1,4-Dibromobenzene: Substance Story and Substance Impact

Historical Development

Long before designer molecules took center stage in chemistry, organic compounds like 1,4-dibromobenzene became lab workhorses for practical synthesis and industrial processes. Early aromatic dibromides such as this one offered chemists a window into electrophilic substitution mechanisms. Its symmetric structure made separation and characterization easier – a true comfort in the days before high-res chromatography. Over the decades, refinements in halogenation technology let factories make this compound on larger scales, carving a reliable niche in both academic and industrial settings. Bench chemists of the 20th century recognized that once you could control dibromination on benzene rings, a lot of downstream work with dyes, pharmaceuticals, and functional materials opened up.

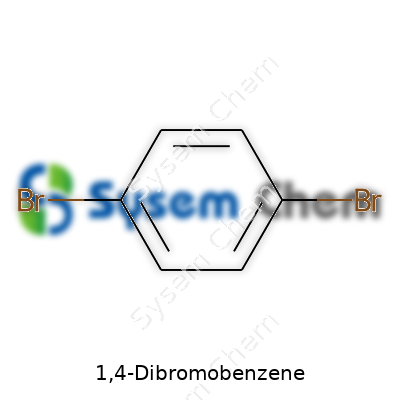

Product Overview

1,4-Dibromobenzene, usually found as a white to slightly off-white crystalline solid, delivers more than just lab utility. Chemists often lean on its straightforward substitution pattern to anchor multi-step syntheses, making it less about esoteric specialty chemicals and more about practical choice. It’s structurally simple: a benzene backbone wears two bromine atoms exactly across from each other. You see it pop up in synthesis schemes, polymer design, and even in niche pesticide formulations. Its market footprint crosses different industries — from chemistry teaching labs to manufacturing setups, it’s a familiar face.

Physical & Chemical Properties

With a molecular formula of C6H4Br2, 1,4-dibromobenzene is dense, packing in the bromine twins on an aromatic ring. The compound melts around 87°C — a sweet spot for recrystallization, but far from volatile. Its boiling point stretches up toward 220°C, so in practice, heat doesn’t quickly drive off this solid. It has a subtle, not unpleasant, odor — something like halogenated mothballs. It resists many common reagents, yet strong nucleophiles and reducing agents can pry off the bromine atoms, so storage and compatibility matter. Not especially soluble in water, but organic solvents such as ethanol, ether, and chloroform handle it quite well, making dissolving and recrystallizing fairly routine lab tasks.

Technical Specifications & Labeling

Commercially available grades of 1,4-dibromobenzene show clear labeling about purity (typically upwards of 98%), moisture content, and trace impurity thresholds — heavy metals, residual benzene, chlorinated byproducts. Safety pictograms for toxicity and environmental impact stay visible on bottles. Genuine labeling documents usually spell out the batch number, date of manufacture, and handling precautions. A well-run operation never skips the MSDS (material safety data sheet), providing straightforward advice on reactivity and exposure risks. This transparency lets researchers, students, and workers assess what they’re dealing with at a glance and check compliance with local regulatory bodies.

Preparation Method

Student chemists learning reaction mechanisms often start with the controlled halogenation of aromatic compounds. Dumping elemental bromine onto benzene with an iron catalyst gives mostly monosubstitution, but adding a second equivalent and careful temperature control pushes the reaction to the para-dibromo derivative. Industrial operations use modern catalysts and reactors that shield workers from concentrated bromine while dialing in selectivity for the para-position. Post-reaction, a wheeling centrifuge or filtration step isolates the crude solid, and recrystallization polishes off the product. Purification with hexane or ligroin provides clean samples without excessive solvent waste.

Chemical Reactions & Modifications

1,4-Dibromobenzene stands out as both a reagent and a building block. Organometallic chemists appreciate how the aromatic bromides couple easily with metals like magnesium or lithium to build Grignard or lithium reagents. These, in turn, offer a reliable path to new carbon-carbon bonds, pretty much the holy grail for advanced organic synthesis. The bromo groups swap for nearly anything: amines, boronic acids, organostannanes. Grafting functional groups at the para-positions lets material scientists and pharma researchers tailor molecules for specific properties, from polymer chain ends to receptor-binding ligands. The molecule’s symmetry simplifies final purification — if there’s unreacted starting material, the TLC spots don’t hide.

Synonyms & Product Names

Depending on catalogs and countries, the compound appears under different names: para-dibromobenzene, p-dibromobenzene, 1,4-dibromobenzol, or its more formal IUPAC moniker. Some suppliers highlight its use in specialty chemical blends, labeling inventory for custom applications. The array of commercial nomenclature reflects regional trends in teaching and manufacturing — in legacy documentation, “p-DBB” or “para-dibromo” shows up almost as shorthand.

Safety & Operational Standards

You won’t hear folks shrug off safety with dibrominated aromatics. Even if 1,4-dibromobenzene doesn’t burn skin outright, it still poses real risks. Direct, repeated contact causes irritation, and the dust off a new bottle can catch you off guard in a poorly ventilated workspace. Inhalation brings headaches or dizziness, and long-term exposure raises questions about impacts on liver and kidney function. Proper gloves, goggles, and chemical fume hoods make up the necessary kit for handling. Spills require careful cleanup — the environmental persistence of halogenated aromatics remains a concern for wastewater streams. Disposal must comply with local hazardous waste protocols, ensuring the stuff doesn’t wind up in the nearest landfill.

Application Area

Industry leans on 1,4-dibromobenzene not for glamour, but for reliability. Take pesticide and fumigant blends — brominated aromatics like this can act as active ingredients or intermediates. Over in plastics factories, it plays a part as a key monomer or cross-linking agent for specialty polymers with heat-resistant traits. Students preparing for organic exams use it as a trustworthy test for substitution reactions. On the research side, chemists value its rigid benzene scaffold as a launchpad for new ligands, dyes, and pharmacophores. Electrical engineers have even used derivatives of 1,4-dibromobenzene to develop new materials for organic semiconductors and OLEDs.

Research & Development

The quest for new reactions keeps drawing labs back to 1,4-dibromobenzene. Researchers focus heavily on sustainable and green chemistry — swapping out heavy metals for environment-friendly catalysts and seeking solvent choices with less toxicity and waste. Techniques like microwave-assisted synthesis and flow chemistry help shrink reaction times and boost selectivity, opening doors to higher yields with reduced environmental footprint. Interdisciplinary teams also explore its potential as a starting material for advanced nanostructures, linking organic synthesis with materials science in ways unheard of decades ago. This compound rarely steals headlines, but it creates space for real innovation in chemical manufacturing methods.

Toxicity Research

No one should gloss over the toxicology. Studies show that direct ingestion or chronic inhalation spells trouble for lab animals — think liver, kidney, and neurological effects. Early toxicity studies, sometimes crude by today’s standards, led to sharpening workplace exposure limits and personal protection recommendations. Recent research looks at breakdown products: as the molecule degrades, bromophenols and related species arise, some with higher bioaccumulation and aquatic persistence than the parent. Regulators scrutinize environmental monitoring data, and ongoing studies weigh both acute and chronic impact. We all benefit from better test models, since much baseline data dates back half a century.

Future Prospects

As chemists shift toward greener synthesis and manufacturers retool for stricter regulatory climates, 1,4-dibromobenzene faces both challenges and opportunities. The demand for halogenated aromatics remains steady for certain specialty applications, but the drive for safer, less persistent chemicals tightens scrutiny. Better recycling protocols and reclamation techniques can capture waste from factory streams, reducing long-term ecological lock-in. In high-performance materials development, para-dibromobenzene continues to offer a gateway to functionalized monomers for advanced electronics and custom polymers. Research efforts aimed at finding biodegradable or rapidly degradable substitutes — or tweaking the structure for safer use downstream — promise a future where foundational compounds like this still matter, just with more responsibility riding on their production and disposal.

Everyday Chemistry at Work

Among the piles of aromatic compounds that fill chemical catalogs, 1,4-dibromobenzene probably won’t win a popularity contest among the general public. Still, for anyone who spends time working with molecules, its name doesn’t sound so obscure. It’s a solid, white substance often found in laboratories, and it comes with a set of interesting uses that touch different industries. Over the years, I’ve seen this compound land on inventories both as a handy building block and as something to be handled with respect. Let’s walk through where it really plays a role.

Key Humble Uses in Synthesis

Chemists look at 1,4-dibromobenzene as a reliable stepping stone for making new molecules. The two bromine atoms sitting opposite each other on the benzene ring offer a unique reactivity—good for targeted reactions. It’s not a stretch to say this molecule shows up when someone wants to create more elaborate, valuable compounds. In the lab, I relied on it for building larger aromatic systems, often in the world of ligands and specialty polymers. Its value comes from the fact that each bromine atom can easily participate in cross-coupling reactions, especially Suzuki or Heck reactions, which are crucial for research and industrial chemistry.

The pharmaceutical industry takes advantage of these same characteristics. By swapping out bromines and attaching functional groups, drug researchers quickly generate diverse candidates for testing. Even if a final medicine rarely includes 1,4-dibromobenzene’s skeleton, it speeds up the process of inventing new compounds. In short, it’s a launching pad. Some well-known agrochemical intermediates also rely on it, thanks to the reactivity of the brominated sites.

Materials Science and Beyond

It doesn't stop with laboratory experiments. There’s demand for specialty polymers that show real resistance to heat or fire, and 1,4-dibromobenzene often joins the game as a monomer in those chains. Electronics manufacturing depends on materials with exacting specifications, and brominated aromatics can help turn up the performance of circuit boards or housing materials. This compound also shows up as a flame retardant precursor; some modified plastics include aromatic bromides to help slow combustion.

In another direction, I’ve encountered it as a labeled chemical standard for analytical work. Its clear structure and stability make it useful for calibrating equipment. Some trace analysis methods in environmental labs benefit from having straightforward, well-understood compounds like this around.

Considerations and Safer Practices

Handling 1,4-dibromobenzene brings up a serious point about safety. Brominated organics, especially in large amounts, call for thoughtful storage and disposal. Over time, questions about environmental impact have grown, especially with other persistent brominated chemicals drawing scrutiny for bioaccumulation. For that reason, careful process controls become important in factories and research settings, both to cut waste and limit exposure. Substitutes with less environmental baggage remain a goal, but so far nothing matches the same mix of reactivity and stability in many applications.

Whenever someone suggests new chemical solutions, it’s worth digging into alternatives that offer similar performance without lingering environmental concerns. Some labs now direct efforts at “greener” cross-coupling methods or tweak polymer recipes to tone down reliance on legacy compounds. That said, the versatility of 1,4-dibromobenzene remains essential for plenty of research and industry tasks—at least until a better tool turns up.

Peeling Back the Layers

Chemistry shapes the world around us, even if we don’t always notice. One compound, 1,4-Dibromobenzene, pops up in conversations about industrial chemistry and organic synthesis. Its chemical structure might sound intimidating, but the basics go a long way in understanding why it matters and how it shows up in daily life and industry.

Breaking Down the Formula and Structure

The formula for 1,4-Dibromobenzene comes out as C6H4Br2. The name points out the twin bromine atoms sitting opposite each other on a benzene ring—think of the ring like a hexagonal racetrack, with two cars (the bromines) parked on spots directly across from each other. This positioning is also called the “para” configuration. A benzene ring alone brings aromatic stability, but swapping two hydrogens for bromines at the 1 and 4 spots gives the compound new reactivity.

Staring at its chemical structure, imagine a six-carbon ring with alternating double bonds (the benzene ring) where hydrogen atoms usually surround every corner. Here, the hydrogens on the 1 and 4 spots get replaced with bromine atoms, while the rest stay as hydrogen. This setup not only shapes its reactivity but also helps give 1,4-Dibromobenzene its physical properties, like a distinct, sweet odor and a tendency to crystallize easily.

Why It Matters Beyond the Lab

Some folks only meet compounds like this in a textbook, but the impact stretches further. The way bromines lock into the benzene ring changes everything about how the molecule behaves. In manufacturing, this means it stands as a useful building block for dyes, pharmaceuticals, and flame retardants. The two bromines, fixed so predictably on the ring, allow chemists to add or swap new chemical groups with precision. Practically, it saves time, cuts waste, and raises the reliability of end products.

As a person with a background in environmental chemistry, I’ve seen how these compounds turn up during checks for industrial pollution. Brominated aromatics resist breaking down, sticking around in water or soil longer than simpler hydrocarbons. So, while they’re valuable raw materials, they need careful handling, both in production and disposal.

Staying Safe With Smart Chemistry

People in manufacturing take cues from strict safety standards. Gloves, goggles, and solid ventilation remain non-negotiable. Over the years, I’ve learned not to underestimate the potential of these molecules to cause skin and eye irritation, or to linger in the environment if spills happen.

Solutions don’t just stop at personal protective gear. Closed systems, better leak-proof equipment, and regular training go a long way in cutting unintended exposures. Many production sites now use “green chemistry” goals, swapping out brominated compounds where safer options exist or recycling them before they reach the environment.

Thinking Toward the Future

Chemistry never stops evolving, and neither do the ways compounds like 1,4-Dibromobenzene get used. Research keeps hunting for alternatives that break down more easily after use. Transparency about the risks and benefits, both for workers and the public, ensures progress continues responsibly. The structure—two bromines on a benzene ring—offers a lot to work with, but also challenges to face head on.

The Real Impact of 1,4-Dibromobenzene Exposure

Ask anyone who does regular work in a lab, and they’ll probably tell stories about handling odd-smelling, crystalline chemicals with complicated names. 1,4-Dibromobenzene isn’t exactly a household word, but it shows up in places most folks never notice. Used in organic synthesis, in some pesticides, and as part of a handful of specialty products, its presence stretches quietly through more of the industrial world than most people realize.

A lot of safety data exists on 1,4-dibromobenzene. Agencies like the EPA flag it as potentially hazardous. Based on my own time working around chemical storage—the kind of rooms lined with bottles of compounds that can make your eyes water—this particular substance commands respect.

Toxicity: What the Data Shows

Short-term effects tend to show up fast. Inhaling dust or vapors causes irritation in the nose, throat, and lungs. Itchy eyes or sore throats prompt quick reactions, but repeated exposures tell a deeper story. Over longer periods, workers who encounter it regularly start talking about headaches, dizziness, and sometimes skin rashes. Some studies have shown it can hit the liver and kidneys after heavy or prolonged exposure, especially if it gets absorbed or inhaled repeatedly.

Animal testing historically played a big part in figuring out toxicity. In those studies, high levels of 1,4-dibromobenzene caused damage to the liver, kidneys, and blood. It’s not wise to skip over those data points. While it doesn’t have the infamous reputation of something like benzene itself, there’s enough red tape around it to keep it out of general consumer products.

Environmental Worries

Runoff and spills present real concerns. In areas surrounding chemical manufacturing, folks who fish or garden sometimes see warnings about traces of halogenated benzenes—including this one—in soil or water. It lingers, doesn’t break down easily, and can move through groundwater. Wildlife, especially aquatic life, suffer when concentrations build up. The risk isn’t theoretical; it’s documented through monitoring results in a handful of industrial towns.

Reducing Hazards in Everyday Use

In my labs, we relied on gloves, lab coats, and strong fume hoods every time we cracked open a jar with this chemical. Skin contact invites problems, so direct handling gets avoided. Warehouses that store it keep containment equipment handy. If a spill happens, a cleanup plan swings into action before there’s a chance for vapors to spread or residue to leach into drains.

On the municipal side, wastewater systems use chemical monitoring for substances like 1,4-dibromobenzene. These efforts keep levels in check and trigger response if a spike appears. Policies require companies to report and reduce releases, and fines enforce good behavior. Education makes a big difference too. Training sessions break down the ways to prevent exposure, spot symptoms, and decide what counts as a real emergency.

Moving Toward Safer Alternatives

A lot of industries keep searching for drop-in replacements to make processes safer. Green chemistry focuses on molecules that break down in the environment or present less risk to people. Progress moves slowly, especially where performance and cost win out, but a steady shift has started. Product safety data sheets become clearer every year, and workers learn to push for answers instead of settling for the easy route.

Looking back, many places handled 1,4-dibromobenzene with more confidence than caution—until researchers started voicing concerns. Those lessons shape how similar chemicals get treated today. Nothing replaces direct communication between scientists, manufacturers, regulators, and workers. Chemistry might seem like backroom work, but the choices shape everything from workplace health to what ends up in local rivers.

Understanding What’s In Front of You

A lot of people will walk past the name 1,4-Dibromobenzene in a lab or warehouse and keep on moving, not thinking twice. Yet this chemical holds risks that can catch even a veteran technician off guard. It gives off a sharp, mothball-like smell, so your nose usually catches it before your eyes do. Anyone who’s spent time around chemical stockrooms knows funky odors are often a red flag.

Chemical Properties with Real-World Impact

1,4-Dibromobenzene turns to vapor easily at room temperature. This vapor isn’t something you want inside your lungs. Exposure can lead to headaches, dizziness, or long-term complications for folks working with it day after day. Gloves rated for chemical resistance, splash goggles, and long sleeves aren’t for show—they keep vapor and dust off your skin and out of your body.

Spills do happen. I’ve watched new lab assistants see a small pile of this white crystal hit the counter and reach for a paper towel as if it’s just salt. In those moments, proper training and discipline count. Grab the proper chemical spill kit, and make sure ventilation is running at full tilt. Doing it right each time builds muscle memory, and it saves time, money, and potentially someone’s health down the line.

Common Sense Storage: Out of Sight, Never Out of Mind

I once worked at a university where the storage policy meant chemicals like this stayed locked away in a cool, dry area. High shelves and strong sun weren’t part of the plan. Plastic or glass containers with airtight lids kept moisture out and vapors in. Labels stayed clear and didn’t fade, so nobody made dangerous mix-ups. Some chemicals can break down or even become dangerous with the wrong neighbor on a shelf. 1,4-Dibromobenzene can react if stored next to strong oxidizers, so keeping an updated inventory and reading those labels every week kept everybody honest and safe.

Fact: Fumes Find a Way

Ventilation matters more than most folks think. Locker rooms for chemicals aren’t where you cut corners. Fans, fume hoods, and exhaust vents keep air moving and stop the slow buildup of fumes that can linger for hours or days. If you forget, a single whiff in a locked supply closet reminds you why professional standards create real protection.

Disposing Without Regret

Disposal turns into trouble fast if people ignore the rules. I remember a case where someone tossed unused 1,4-Dibromobenzene crystals in the regular trash, thinking “it’s just a little bit.” The clean-up crew wore full hazmat suits for a reason. Special hazardous waste containers, recorded pickups, and clear logs turn what could be a disaster into just another part of the work week. It only takes one shortcut for a safety record to fall apart.

Culture and Consistency Build Safety

Even with the best gear, training, and facilities, company culture seals the deal. Encourage people to question odd smells, sticky residue on a glove, or an unmarked jar. Reward those who double-check storage cabinets and keep written logs tidy. Every safe chemical technician has a story about an accident narrowly avoided thanks to vigilance. That vigilance, rooted in respect for chemicals like 1,4-Dibromobenzene, keeps workplaces healthy and running smoothly.

Knowing the Numbers: Melting and Boiling Points

1,4-Dibromobenzene—a mouthful of a name. In the world of chemistry, this chemical stands out because of some very concrete facts: it melts at about 86°C (186.8°F) and boils at around 220°C (428°F). Why care about these temperatures? Anyone working in a lab, manufacturing, or handling chemicals should pay attention. These numbers don’t just sit in textbooks. They guide how to store, transport, and work with the substance every day.

Old Lessons from Lab Benches

There’s something about watching a compound change from a solid to a liquid, or from a liquid to a gas, that grabs a young scientist’s mind. I remember running those first melting point tests, eager to compare the outcome with what the textbook promised. When a sample of 1,4-dibromobenzene morphs into a liquid a little above eighty-six degrees, you know you’ve got the right chemical—or you know something’s amiss if the temperature is off. Boiling it, on the other hand, takes more heat. At 220°C, vapor moves thick and steady, and any safety shortcut spells trouble in the lab.

Safety Grows from Simple Numbers

Melting and boiling points tell a safety story. If a chemical melts at a low temperature, simple room heat or a warm storage shed in summer could turn it soft or liquid. Not great for spills. 1,4-Dibromobenzene stands firm well above room temperature, reducing those accidental messes during storage. In terms of boiling, reaching 220°C asks for a committed heat source. This means accidental vapor in the air—usually responsible for inhalation risks—won’t happen unless someone seriously overheats it.

But the trouble starts if your temperature controls slip, or your equipment overheats. Proper gear, ventilation, and constant temperature checks keep handlers healthy. I’ve seen even seasoned techs overlook the heat source until a stubborn beaker clouds up the hood. Awareness of these simple numbers stops costly or risky mistakes before they start.

Industry Use and the Importance of Accuracy

1,4-Dibromobenzene sometimes plays a part in making dyes or as a reference point for calibrating equipment. Factories need to know precisely when the substance changes state. A process designed to run at temperatures near 86°C, for instance, must tread carefully or risk melting where it shouldn’t. Boiling, even more so—we’re talking specialty glassware and high-heat sources, not to mention protective equipment for workers and proper venting. If a shipment gets stored next to a heater, or a reaction isn’t monitored, the risk skyrockets.

Anyone relying on these numbers should double-check their sources. Mistakes get expensive or hazardous fast. Many credible databases, like the National Institute of Standards and Technology (NIST) Chemistry WebBook, list these values. There’s no shame in confirming what you think you know with the latest data. In research or industry, relying on unverified secondary sources, word of mouth, or a memory from years ago opens the door to accidents and lost materials.

Bringing Chemistry into the Real World

Facts like melting and boiling points might feel dry on the surface. Yet for anyone mixing, storing, or studying chemicals, these numbers are more than trivia—they’re the backbone of good practices and safe work. Keeping tabs on that melting point at 86°C and the boiling threshold at 220°C means smoother operations, fewer surprises, and a safer workspace. Science stands on the details. Paying attention to the state changes of something as specific as 1,4-dibromobenzene fits the same pattern.