1,4-Dibromobutane: A Closer Look

Historical Development

1,4-Dibromobutane’s story stretches back more than a hundred years, showing up in organic chemistry classrooms and industry catalogues since the early advances in synthetic methods. Back in the 19th century, chemists started to see real possibilities with halogenated alkanes, both as tools in research and as stepping stones for building more complex molecules. This compound made things easier for folks needing a straight-chain dibromoalkane for reactions or product development. As bromination chemistry improved, yields got better, and so did the purity, laying a foundation for its use in polymer, pharmaceutical, and laboratory settings through the twentieth century. I remember seeing its name in older research on synthetic routes for pharmaceuticals and specialty chemicals—proof of its place as a useful starting material.

Product Overview

1,4-Dibromobutane is a liquid with the formula C4H8Br2. It gets used most often as a reagent, a building block for more complicated molecules, and a crosslinker in making certain polymers. Its two terminal bromine atoms give it flexibility in reactions—something that makes it valuable for companies and researchers alike. Supplies come in 25 ml bottles for laboratory training, or in drums if a manufacturer needs it for bulk production. Lots of companies sell it under catalog numbers, which makes ordering and tracking easy. For anyone working in materials chemistry, specialty synthesis, or process development, chances are you’ll run into 1,4-dibromobutane sooner or later.

Physical & Chemical Properties

You won’t mistake 1,4-dibromobutane for anything else on a lab bench. It pours as a colorless to pale yellow liquid, and its density tells you right away it’s heavier than water—almost 1.9 g/cm³. The boiling point floats around 195°C, enough to remind chemists about using reflux condensers. It sees little action outdoors or in open air since vapor pressures stay low at room temperatures. Solubility feels just as expected for a halogenated alkane: it forms a separate layer in water but mixes well in most organic solvents, like ether and chloroform. One of the more impressive things is its chemical stability under storage; the bottle stays reliable tucked away on the shelf, though it’ll react sharply with strong bases or nucleophiles.

Technical Specifications & Labeling

Product labels for 1,4-dibromobutane pull no punches about its hazards. Manufacturers print detailed information covering purity (usually upwards of 98%), batch numbers, and bottling dates. Hazard pictograms warn you about environmental risks, and the SDS calls out the need for gloves and goggles. Specifications sheets show results from gas chromatography and state any impurities, protecing buyers who need high-purity material. I have seen that over the years, companies have responded to regulatory pressure by making labels clearer, SDS easier to access, and online tracking more reliable, which has made compliance audits much smoother for lab managers and purchasing staff.

Preparation Method

Manufacturing 1,4-dibromobutane usually starts with 1,4-butanediol or 1,4-dichlorobutane. Synthetic chemists run bromination reactions using hydrogen bromide or phosphorus tribromide. The process features careful control of temperature and stoichiometry; too little reagent, and the product stays impure; too much, and byproducts crop up. Old textbooks explain how early methods sometimes struggled with yield or byproduct removal, issues slowly ironed out through incremental improvements. Some manufacturers now recycle solvents or apply greener reagents to keep costs down and avoid regulatory headaches over waste disposal.

Chemical Reactions & Modifications

One strength of 1,4-dibromobutane lies in the pair of bromines that sit at opposite ends of the molecule. Synthetic chemists use it as a linker to stitch together rings or attach side chains—particularly valuable for making crown ethers or macrocycles, which play a role in sensors and separation materials. Reacting it with sodium or potassium salts of dithiols or diamines opens doors for macrocyclic chemistry. Companies working with functional polymers often use this compound to link polymer chains, giving finished products improved elasticity or chemical resistance. Over the years, curiosity-driven researchers have chased modifications to swap the bromines for thiols, amines, or even azides—stretching its utility even further.

Synonyms & Product Names

In catalogs or papers, you’ll spot other names: tetramethylene dibromide, 1,4-butylene dibromide, and even 1,4-DBB. Scanning patent documents or older journals, you might find names like butamethylene bromide. These labels come from different suppliers or regions, occasionally sparking confusion if someone’s not watching CAS numbers. Chemists working across borders double-check labels and structure diagrams, since this avoids missteps with stashing or purchasing the wrong bottle.

Safety & Operational Standards

Handling 1,4-dibromobutane calls for respect. Even small splashes irritate skin or eyes, and the heavy, sweet odor signals that inhalation exposure should stay avoided. Chemists with experience know to use fume hoods, nitrile gloves, and eye protection. Storage needs locked flammables cabinets kept away from acids, bases, and open flames. Emergency protocols—like eyewash stations and spill kits—stay sharp in labs that stock this material. Regulatory guidelines keep tightening around inventory limits and disposal, pushing companies to train staff year-round and triple-check labeling. Keeping proper records helps everyone in the supply chain—lab, warehouse, or waste facility—know what to expect and how to handle emergencies.

Application Area

Industry and research both depend on 1,4-dibromobutane. In materials science, it acts as a bridge, producing polymers with improved flexibility or resilience. In medicinal chemistry, the molecule shows up as a stepping-stone for building more complex intermediates—small changes in the structure sometimes shift a compound’s properties in a big way. Chemical suppliers also offer it to labs testing new catalysts or reaction methods. Battery research has started dipping into dibromoalkanes as additives or functionalization agents, a trend I’ve watched grow in recent publications. Some environmental labs use this molecule as a standard or reactant for breaking down contaminants in controlled studies. Agrochemical screens occasionally reach for it, too, since modifications can yield test candidates for protecting crops.

Research & Development

Curiosity drives many of the recent studies involving 1,4-dibromobutane. Right now, labs are looking into its performance in fabricating specialty materials, using it to create microstructures or functionalize nanoparticles. Biochemists and pharmaceutical scientists circle back to this molecule when designing libraries of new bioactive compounds, using it to install alkyl chains or connect functional groups. Environmental chemists have spent time probing ways to degrade or capture dibromoalkanes, as concerns grow about their long-term persistence outside controlled settings. Tech transfer offices nod toward 1,4-dibromobutane’s use in patents covering coatings, adhesives, and advanced textiles. In the last five years, published literature shows a steady trickle of innovation: not blockbuster headlines, but steady, solid progress.

Toxicity Research

Working with 1,4-dibromobutane means respecting its toxicity. Animal studies and accident reports say acute exposure can hurt liver and kidney function, while chronic exposure risks include irritancy and possible mutagenicity. Regulatory bodies set strict workplace limits, but safe handling practices and reliable venting bring exposure closer to zero. Environmental impact, while not the direst among organobromine compounds, takes on added weight since persistence and bioaccumulation can crop up with excessive releases. Companies keep toxicological data under review, following periodic reviews from authorities like the EPA or ECHA. Labs looking for greener synthesis not only reduce risk inside, but help downstream water and waste systems manage less residue.

Future Prospects

The path ahead for 1,4-dibromobutane will trace emerging needs in specialty manufacturing, cleaner synthesis, and responsive regulation. In materials chemistry, new polymers may call for dibromoalkane crosslinkers that improve product specs, and researchers will want to push for scalable, lower-impact production methods. Green chemistry groups could press for bromination alternatives or recovery programs that turn waste into usable product, reducing environmental footprints along the way. Digital tracking and inventory systems in modern labs will probably continue making compliance easier, especially as regulators update standards and reporting. Those keeping up with patent literature and market forecasts spot its continued role as a useful, flexible molecule, valued for its ability to bridge technology needs and current regulatory landscapes—one place where chemistry, commerce, and public safety constantly intersect.

Understanding What 1,4-Dibromobutane Brings to the Table

A chemical like 1,4-dibromobutane doesn’t make headlines the way plastics or pharmaceuticals do, but its reach runs deep. This compound often finds its way into chemical plants, college labs, and even some of the technology behind the everyday products at home. It’s a colorless liquid, but its real work happens in the transformations it sparks.

Where 1,4-Dibromobutane Finds Purpose

When I spent time volunteering at a university research lab, we used 1,4-dibromobutane to build complex molecules, particularly in medicinal chemistry projects. Its structure gives two bromine atoms on opposite ends. That might sound minor, but this feature opens the door for a chain of reactions.

Synthetic chemists generally look to 1,4-dibromobutane when they want to create larger, ring-shaped molecules called macrocycles. These rings play a role in medicines, industrial agents, and advanced materials. Without stable “linkers” like 1,4-dibromobutane, creating these molecules just wouldn’t be so efficient or reliable.

Real-World Impact: Not Just Lab Curiosity

The pharmaceutical industry values it because it helps make molecules that can become antibiotics, antifungals, and other drugs. During my time working with chemical suppliers, I learned just how often companies ask for specialty ingredients that can keep reactions under control. 1,4-dibromobutane likes to add structure – sometimes literally – by building up more complicated molecules through controlled, predictable reactions.

Apart from medicines, it plays a role in polymers and specialty plastics. Some manufacturers use it to create certain types of nylon, which you will find in ropes, fabrics, and even high-performance automotive gear. It also fits into the production of ionic liquids, which are fluids that don’t evaporate easily. These find their way into batteries and other green technologies.

Health, Safety, and Environmental Points

Chemicals like this always come with risks. 1,4-dibromobutane can be harmful if it touches skin or if fumes get inhaled for a long period. Back in my undergraduate lab days, we kept tight protocols for storing, labeling, and cleaning any spills right away. Personal protective equipment wasn’t just a suggestion—it became second nature. Regulations, like those from the Occupational Safety and Health Administration (OSHA), aren’t there for bureaucracy’s sake. They exist because people have learned, sometimes the hard way, about the hazards.

Disposal matters too. Pouring leftover chemicals down the drain or sending contaminated solids to landfill quickly poisons groundwater and soil. Here, I have seen the value of dedicated hazardous waste programs. Such programs protect people and the environment, and they should come alongside research and manufacturing wherever this material is used.

Supporting Safe and Responsible Use

While 1,4-dibromobutane powers a lot of innovation, no one should downplay its toxicity. Training workers, keeping up with maintenance of fume hoods, and investing in quality waste treatment systems—these aren’t luxuries for chemical manufacturers or research labs; they’re part of doing business responsibly. Technologies change, but common sense and strict routines still work best to keep people healthy and the environment intact.

Looking forward, chemists keep searching for alternatives that carry less risk, especially as greener methods and safer molecules come into play. Until then, 1,4-dibromobutane stands as a tool that, when respected and handled with care, can drive forward scientific progress across medicine, industry, and technology.

Why 1,4-Dibromobutane Demands Caution

Handling chemicals at work or in the lab often feels routine, but some substances make you pay attention. 1,4-Dibromobutane counts as one of these. Its job in organic synthesis and industry means it pops up in trusted processes, but its hazards are no joke. The stuff can harm your skin, eyes, and lungs. Inhaling even a small amount burns your throat and chest, and liquid contact leaves your skin raw. I’ve seen gloves dissolve or leak with similar chemicals, so a slip in attention doesn’t pay. Chances of workplace accidents climb when people treat this liquid too casually.

PPE: The Baseline Every Time

There’s a simple truth I learned in the lab. Proper personal protective equipment always comes first, no matter how quick the task. Anyone reaching for a bottle of 1,4-Dibromobutane needs splash goggles, chemical-resistant gloves like nitrile or neoprene, and a lab coat. Standard latex disappears once stronger solvents hit it, so cutting corners isn’t just foolish—it’s dangerous. I often double up with face shields if there’s a risk of splashing. Washing spills off bare skin leaves burns, so full coverage matters.

Ventilation Shows Respect for the Air You Breathe

Don’t trust open windows or standard fans for a job like this. Fume hoods exist because ordinary ventilation doesn't cut it. Aromatic or halogenated compounds like 1,4-Dibromobutane bring invisible fumes that sneak up fast. Chemical exposure piles up. Good hoods keep vapor away from your lungs. Even when working small scale, keeping the sash down and hands behind the shield cuts risks. I always check airflow monitors before starting. If the air isn’t moving, I don’t trust it with my safety.

Storage Woes That Catch the Unprepared

Leaving bottles uncapped or shoved on the wrong shelf causes disasters. 1,4-Dibromobutane isn’t flammable, but storing it in a hot or sunny spot breaks it down, kicking off fumes. Separate organics from strong oxidizers. Lids belong on tight. I keep mine in ventilated, locked cabinets marked for corrosives. Even the best workers make mistakes, so proper labels matter. Quick ID in an emergency saves more than frustration—it saves time if someone ends up exposed.

Cleanup: Immediate, Thorough, Non-Negotiable

Loose drops on your bench or floor aren’t minor. This compound seeps through skin slowly. Spilled material means suiting up with gloves and possibly a respirator, grabbing absorbent pads, and sealing the waste in a drum built for chemical residues. Water alone spreads messes, so skip wet mops. Local regulations describe waste disposal for a reason; I’ve seen regulators fine labs for flushing halogenated waste. Safe cleanup isn’t busywork, it’s part of respecting every person in the building.

Training and Emergency Response: Real Practice, Not Just Paperwork

Reading procedures from a binder lands you nowhere if you haven’t run real drills. Fire extinguishers, emergency showers, and eye wash stations don't help unless people actually know where to find them. I’ve spent countless Friday mornings rehearsing spill response. Every team gets a turn, because hesitation during a leak leads to injuries. MSDS sheets aren’t decorations; they give rescue crews vital information.

Building Smarter Habits

Safe handling of 1,4-Dibromobutane starts before a bottle gets opened. Planning each step, using the right gear, and trusting verified procedures protects everyone. If you think you know enough to skip steps, odds are you forgot something important. The reputation of any lab or company hangs on the health of the people inside. Taking safety seriously with chemicals like this pays back every day with peace of mind and fewer close calls.

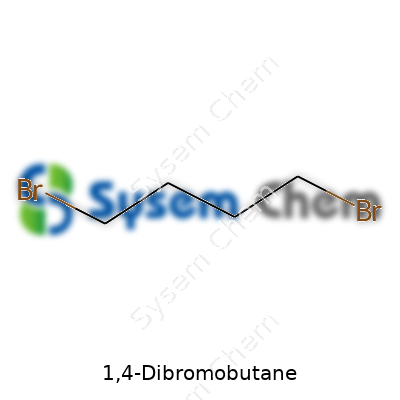

Chemical Formula and Structure

1,4-Dibromobutane carries the formula C4H8Br2. The structure looks like a straight chain of four carbon atoms with bromine atoms attached to each end, almost like bookends. Each carbon atom in the middle gets bonded to two hydrogens, and the two terminal carbons each lose a hydrogen to make space for the bromine atoms. Sketching this on a notepad in a chemistry class can clarify a lot—BrCH2CH2CH2CH2Br lays out the backbone, showing clearly where the bromines land.

Why 1,4-Dibromobutane Matters

This compound seems simple at first glance, but it leads to a surprising range of applications. Back in the university days, I saw firsthand how students used 1,4-dibromobutane in organic synthesis labs to make cyclic compounds. In the world of synthetic chemistry, it’s much more than just another halogenated hydrocarbon. It forms a crucial building block in creating macrocycles—large, ring-shaped molecules that show up in batteries, polymers, and even some medicines.

Looking at industrial manufacturing, chemists use it to introduce the bromine atoms into more complex chemical systems. Its straight carbon chain makes it a go-to starting point for people wanting to connect two ends of another molecule together. Its reactivity comes from bromine atoms. These atoms come off relatively easily under the right conditions, letting other pieces attach and open up the molecule for lots of experimentation.

Real-World Use: From Classrooms to Manufacturing Plants

In research labs, 1,4-dibromobutane has been used to create specialized polymers with unique flexibility and strength. These long chains play an important role in modern material science, including in cable coatings or specialty plastics. Industrial-scale synthesis of polyethers and other robust materials relies on molecules like this one. Chemists appreciate how its straight chain leads to predictable reactions—an advantage when you need reliable results at scale.

It grants vital utility when making bis-compounds, substances with identical reactive groups at each end. These serve as launching pads for larger molecules like crown ethers and cryptands used in ion transport studies. My experience working on student projects confirmed its versatility: even small tweaks in the molecule’s length changed the entire outcome of the experiment.

Concerns and Safer Practices

Chemicals that contain bromine aren’t toys. The toxicological profile for 1,4-dibromobutane means safety goggles and gloves are not negotiable in the lab. Its vapors irritate eyes and the respiratory system. I still remember lectures where professors shared stories about spills and the lingering odor. Anyone working with it needs good ventilation and strict spill-handling routines.

Regulation for brominated solvents and intermediates has tightened over the years. Companies now look for containment strategies and waste treatment technology to keep brominated byproducts out of the environment. Recycling programs within large chemical plants capture used solvents and neutralize waste. Researchers have experimented with less hazardous alternatives in some reactions, but for now, 1,4-dibromobutane holds its place due to its reliability and specific reactivity.

Finding Responsible Solutions

Safer chemical practices and responsible disposal matter not only in big industry, but also in university labs and small businesses. Continued improvements in chemical handling protocols—and support for green chemistry initiatives—offer hope. Teams designing new production lines review old chemistry to strike a balance between efficiency and safety. In my own lab days, peer-checks and open communication made a big difference, cutting down on spills and exposures.

Respecting Its Hazards

It’s easy to ignore the details printed on chemical containers, but you can’t take shortcuts with something like 1,4-Dibromobutane. This compound brings along some real hazards, including flammability and an ability to cause irritation. If you’ve handled it before, the sharp smell sticks out, and skin contact can leave you mildly burning or itching. You don’t want to experience what happens after a spill in an unventilated storeroom.

The Importance of Temperature and Containment

People in labs learn quickly that temperature control prevents surprises. Keep this chemical cool, preferably below room temperature, so vapor doesn’t build up. Too much warmth, and it starts to evaporate. Leaving it near a heat source makes no sense—improper storage often leads to incidents, and a little attention saves piles of paperwork and health risks later.

Tightly sealed glass or metal containers do the trick. Ordinary plastic sometimes gets attacked by strong solvents, so nobody wants that mess. If you’ve ever picked up a leaking container that looked fine the day before, you’re not likely to forget that lesson. Any sign of moisture or damage means container replacement, without delay.

Steering Clear of Incompatibles

Certain chemicals never belong together on a shelf, no matter how convenient it looks. 1,4-Dibromobutane needs to avoid strong oxidizers. Combine these by accident, and you don’t just end up with ruined stock—sometimes it leads to fires or hazardous fumes. Even strong acids or bases could trigger decomposition or unexpected reactions, so separate storage lockers become worth the extra walking.

Good Ventilation and Secure Locations

A storeroom with stale air might save on utility bills, but lack of airflow leads to health risks. The safety data backs this up: vapor from 1,4-Dibromobutane builds up quickly. You can taste it in the air before spotting a leak. Mechanical ventilation pulls away these vapors before folks working nearby take in more than they realize. Anyone who’s tried finding the source of an odd chemical odor in old cupboards knows how persistent these fumes can get—good air movement solves the problem long before alarms sound.

Locks aren’t just for liability protection. Only trained staff should reach these chemicals, since too many accidents stem from curious hands. Locked doors, regular inventory checks, and logs keep track of who used what. I’ve seen chemical stocks go missing, only to realize someone borrowed a sample without following procedure. Tracking access makes sense.

Tackling Spills and Waste

Nobody wants to find out about proper cleanup in a crisis. Always have absorbent pads, neutralizing agents, and personal protection ready nearby. If spills happen, quick action limits the spread—chemicals have a way of finding cracks in the floor or drains faster than you’d think. Treat waste as hazardous, following disposal regulations closely. Years of fieldwork proved that shortcuts in one moment lead to expensive remediation later.

Building a Safety Culture

Storing 1,4-Dibromobutane doesn’t seem dramatic, but proper handling reflects a bigger attitude toward workplace safety. Labels, dated inspections on containers, and frank discussions about risk lift everyone’s awareness. Supervisors setting the right example go further than warning posters ever could. Sharing experiences and learning from mistakes from the past builds habits you can actually trust.

Looking Forward

Labs and storerooms keep changing, but safe chemical storage keeps showing its value. Better storage saves lives, health, and resources. Setting good habits now means fewer surprises in the future—for you, coworkers, and anyone else sharing the space.

A Closer Look at 1,4-Dibromobutane

Anyone who has spent a little time in a chemistry lab or browsed a chemical supplier's catalog would have come across 1,4-dibromobutane. It’s a compound mostly known in academic and industrial circles for its role in synthesizing specialty polymers and various organic compounds. Despite being a simple-looking molecule—just a four-carbon chain with a bromine atom on each end—it brings a mix of qualities that can surprise the uninitiated.

Physical Appearance and Basic Data

1,4-Dibromobutane shows up as a colorless to pale yellow liquid, not something you’d mistake for a kitchen cleaner or a drink. With a molecular weight of 215.94 g/mol, it packs some heft for its size. It doesn’t float on water; with a density hovering around 1.99 g/cm³ at room temperature, it sinks readily. I’ve knocked over a bottle before—the stuff settles in water, refusing to mix, which reminded me senses matter in handling chemicals.

Volatility and Boiling Point

One point that’s hard to forget is how this compound behaves with heat. Its boiling point sits at about 195 to 197 °C. You need a serious hot plate to get it bubbling—the steam rising off it looks a little ominous, too. With a melting point close to -35 °C, it stays liquid under most lab and industrial conditions. This makes storage routines a tad easier, especially if you’ve ever dealt with chemicals that freeze up or solidify in cool storage.

Solubility and Smell

1,4-Dibromobutane does not get along with water; it stands apart with its low water solubility. Yet, it mixes easily with many traditional organic solvents like ether, chloroform, or acetone. That points to its non-polar nature, something I remember clearly from college lab exercises on extractions. One whiff of this liquid provides a mildly sweet but unmistakably chemical odor—always a cue to check your ventilation.

Stability and Handling Challenges

The chemical shows reasonable shelf stability if kept cool and sealed, away from sunlight. At the same time, the bromine atoms bring reactive potential; left with strong nucleophiles, the molecule is eager to swap out its bromines, which explains its popularity in making macrocycles and other complex structures in research labs.

Potential Concerns and Precautions

Contact with skin leads to irritation unless counteracted quickly. The vapor will irritate the nose and throat. Safety data sheets recommend gloves, goggles, and a fume hood—a reminder that even non-flammable liquids deserve respect. I’ve seen blue nitrile gloves swell after a careless drop, which isn’t something you forget. Inhaling or ingesting the liquid brings even greater risks, calling for thoughtful storage and waste practices.

Looking to the Future: Safer Alternatives and Green Chemistry

With all that’s known about its reactivity and toxicity, chemists keep searching for safer alternatives or cleaner handling methods. Switching to less toxic dihalide compounds and keeping strict inventory control help minimize waste and accidental exposure. Investing in better lab training and engineering controls could prevent accidents and streamline processes. More researchers now look at renewing catalyst systems or alternative, renewable feedstocks to cut down dependence on hazardous alkyl halides like 1,4-dibromobutane. The big picture here focuses on safety, health, and environmental responsibility, points that matter as much in a high school chem lab as they do inside massive industrial plants.