1,3-Dibromobenzene: An In-Depth Look at a Versatile Compound

Historical Development

Chemists in the late 19th and early 20th centuries were fascinated by brominated aromatics. 1,3-Dibromobenzene came out of early work as researchers mapped out the possibilities of selective halogenation. Back then, making substituted benzenes involved a fair bit of trial and error because purification tools were basic and yields could swing wildly. Synthetic organic chemistry moved fast after the World Wars, and so did the methods for producing and purifying 1,3-dibromobenzene. Today, picking up this compound isn’t a hassle—the supply chain reaches academic labs, fine-chem producers, and multinational firms.

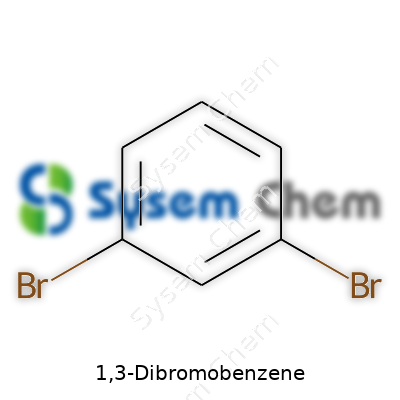

Product Overview

1,3-Dibromobenzene stands as a solid example of what happens when you start swapping out hydrogens for halogens on a benzene ring. The two bromine atoms at the meta positions shape the way this molecule interacts, reacts, and performs. In the lab, it’s a frequent visitor—used in creating more complex molecules, testing new synthetic routes, and acting as a scaffold for other functional groups. Physically, it brings a recognizable white, needle-like solid form and a melting point on the lower end, which keeps things straightforward when measuring, storing, or heating it. Commercially, suppliers typically offer it in gram-to-kilo batches, sealed up tight with labeling that meets both safety rules and research needs.

Physical & Chemical Properties

As a chemical, 1,3-dibromobenzene has a melting point at roughly 86°C and boils around 220°C. It carries its weight with a molecular formula of C6H4Br2 and a molar mass just over 235 g/mol. Insoluble in water, it prefers hanging out in organic solvents like ether, benzene, and chloroform. Its density feels quite a bit heavier than water, so it settles into two phases if mixed in the wrong medium. The strong, sweetish odor signals its aromatic character, but the real interest comes from the polarizability of those bromine atoms. Hook it up with a nucleophile or run it through a coupling reaction, and you’ll see its unique reactivity in action.

Technical Specifications & Labeling

In the world of specialty chemicals, suppliers list assay grades, trace impurities, moisture content, and recommended storage conditions right on the label or accompanying safety data sheets (SDS). Shipping laws for hazardous materials usually apply, given both its toxicity and fire potential. Production standards call for high purity—often ≥99%—with regular tests such as NMR, GC-MS, or HPLC providing supporting data. The packaging itself ranges from small amber glass bottles for lab use to sturdy drums for industry, fitted with tamper-evident seals to prevent moisture and contamination. Regulatory info lists harmonized tariff codes, UN numbers, and GHS (Globally Harmonized System) pictograms, all in line with chemical handling law.

Preparation Method

Synthetic routes usually begin with benzene or 1,3-dinitrobenzene, running these starting materials through direct bromination under iron(III) bromide catalysis. Controlling the temperature and concentration avoids nasty side reactions and polychlorination. Some labs prefer a stepwise protection-deprotection approach to guide the halogens into meta positions. After reaction, the crude mixture needs purification, often by crystallization or column chromatography. Researchers look for consistent melting points and spectral matches (NMR, IR) to confirm success. These days, greener bromination approaches cut down on waste bromine and push for milder media, reducing risk to the operator and the environment.

Chemical Reactions & Modifications

The two bromines have a lot of chemistry up their sleeve. Run 1,3-dibromobenzene through organometallic routes—say, treat it with magnesium shavings and you get the corresponding Grignard reagent, ready to snap up carbonyls or couple with alkenes. Chemists love the Suzuki-Miyaura coupling for building up biaryls, and this compound’s ready-made leaving groups simplify things. One can replace bromines via nucleophilic aromatic substitution, or sneak in amines and thiols if conditions are right. All these reaction tracks offer tools for crafting dyes, pharmaceuticals, and sensor molecules. There’s an instinctive satisfaction that comes with seeing well-behaved reactants, and 1,3-dibromobenzene ranks high for predictability.

Synonyms & Product Names

Catalogs and MSDS documents might list several names for this compound: meta-dibromobenzene, m-dibromobenzene, 1,3-dibromobenzol, or just DBB. IUPAC gives the nod to 1,3-dibromobenzene, but searching old research or commercial listings brings up these aliases. CAS Number 108-36-1 cuts through ambiguity and works for ordering or cross-referencing in regulatory files.

Safety & Operational Standards

Handling organobromines demands respect, whether in kilogram drums or micro-scale vials. 1,3-Dibromobenzene contains hazards if inhaled or absorbed; gloves, eye protection, and fume hoods become standard tools for keeping chemists healthy. Storage means dark, cool, and well-ventilated environments, separated from strong bases or reducing agents that could cause a mess. Industry often looks to OSHA, REACH, and GHS for the rules—training and signage reduces the chance of accidents. Spill kits, eye stations, and first-aid info stand at the ready in labs working with meaningful quantities. Working with brominated solvents teaches caution, and everyone benefits when risk management is taken seriously.

Application Area

The influence of 1,3-dibromobenzene runs through sectors like pharmaceuticals, where halogenated rings seed plenty of lead compounds. Dye manufacturers rely on this intermediate to create pigments with vibrant, permanent color. Polymer scientists use it to tweak thermal resistance and add heft to specialty plastics or films. In electronics, its derivatives help tune dielectric properties for new materials in flexible circuits. University researchers use it to teach advanced synthetic concepts, and industrial chemists keep it handy for scaling up new reactions. Its chemistry sits at the intersection of reactivity, availability, and cost-effectiveness.

Research & Development

The story of 1,3-dibromobenzene in research isn’t finished. Every year brings new publications exploring its role as a cross-coupling partner or as a building block in materials science. Graduate students and research staff stress-test its properties, refining reactions for efficiency or exploring new function in sensors and organometallic frameworks. Lab notebooks fill up with results of reactions under microwaves, flow reactors, or biocatalytic procedures, as greener chemistry takes center stage. Computational chemists help by predicting reactivity profiles, which shaves precious weeks off project timelines. Industry moves fast on scalable syntheses, incorporating automation to drop both cost and labor.

Toxicity Research

Not all halogenated aromatics are safe, and 1,3-dibromobenzene sits under constant review. Acute exposure studies in rodents flag moderate toxicity; symptoms include dizziness and irritation if handled carelessly. Chronic data show some organ impact after large or repeated doses, pushing for strengthened precautions in the workplace. Environmental impact looms as a concern, with improper disposal leading to persistent organic pollutants. Regulatory bodies look for evidence of carcinogenicity or reproductive harm, prodding manufacturers toward best practices in packaging and labeling. MSDS sheets reflect the latest science, and updates spread quickly thanks to electronic databases. Safety remains a moving target because new data can change guidance and handling protocols year to year.

Future Prospects

1,3-Dibromobenzene’s story doesn’t look like it’ll close anytime soon. Future research points toward more selective functionalizations, where chemists swap bromines for exotic groups with lasers, enzymes, or renewable catalysts. As sustainability becomes a core driver in chemical manufacturing, labs and factories alike will search for less hazardous bromine sources and closed-loop systems to cut emissions and waste. In electronics and advanced polymers, the value of fine-tuned halogenation grows as new device requirements emerge. Regulatory shifts push for safer alternatives, but clever chemistry keeps 1,3-dibromobenzene relevant—retooled production lines and increased recycling may extend its useful lifespan, while R&D teams scour its structure for new reactivity paths. Its place in textbooks and market lists looks secure for now, but everyone in the field keeps looking around the next corner for safer, smarter, or more sustainable ways to produce and use this classic compound.

An Everyday Chemical with a Specific Purpose

Walk into a chemistry lab and you’ll spot all sorts of bottles with unfamiliar names. 1,3-Dibromobenzene sits among them, a colorless or pale yellow liquid that never really gets attention outside certain circles. Its story, though, touches a lot more people than you’d think. It’s not famous, but it’s there, shaping science in the background.

The Role in Building Bigger, Better Molecules

1,3-Dibromobenzene pops up most often when chemists want to build something new. It sounds simple, but the process of constructing molecules relies on a kind of chemical scavenger hunt, hunting for building blocks that stick together in specific ways. With those two bromine atoms perched on the benzene ring, 1,3-dibromobenzene lets researchers attach new parts in very targeted spots. This makes it handy in making pharmaceuticals, agricultural chemicals, or new polymers. The job these molecules do often depends on exact shapes and connections. Even a small error can tank a whole project.

A Helpful Hand in the Classroom

Organic chemistry classes often use 1,3-dibromobenzene as a teaching tool. Students practice classic reactions with it, watching as other chemicals swap in where the bromine sits. There’s value in using a reliable, predictable material. Mistakes show up clearly, and patterns are easier to see. A safe, known substance like this lets learners focus on understanding instead of fighting with unpredictable side effects.

Safety and Environmental Concerns

Handling 1,3-dibromobenzene isn’t all fun and games. Like many halogenated chemicals, it brings health risks. Skin contact leads to irritation and dizziness or headache if inhaled. Some studies raise flags on long-term exposure, so fume hoods and gloves come standard. Anyone using this chemical needs to take these warnings seriously—cutting corners on safety can lead to real trouble for workers, students, and the environment. Improper disposal can affect water sources and wildlife, making labs responsible for their waste. Regulations often require documentation for both use and disposal, reminding everyone that chemistry never happens in a vacuum.

Why It Matters

Some people see chemistry as distant, more about textbook formulas than everyday decisions. But the research that happens today with 1,3-dibromobenzene paves the way for new medicines, materials, and cleaner energy in the future. Finding alternatives sometimes comes up, especially for applications in larger quantities. Green chemistry efforts look for safer, non-halogenated molecules to do the same job without the same risks. Real progress means balancing usefulness with health and environmental impact. It’s this constant reassessment—using what works while searching for safer answers—that keeps science grounded and people safe.

Looking Forward

Anyone who’s worked with chemicals learns early that nothing stays static. Alternatives will keep creeping up, sometimes replacing staples like 1,3-dibromobenzene, sometimes sticking around for another generation. The tools may change, but the goal is always the same: build something better, do less harm, and respect the responsibility that comes with a powerful scientific toolbox.

Getting to the Core of Chemical Identity

Chemistry shapes much of the world around us. Growing up, I remember sitting at a kitchen table, fascinated by stories of scientists who could tell so much about a compound just by looking at a formula. Molecules do not just build products; they give us insight into how things act, how they break down, and even how safe or risky they can be for our bodies and the environment.

1,3-Dibromobenzene falls straight into that tradition of simple, powerful molecules. Its molecular formula is C6H4Br2, which spells out six carbon atoms, four hydrogen atoms, and two bromine atoms joined up in one ring structure. Each of those atoms has a job, and swapping any one of them changes a whole lot about the compound.

Why the Formula Matters in Practice

Formulas do more than fill up a line in a textbook. Walk into a chemistry lab or step onto a production floor in the pharmaceutical industry, and every bottle, tub, and flask gets checked again and again for the right compound—starting with its formula. C6H4Br2 tells the chemist exactly what to expect: one benzene ring with two bromine atoms attached at specific spots (positions 1 and 3). A single mistake in the type or spot of an atom throws off chemical reactions. It can even make a safe substance hazardous or unusable.

People sometimes forget that switching even a hydrogen for a bromine flips physical properties, toxicity, and usefulness. 1,3-Dibromobenzene, for example, finds its way into organic synthesis as a building block for more complex molecules in pharmaceuticals, agricultural chemicals, and dyes. Its formula lets researchers search scientific databases quickly, avoiding nasty surprises that might happen by confusing it with similar chemicals.

Human and Environmental Safety Hinges on the Details

No detail about a chemical’s makeup gets taken lightly. Both bromine atoms in this molecule increase its stability, which makes it a helpful stepping stone in manufacturing, but those same properties also call for careful handling. Br2 groups tend to linger if released unintentionally into human surroundings or waterways. Reports from environmental health agencies keep warning us about the impact of brominated organics. Knowing the exact formula helps regulators flag risks, set safe exposure limits, and develop cleanup plans.

Building Better Science Through Accurate Information

On a personal note, I once worked on a project involving aromatic compounds and learned fast that a single error in a molecular formula led to wasted weeks and a stack of repetitive safety paperwork. One misplaced hydrogen or a miscounted carbon atom derails a whole experiment. Using precise information, double-checking against reliable literature, and keeping good safety records save headaches and prevent lab accidents.

Trust in science starts with small details like C6H4Br2, and it trickles down to everything that follows—in research, industry, and public safety. Every molecular formula stands as a shorthand story of nature, risk, and potential.

Why Caution Matters with 1,3-Dibromobenzene

Working around chemicals, even those that seem familiar, always comes down to respecting what you’re handling. 1,3-Dibromobenzene isn’t a household name, but in research labs and some industrial settings, it plays a part in making dyes, pharmaceuticals, and flame retardants. As a benzene derivative, it brings certain risks to the table. Benzene and its family pose health threats, and bromine compounds aren’t known for their gentle nature either. Experience in shared college labs taught me pretty quickly—cutting corners doesn’t end well. Mistakes could mean anything from a burned palm to a call to poison control.

Essential Protective Gear

For anyone preparing to handle 1,3-Dibromobenzene, sturdy gloves and safety goggles come before all else. Nitrile gloves stand up better to organic solvents than latex. Splashing accidents can send droplets into the eyes, and even a small exposure can sting or damage eye tissue. A lab coat or chemical-resistant apron keeps this compound off your skin and away from regular clothing. Closed-toe shoes—sometimes forgotten—protect toes from spills. Remember, long hair should stay back, and sleeves work better when snug. Always keep a nearby eyewash station and shower clear of clutter in case disaster strikes.

Working Spaces and Ventilation

1,3-Dibromobenzene gives off fumes, especially during heating or mixing. The sharp odor itself is a signal to stay cautious. Work under a well-functioning fume hood every time, no matter how small the quantity. Even a single forgotten step or a draft could pull fumes into your breathing space. Never improvise with makeshift ventilation or a cracked window—it simply doesn’t cut it for chemical safety.

Handling and Storage Habits

Bottles and beakers should always carry clear, legible labels. Your sense of smell isn’t enough to distinguish this from dozens of lookalike liquids. Store 1,3-Dibromobenzene in tightly sealed containers, out of direct sunlight, and away from any heat sources. Keep it apart from anything reactive—strong oxidizers or alkali metals could set off bigger problems. Experienced lab workers never leave open containers unattended, not just for themselves, but for the folks who share the same workspace.

Clean-Up Routines and Emergency Preparedness

Spills happen, even to the careful. Quick access to absorbent pads, neutralizing agents, and proper waste containers helps keep a bad spill from becoming a chemical hazard. Paper towels and open trash bins won’t do the job. Disposal means collecting contaminated solids and liquids in properly labeled containers, then following local hazardous waste protocols—not pouring it down the sink. Keep emergency numbers handy, and make sure everyone around knows their role in cleanup before anything goes wrong.

Training and Awareness: The Human Factor

No substitute exists for up-to-date safety training, whether it’s a quick refresher before a new experiment or a yearly lab review. I remember hearing about a colleague who thought he could skip reading the new material data sheet. A minor drip on his hand turned into blistering and required a doctor’s visit. Those reminders stick, making you double-check your own habits. Keeping the lines of communication open with coworkers and supervisors helps spot hazards early and builds good habits for everyone in the room.

Smarter, Safer Chemistry

People who take time to respect their chemicals, use the right gear, and keep their workspaces tidy see fewer close calls. Smart projects start with a solid plan for storage, routine checks on protective equipment, and a culture that encourages speaking up about potential hazards. Good safety is something that grows, shaped every day by careful choices and looking out for the people working nearby.

Why the Melting Point Really Matters

Anyone who’s handled chemicals—whether in a college lab or a chemical plant—knows that knowing a substance’s melting point is more than just a trivial fact. For 1,3-dibromobenzene, the melting point comes in at about 86°C, which sounds unremarkable on its own. Still, the significance stretches far beyond this simple figure. In the world of organic synthesis, a dependable melting point separates a pure sample from a contaminated one. A lot of students, including me, have watched sample after sample fail in purity checks, all because a few degrees got shaved off the melting point, signaling something snuck in during preparation.

Real-World Impact in Research and Manufacturing

Most chemists use melting point data to check identity and purity. Skipping this step wastes time and resources. Take organic electronics, for example, where 1,3-dibromobenzene often acts as a building block for more complex molecules. If the material contains any leftover catalyst or moisture, the melting point changes—sometimes imperceptibly, sometimes dramatically. A small shift can mean major headaches down the line: incorrectly developed semiconducting materials, unresponsive electronic sensors, or even batch failures. Fact-checking these points with other published sources solidifies a material's reputation in scientific circles. According to the CRC Handbook of Chemistry and Physics, this compound consistently lands at the 86°C mark.

Lab Safety and Melting Point

Overheating compounds in the lab is one of those classic errors that tends to happen the moment attention drifts. Knowing exactly when a substance changes state protects both equipment and staff. For 1,3-dibromobenzene, those 86°C mean a defined safety boundary. I’ve seen flasks harden and crack from careless overheating—costing both time and cash. Reliable handling protocols, built around the melting point, save a lot of pain and confusion.

Problems Caused by Impurities

Anyone who’s seen the results of a failed recrystallization knows that even tiny traces of solvent or another substance can knock the melting point off target. For compounds like 1,3-dibromobenzene, a lower or uncertain melting value often acts like a bright red warning light. Research from peer-reviewed journals documents instances where improper handling led to impurity-laden samples, distorted data, and sometimes flawed publications. Using modern purification methods like column chromatography and repeated recrystallization can solve this, but those steps only work if the goal post—the correct melting point—stays clear.

Common Missteps and Practical Solutions

One consistent slip-up in both academic and industrial settings centers around instrument calibration. Melting point apparatus runs can drift, throwing off every reading if not routinely checked. Calibration with certified standards keeps everyone honest. Also, recording melting range (not just a single temperature) gives a better window into sample quality. Well-run labs invest in both new instruments and staff training to reinforce this procedure.

Taking another practical approach, clear labeling and batch tracking ensure that one batch’s melting point readings don’t get mixed up with another. Quality management systems make these steps routine, and I've seen firsthand how they let even a small lab run as smoothly as a much larger operation.

Conclusion

For anyone working with 1,3-dibromobenzene, pinning down the melting point at 86°C stands as a clear marker for quality, purity, and safety. Getting this detail right lets research progress and industry production hit their marks with less risk and better results.

Real Risks of Mishandling

1,3-Dibromobenzene gets used a lot in chemical labs and in the materials industry. It’s not one of those everyday substances you find under the kitchen sink, so the way it’s put away matters a whole lot. This compound gives off a strong, sometimes harsh aroma and forms white crystals. Those crystals might look harmless, but they present a health hazard if handled carelessly. People who’ve worked for years in labs know how often small slip-ups snowball into emergencies—an uncapped bottle, a poorly sealed cabinet, or just plain forgetfulness. Breathing in the dust or contacting the eyes or skin can quickly turn a routine day into a trip to the doctor.

Safe Storage as a Daily Habit

Taking shortcuts has a cost. Good chemical storage feels like second nature to seasoned lab folks. They don’t leave bottles on random benches or assume others will put them away later. Instead, they keep compounds like 1,3-dibromobenzene in tightly closed glass or plastic containers, labeling them clearly. These containers go straight into a cool, dry, and well-ventilated chemical cabinet, far from sunlight or heat sources. Heat can spark a chain reaction—1,3-dibromobenzene won’t just spoil if warmed, it might even increase the risk of releasing toxic fumes.

Keeping Incompatibles and Curiosity Apart

People who store mixed chemicals tend to overlook how one spill leads to another. Separating chemicals slows down that chain reaction. For 1,3-dibromobenzene, the biggest enemies are strong oxidizers. Storing it for long periods anywhere near nitric acid or peroxides isn’t just lazy—it’s dangerous. Any good safety officer will keep a tight system and separate shelves for organics and oxidizers. This detail doesn’t just keep the room tidy; those barriers prevent dangerous run-ins. Always store this compound above floor level and never below eye level, so a spill or a broken bottle doesn’t wind up impossible to reach safely.

Real-World Experience: Clear Labeling Works

Years in the lab teach one lesson again and again—labels save time, prevent confusion, and stop terrible mistakes. A clear, legible label showing the full name, hazard information, and date of receipt means nobody has to guess what’s inside the bottle. Chemical codes alone don’t cut it. This approach has saved teams from grabbing the wrong reagent during a rushed project. It helps everyone track the shelf life and decide when to dispose of aging stocks.

Handling Emergencies Before They Start

An overlooked cabinet, a loose lid, or forgotten shelf can turn into an emergency. That’s why trained teams keep chemical spill kits within arm’s reach. Staff know where to look for protective gloves and safety goggles and understand exactly which spills call for evacuation. Shared routines—daily checks, regular audits, and cleanup schedules—keep storage areas ready for the real work. Sprinkling baking soda around won’t fix a real spill, so proper planning beats luck every single time.

Making the Safer Choice Every Time

In a workplace where results and safety matter, everyone—from the most junior student to the head of the lab—pays attention to storage. Training never stops, and it’s not just about rules; it’s about keeping everyone healthy and projects on track. Respecting 1,3-dibromobenzene means storing it like you mean business. That’s what turns an ordinary day in the lab into another day everyone gets home safe.