming, the system overloads. Animal testing reinforces concerns over cancer potential. Lab rats exposed to high amounts developed tumors, especially in organs that filter chemicals. No one trusts that data alone can predict human risk, but those results set off alarms for occupational doctors and health regulators.

Why Everyday Precautions Matter

Too often, people hope workplace controls and safety sheets cover the bases. The truth feels different, especially outside strict labs. Proper ventilation, gloves, and full gear don’t always show up on the shop floor or in small facilities. Years ago, during a visit to a plastics plant, I watched as a new hire handled chemical drums without protective sleeves. He believed the splash risk was tiny — less than the hassle of suiting up for “such a quick job.” Over time, decisions like his create conditions for chronic exposure. OSHA and NIOSH set limits, but compliance shifts with staffing and oversight. Too few regular checks leave room for accidents and slow poisoning.

If you think these exposures only hurt seasoned factory workers, think again. Inexperienced staff and temporary laborers face the highest risk. Language barriers, rushed training, and overtime can lead to skipped warnings. Symptoms don’t always follow the same schedule as payroll. A cough or headache here and there can blend into the background, never raising enough concern until something deeper goes wrong. Data from the CDC suggests that chemical incidents usually involve lapses in equipment, training, or both. Solutions come with cultural changes and commitment from leadership.

What Helps Most: Culture Over Compliance

Every time hazardous chemicals come up in safety meetings, real progress depends on honest talk. Management sets the tone when safety isn’t treated as a checkbox. Supervisors who model the right behavior encourage teams to speak up and take precautions that stick. Regular training in plain language and clear labels beat jargon. Equipment upgrades cost less than lost days at work or a trip to the ER. The most effective defense turns out to be a team that watches out for each other, not one waiting for regulators to show up.

1,4-Dichlorobutane won’t make the evening news, but pushing for smarter safety, open discussion, and quick responses to symptoms keeps damage in check. The longer workplaces wait to act, the harder problems become to fix. Health, once lost, doesn’t come back with a memo.